Butter inhibitor for MTO (methanol to olefins) device alkaline washing towers and preparation method thereof

A butter inhibitor, alkali washing tower technology, applied in chemical instruments and methods, hydrocarbon purification/separation, hydrocarbons and other directions, can solve the problems of clogging the tray, low butter inhibitory effect, etc., to achieve uniform and stable state, inhibit Aldol condensation reaction, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

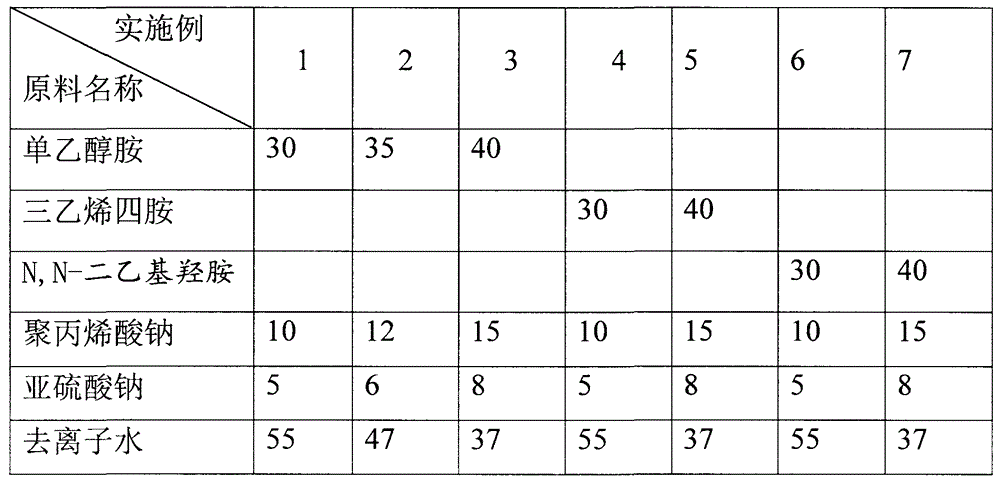

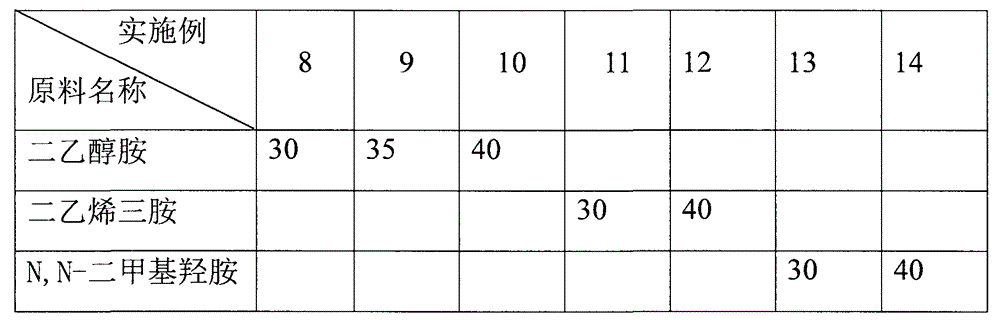

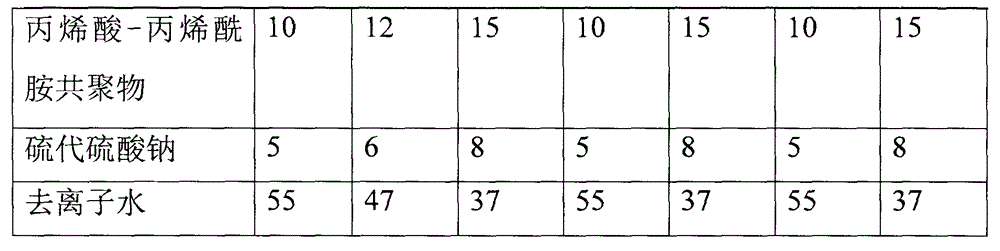

Method used

Image

Examples

Embodiment 15

[0049] The butter inhibitor in Example 1 is applied to the alkali washing tower of the MTO simulation device, the reaction raw material is methanol, the yield of ethylene and propylene is 78%, the concentration of sodium hydroxide in the alkali washing tower is 8%, and the inhibitor is added to the In the circulating lye, the filling amount is 100 μg / g relative to the reaction gas volume, and the device is operated for 20 hours to detect the amount of butter in the lye, and the amount of butter is reduced by 80% compared with the blank experiment.

Embodiment 16

[0051] The butter inhibitor in Example 7 is applied to the alkali washing tower of the MTO simulation device, the reaction raw material is methanol, the yield of ethylene and propylene is 78%, the concentration of sodium hydroxide in the alkali washing tower is 8%, and the inhibitor is added to the In the circulating lye, the filling amount is 100 μg / g relative to the reaction gas volume, and the device is operated for 20 hours to detect the amount of butter in the lye, and the amount of butter is reduced by 76% compared with the blank experiment.

Embodiment 17

[0053] The butter inhibitor in Example 12 is applied to the alkali washing tower of the MTO simulation device, the reaction raw material is methanol, the yield of ethylene and propylene is 78%, the concentration of sodium hydroxide in the alkali washing tower is 8%, and the inhibitor is added to the In the circulating lye, the injection amount is 100 μg / g relative to the amount of cracked gas, and the device is operated for 20 hours to detect the amount of butter in the lye, and the amount of butter is reduced by 65% compared with the blank experiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com