Bottle mouth cutting mechanism of automatic bottle blow molding machine

An automatic blow molding and bottle blowing machine technology, applied in metal processing, household components, household appliances, etc., can solve the problems of damage to the air supply pipe, damage to the tool, and complex overall structure, so as to eliminate movement errors and ensure cutting quality , the effect of simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

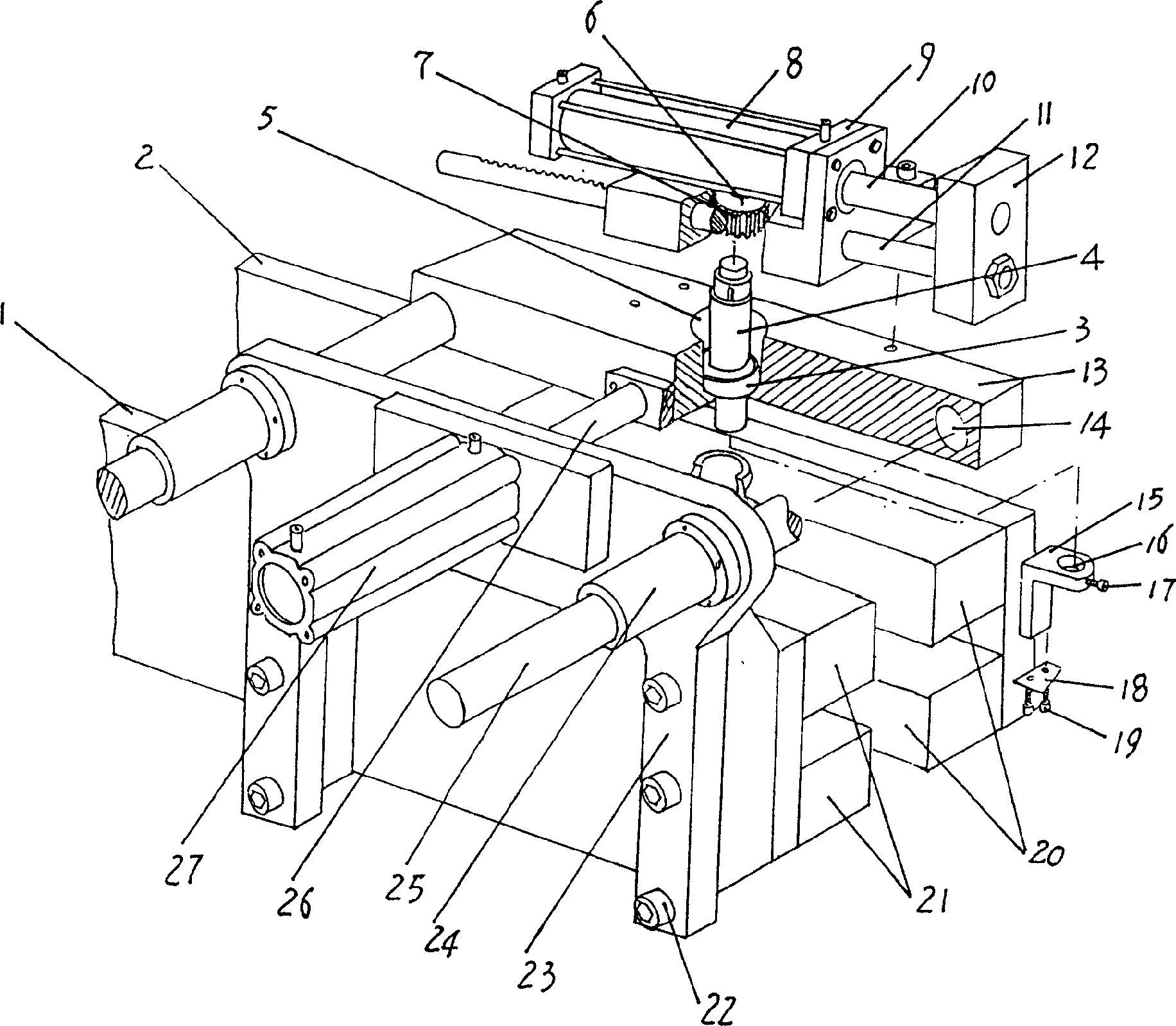

[0029] please see figure 1 and combine Figure 5 , the inner and outer mold connecting plates 2,1 of the bottle-holding device are respectively connected with the inner and outer templates 45,46 of the mold frame 42 of the automatic blow molding machine (see Figure 4 ), this connection can be realized with screws, or welding, etc. In this way, the inner and outer mold connecting plates 2,1 can be opened and closed with the opening and closing of the inner and outer templates 45,46 of the mold frame 42 of the automatic blow molding machine, and a pair of bottle half molds 20,21 face each other and can Dismountably be arranged on the inner side of a pair of inner and outer mold connecting plates 2,1, when the shape and specifications of the bottle 43 etc. change, then the bottle half molds 20,21 also change accordingly. figure 1 The bottle half-molds 20,21 shown in the illustration are only aimed at a certain kind of Figure 5 , Figure 8 For a bottle 43 of the specified si...

Embodiment 2

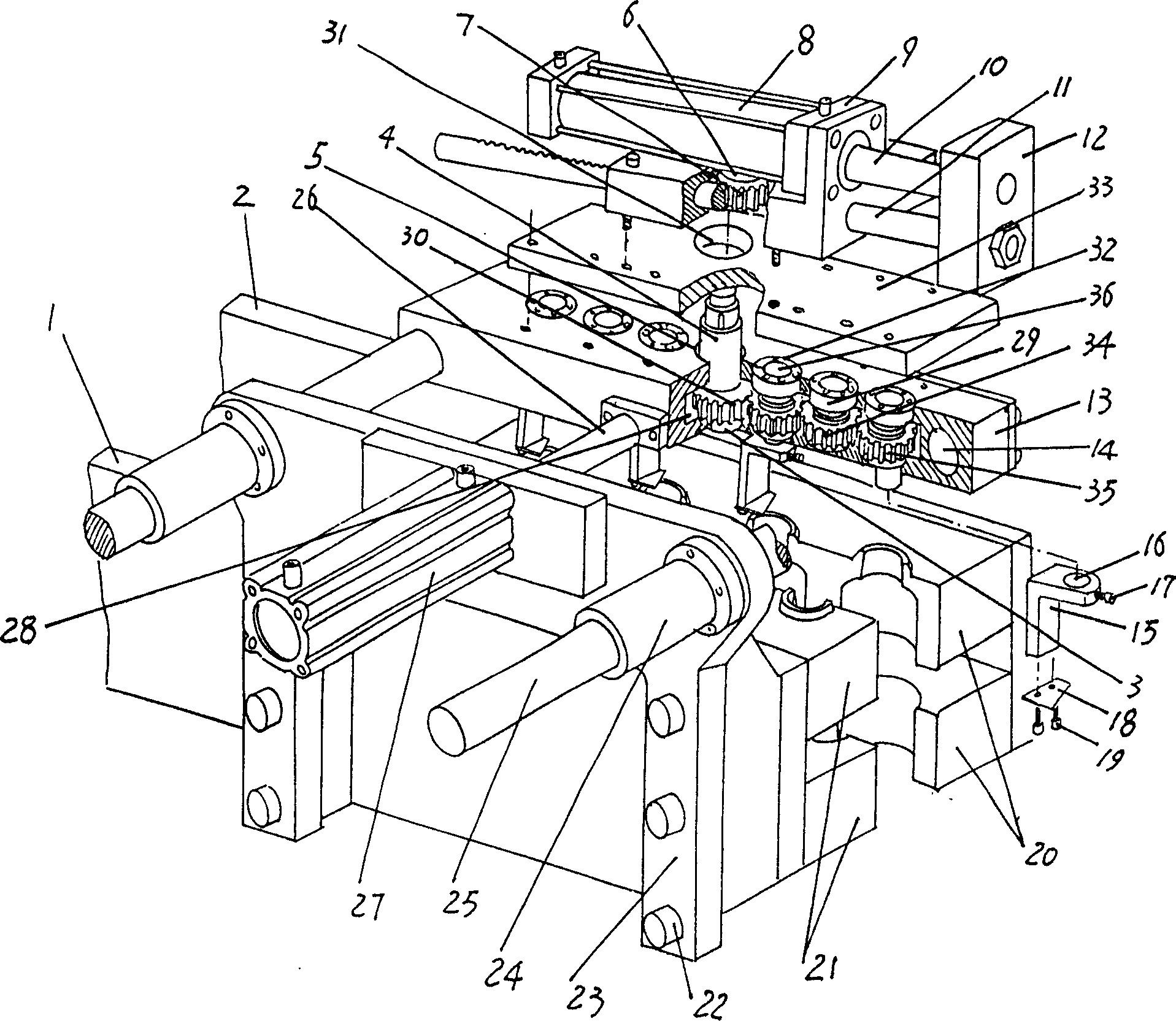

[0033] please see figure 2 and Figure 6 , the structure of this embodiment is an expansion of the structure disclosed in Embodiment 1. This expansion is mainly reflected in the change of the moving seat 13 and the central gear 30 is set at the lower end of the central shaft 4, and a moving seat 13 is formed. The hollow seat cavity 28 becomes a gear box-like structural form by arranging the corresponding components to be mentioned below, and the rest are still the same as in the first embodiment. There are also two groups of rotary cutter shafts 36 belonging to the flash cutting device on the mobile seat 13, and each group of rotary cutter shafts 36 has at least one pair, and a rotary cutter bar 15 is affixed to the bottom of each rotary cutter shaft 36. In this case, the lower end of the central shaft 4 may or may not be provided with the rotary cutter bar 15, and it is necessary to add a central gear 30. Two groups of rotary knife shafts 36 are shown in the figure, each g...

Embodiment 3

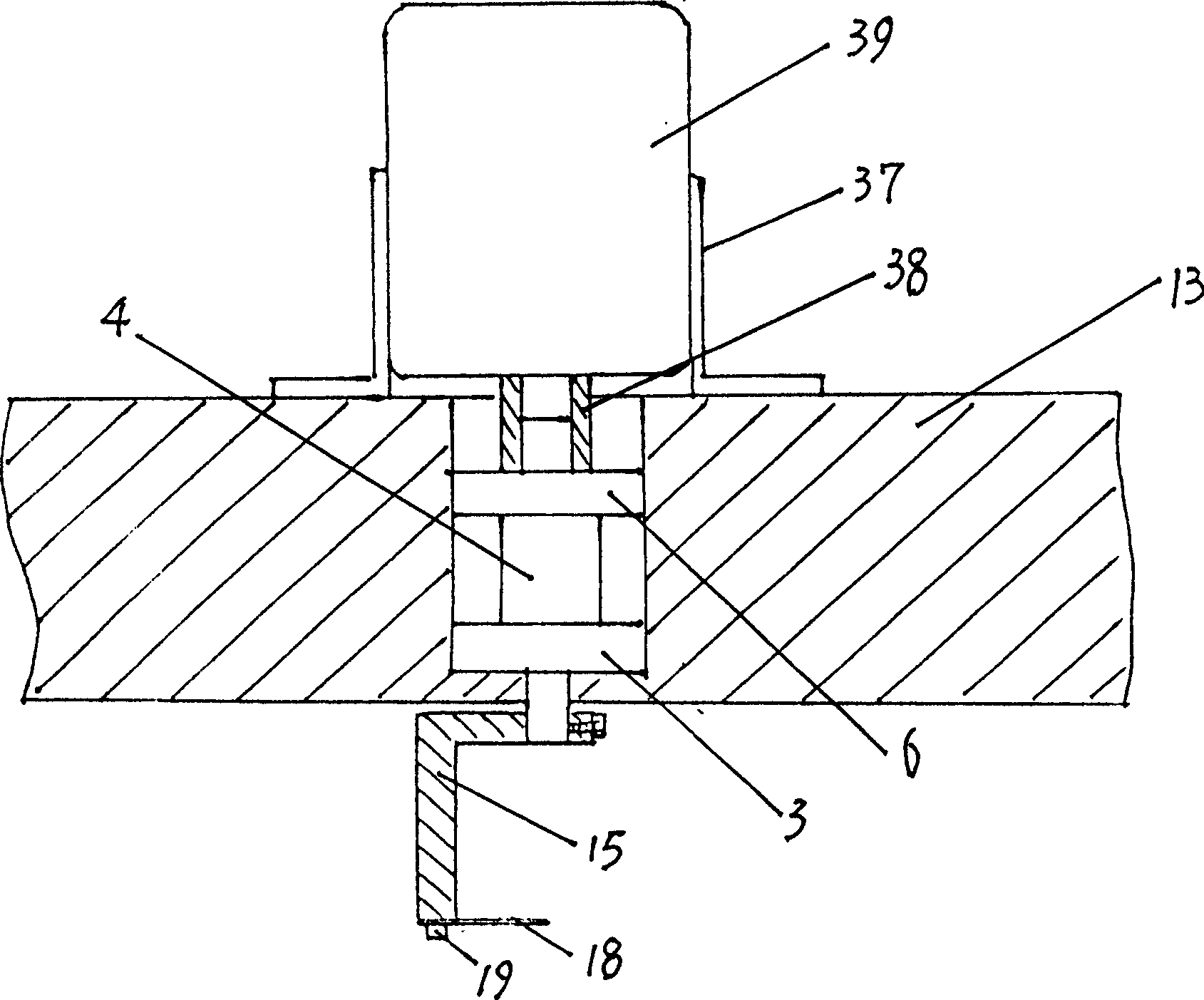

[0035] please see image 3 and Figure 7 , In this embodiment, the central shaft driving mechanism for driving the central shaft 4 to rotate is changed to adopt a stepper motor 39, and the rest are the same as in Embodiment 1 or 2. The stepping motor 39 is located on or claims to be seated on the moving seat 13 through a bracket 37, and the output shaft of the stepping motor 39 is connected with the central shaft 4 through a coupling 38, and the central shaft 4 is still supported by a pair of bearings 6,3. Realize being pivotally placed on the mobile seat 13. Compared with Embodiment 1 and Embodiment 2, the structure of this embodiment is simpler in structure and cheaper in cost.

[0036] Figure 8 It shows the situation after the bottle mouth burr 44 of the bottle 43 is cut off through the implementation of Examples 1, 2, and 3.

[0037] Applicants choose figure 2 , 6 and combine Figure 4 Describe the process that the present invention cuts off the bottleneck flash 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com