Vacuum adsorption device of battery pole piece

A battery pole piece, vacuum adsorption technology, applied in welding equipment, laser welding equipment, metal processing equipment and other directions, can solve the problems of inconsistent scale depth, uneven surface of the pole piece, affecting the cutting effect, etc., to avoid scratches, structure Simple, long-life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

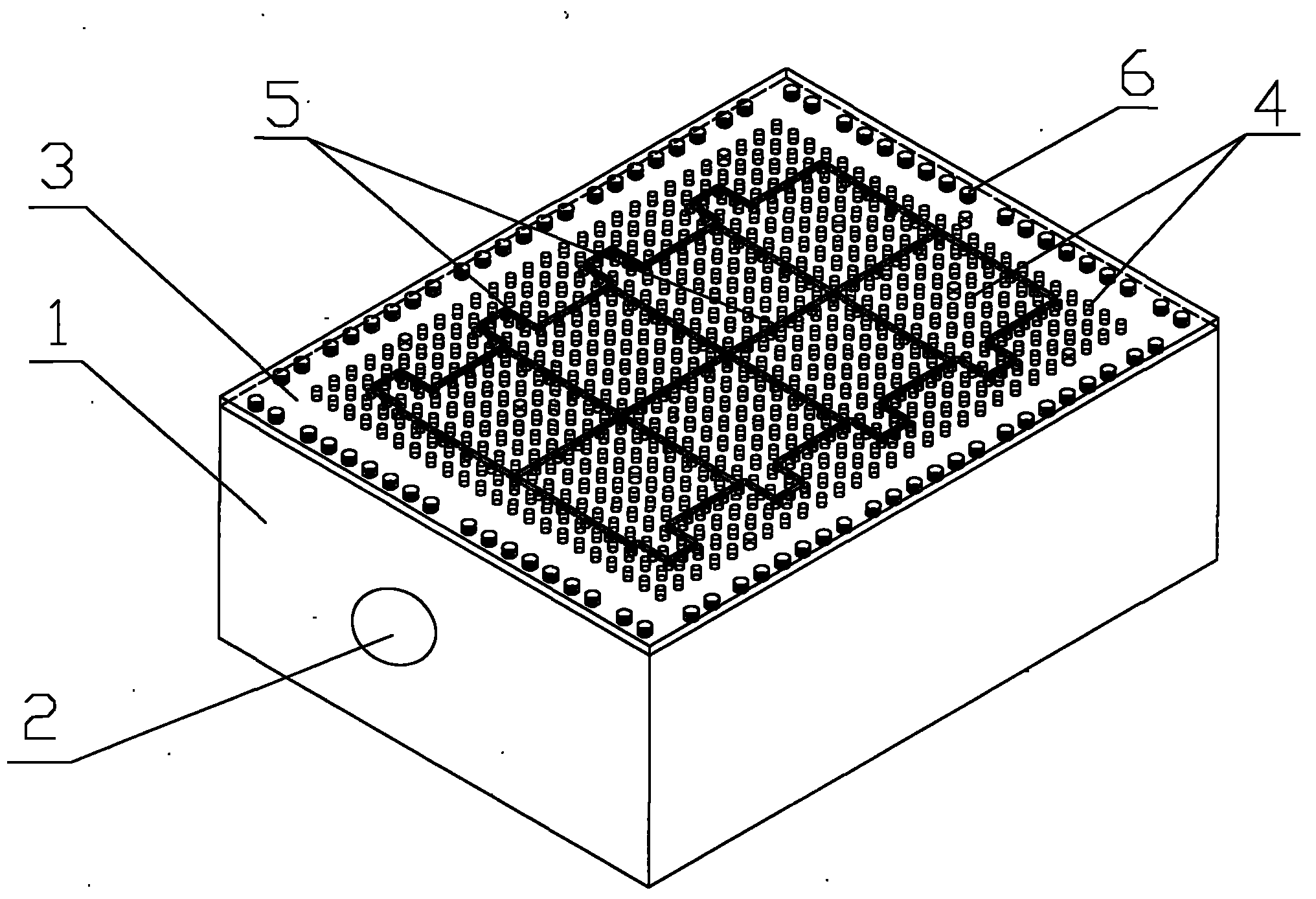

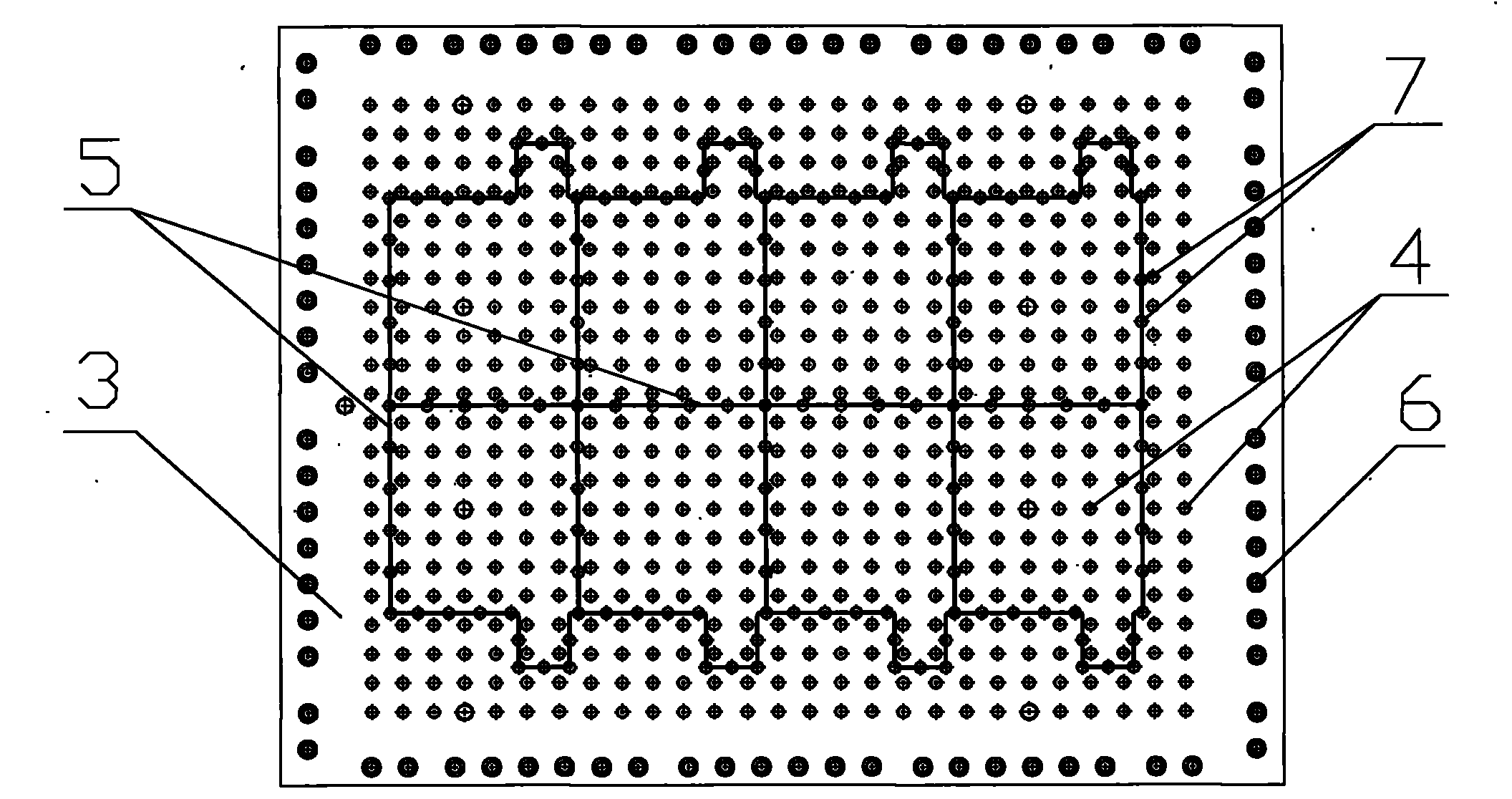

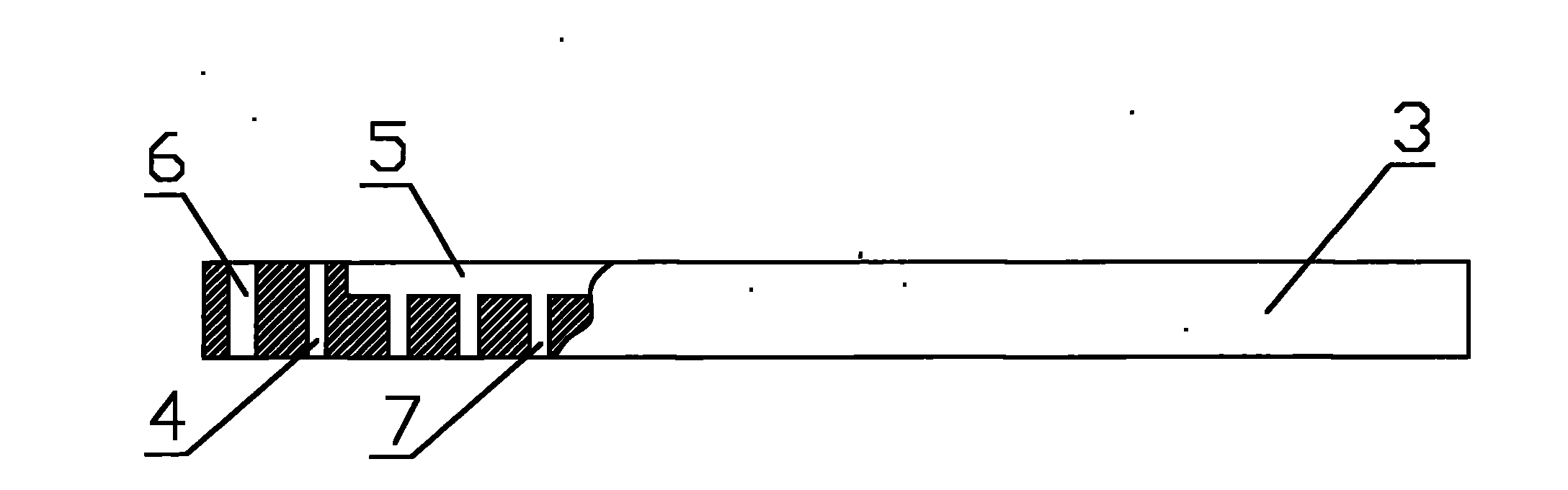

[0019] Such as figure 1 , 2 , 3, the battery pole piece vacuum adsorption device of this embodiment includes a closed cavity 1, and the cavity 1 is provided with an exhaust hole 2 for communicating with the vacuum generator. The key is that the top of the cavity 1 The surface is a planar substrate 3 provided with a plurality of adsorption through-holes 4 arranged in an array. The substrate 3 is provided with a concave avoidance groove 5 along the cutting line of the battery pole piece. The depth of the avoidance groove is greater than 1 mm; the space-avoiding groove 5 is provided with a plurality of through holes 7 arranged at intervals to facilitate the cleaning of dust generated during laser cutting.

[0020] The surface of the substrate 3 is made of elastic rubber to prevent damage to the coating layer on the surface of the battery pole piece and affect the quality of the battery pole piece.

[0021] Mounting holes 6 are provided around the base plate 3, and the base plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com