Steel wire drawing and releasing automatic tracing and controlling method and device for multi-wire cutting machine

A technology of multi-wire cutting machine and pay-off device, which is applied to fine working devices, control using feedback, and manufacturing tools, etc. To promote the application value, increase economic benefits, and improve the effect of machine reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment one: see figure 1 . The automatic tracking method for the steel wire in the automatic take-up and pay-off device of the multi-wire cutting machine of the present invention, the take-up and take-off device respectively adopts a servo motor, a gear and a rack to drive the mobile platform, and two contact wheels are installed on the mobile platform, and the steel wire Passing through the middle of the two contact wheels, the mobile platform drives the steel wire to move in the axial direction of the two wire wheels. The steel wire automatic tracking method of the present invention, by setting two rotary encoders linked with the contact wheels on the mobile platform, the rotary encoder The encoder shaft is connected to the contact wheel, and the output signal of the rotary encoder is connected to a controller through a wire. The position of the wire in the take-up and pay-off device, so that the steel wires are tightly and evenly arranged in the take-up and pay...

Embodiment 2

[0025] Embodiment two: see figure 1 . The steel wire automatic tracking method in the automatic receiving and unwinding device of the multi-wire cutting machine in this embodiment is different from the first embodiment in that: the rotary encoder sends an encoded signal and inputs it to the high-speed counter module of the controller, and each channel in the high-speed counter has A flag register, when the CPU processor detects that there is a count value, the flag position of the flag register is set to 1, otherwise it is set to 0, the CPU processor judges the flag bit of the flag register through the programming software, if the value of the flag bit of the flag register is 1, then pass The output module of the program controller sends a forward or reverse signal to control the forward or reverse rotation of the servo motor.

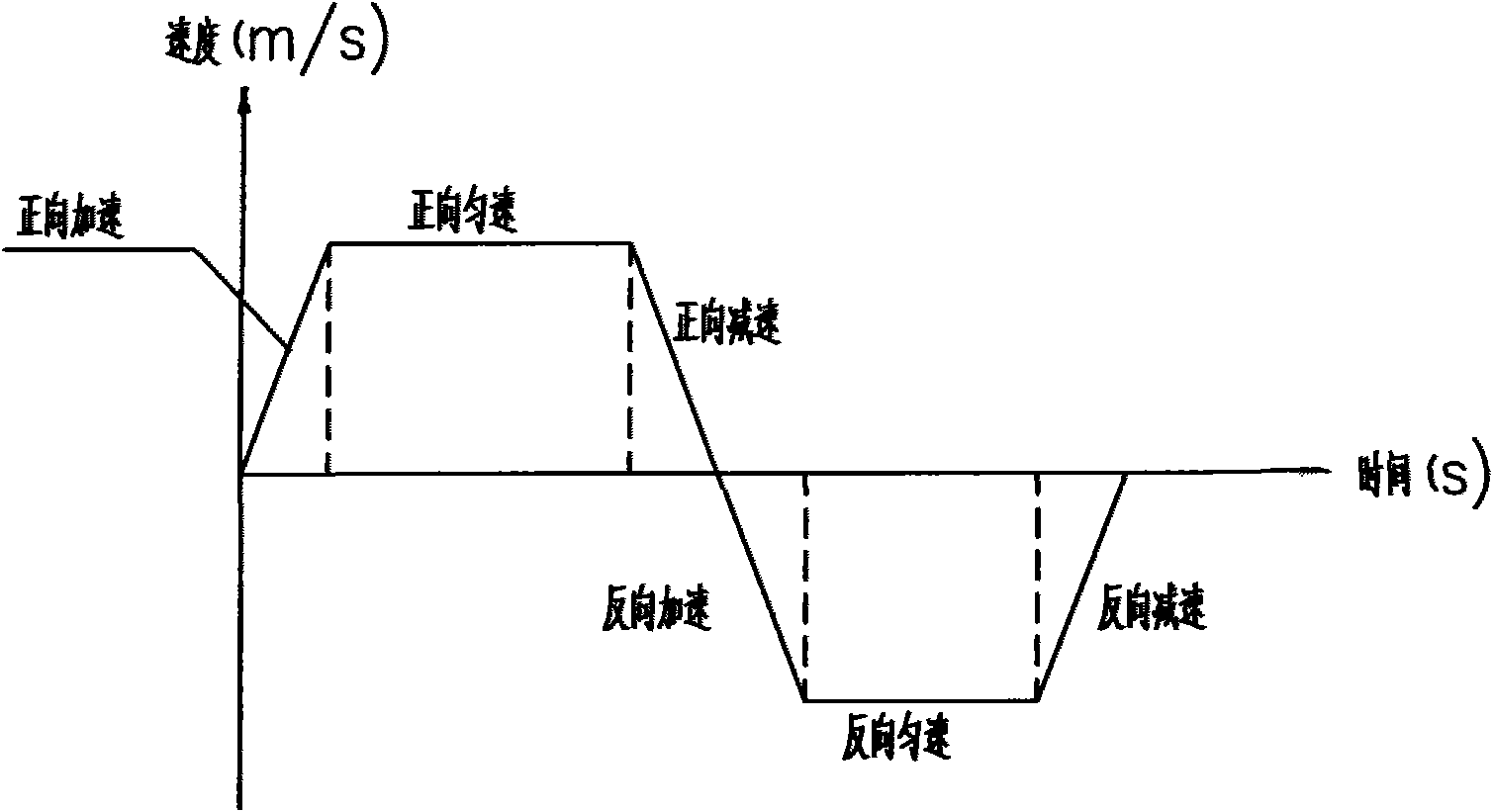

[0026] At the same time, the controller calculates the motion speed V of the servo motor according to the angular velocity ω of the wire wheel and t...

Embodiment 3

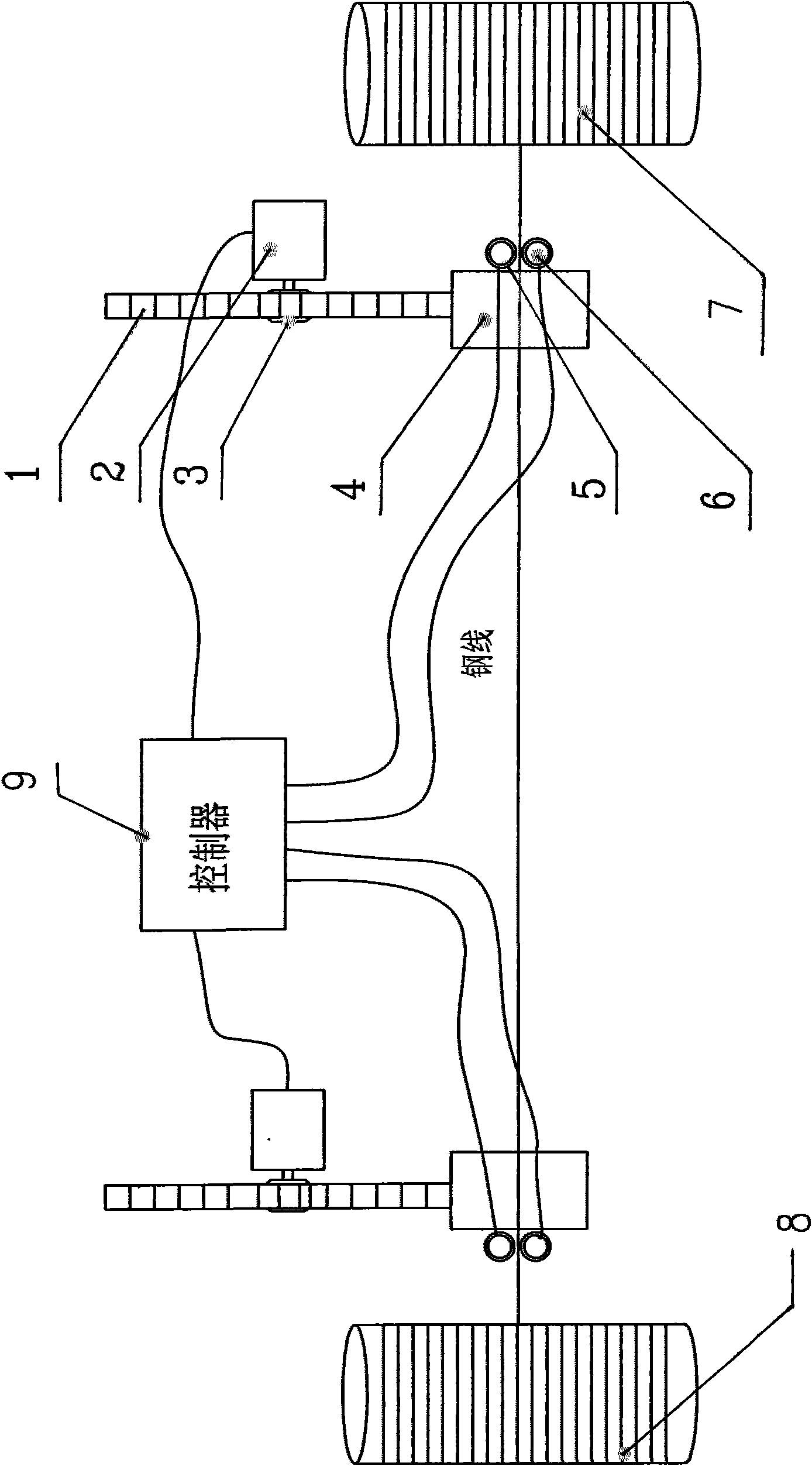

[0027] Embodiment three: see figure 2 . This embodiment is a specific implementation of the multi-wire cutting machine steel wire take-up and pay-off automatic tracking control device, wherein the take-up and pay-off devices all adopt a drive system including a servo motor 2, a gear 3, and a rack 1. Two contact wheels 5 are installed on the mobile platform 4 linked with the rack 1, and a rotary encoder 6 is respectively provided with each contact wheel on the mobile platform, and the coding shaft of the rotary encoder is connected to the contact wheels. , the output signal of each rotary encoder is connected to the controller 9, and the controller 9 controls and connects the servo motor 2. Among the figure, 8 is a pay-off reel, and 7 is a take-up reel.

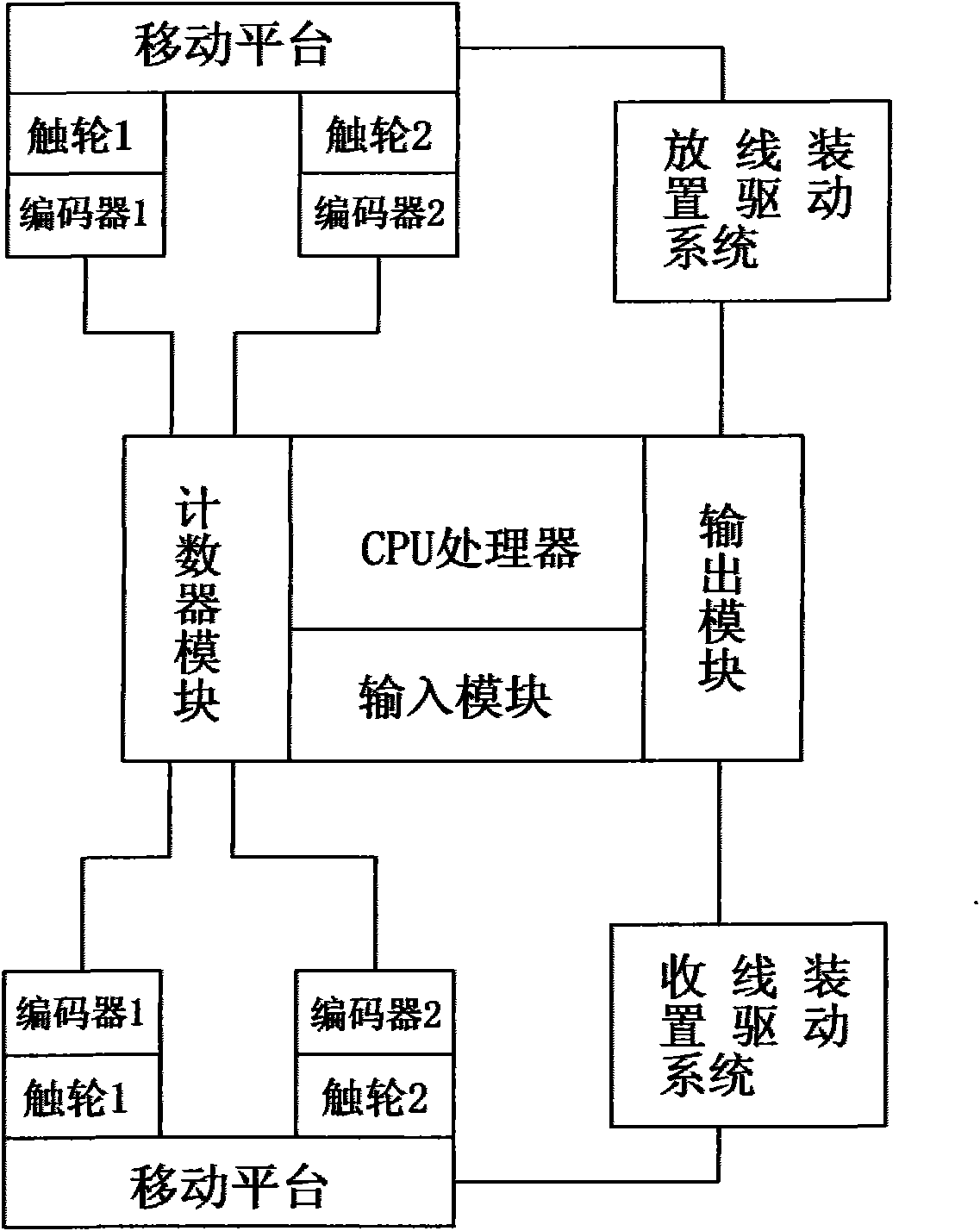

[0028]The controller of the multi-wire cutting machine steel wire receiving and paying-off automatic tracking control device includes a CPU processor, an input module, an output module, and a high-speed counter module. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com