Method and device for measuring cross degree of rolling mill roll system

A measurement method and roll technology, which is applied in the field of hot rolling, can solve problems such as downtime and achieve accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

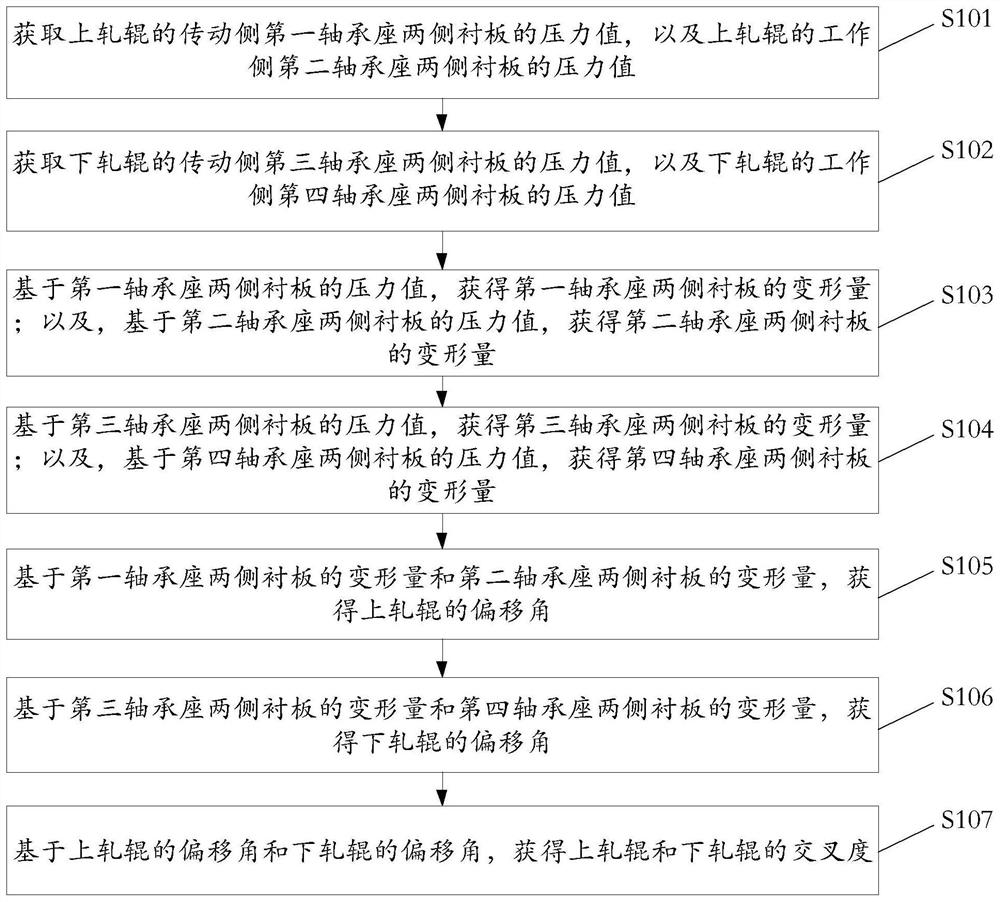

[0054] Such as figure 1 As shown, this embodiment provides a method for measuring the intersection degree of rolling mill rolls, which is applied during the operation of the rolling mill, including:

[0055] Step S101: Obtain the pressure values of the lining plates on both sides of the first bearing seat on the driving side of the upper roll, and the pressure values of the lining plates on both sides of the second bearing seat on the working side of the upper roll.

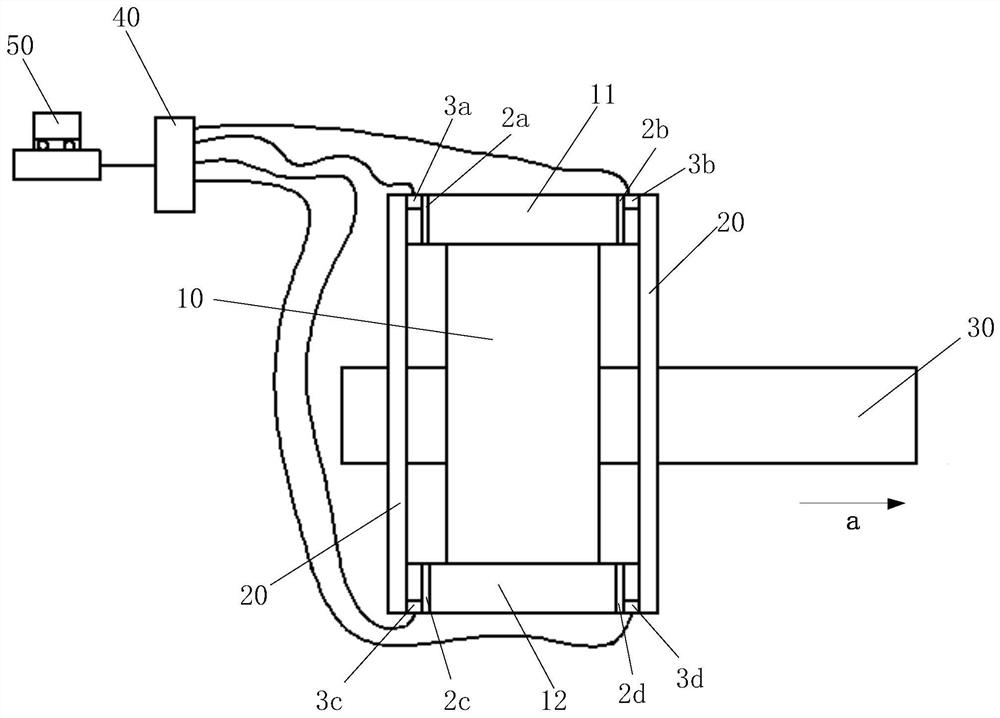

[0056] In a specific implementation process, the rolling mill involved in this embodiment may be a CVC rolling mill, which includes one or more sets of rolls, and each set of rolls is composed of an upper roll and a lower roll. In this embodiment, the degree of intersection between the upper roll and the lower roll in each set of rolls is mainly measured.

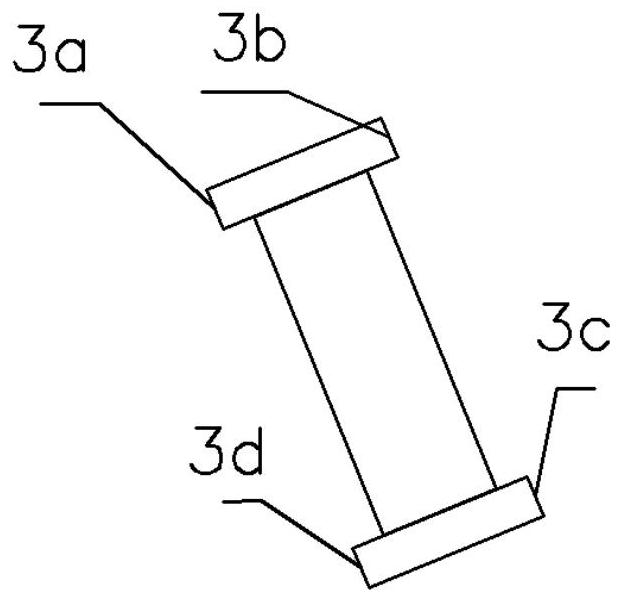

[0057] This embodiment adopts the principle of pressure piezoelectric induction to measure the pressure of the rolling mill roll chocks on the liner (ie:...

Embodiment 2

[0107] Based on the same inventive idea, such as Figure 5 As shown, this embodiment provides a measuring device 300 for the degree of intersection of rolling mill rolls, which is applied during the operation of the rolling mill and includes a memory 310, a processor 320, and a computer stored in the memory 310 and capable of running on the processor 320 Program 311. When the processor 320 executes the program 311, any method step in one of the foregoing embodiments may be implemented.

[0108] In a specific implementation process, the measuring device 300 for the intersection degree of the rolling mill roll system can specifically be figure 2 In the computer (ie: industrial control computer).

Embodiment 3

[0110] Based on the same inventive concept, this embodiment provides a computer-readable storage medium on which a computer program is stored, and when the program is executed by a processor, any method step in the above-mentioned embodiment can be implemented.

[0111] Those skilled in the art should understand that the embodiments of the present invention may be provided as methods, systems, or computer program products. Accordingly, the present invention can take the form of an entirely hardware embodiment, an entirely software embodiment, or an embodiment combining software and hardware aspects. Furthermore, the present invention may take the form of a computer program product embodied on one or more computer-usable storage media (including but not limited to disk storage, CD-ROM, optical storage, etc.) having computer-usable program code embodied therein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com