Automatic slack bobbin winder

A loose winding machine, automatic technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve problems such as uneven dyeing of tight-sided bobbins, unreasonable connection design, and complex anti-folding design. , to achieve the effect of sensitive and accurate judgment, self-stop function of yarn breakage, improvement of work efficiency and economic benefits, and simple connection design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

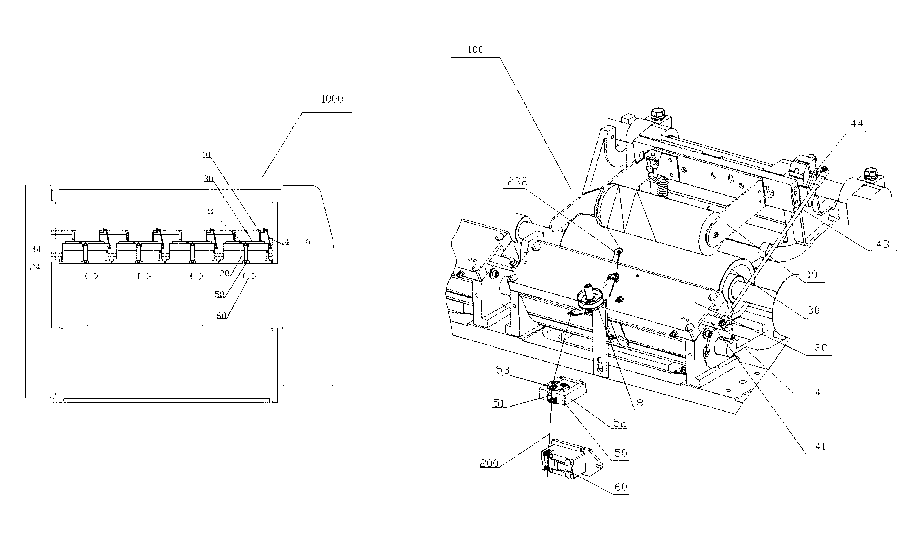

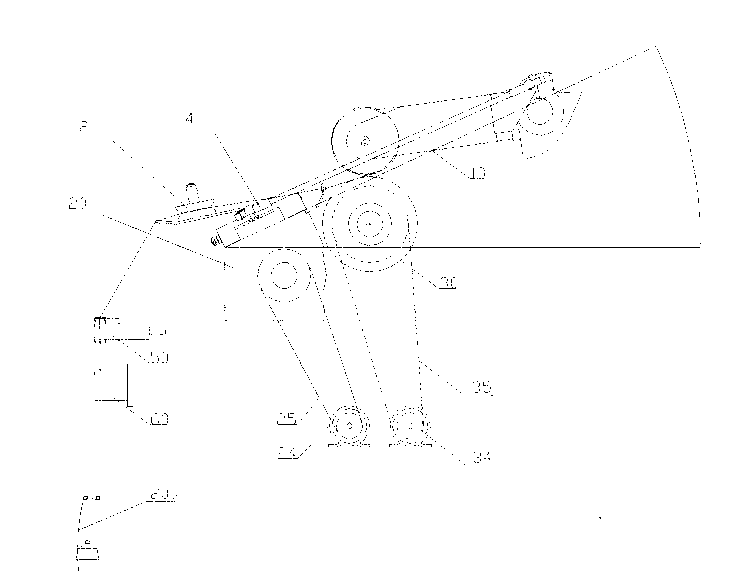

[0040] Such as Figure 1 to Figure 10 Shown is a preferred embodiment of the present invention.

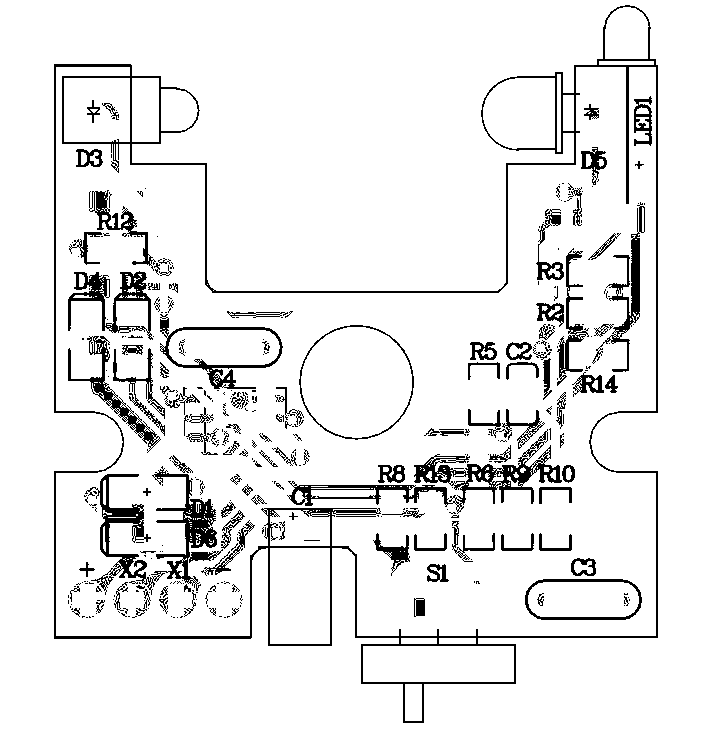

[0041] Such as figure 1 , figure 2 , Figure 4 , Figure 7 , Figure 10 The shown automatic loose winder 1000 includes a winding device 1 set on the frame and driven by a friction roller motor and a grooved drum motor, a luffing yarn guide device 4, a fixed length control device 5, a tension adjustment The device 8 and the host control device 9. The winding device 1 includes a winding stand 10 , a drum 20 and a friction roller 30 . The bobbin bobbin core 133 clamped by the winding frame 10 does not rotate itself, but clings to the friction cylinder to drive the bobbin to perform circular motion by the friction force generated by the rotation of the friction cylinder. There is a device connected to the winding switch of the rewinder on the back of the winding frame 10, and a device that can support the lifting position of the winding frame and other functions. When the wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com