Sawing wire cutter for cave mining of mineral materials and cave mining method for mineral materials

A kind of cutting equipment and sawing rope technology, which can be used in open-pit mining, earth drilling, special mining, etc., and can solve problems such as complex, uneven cross-sections, and fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

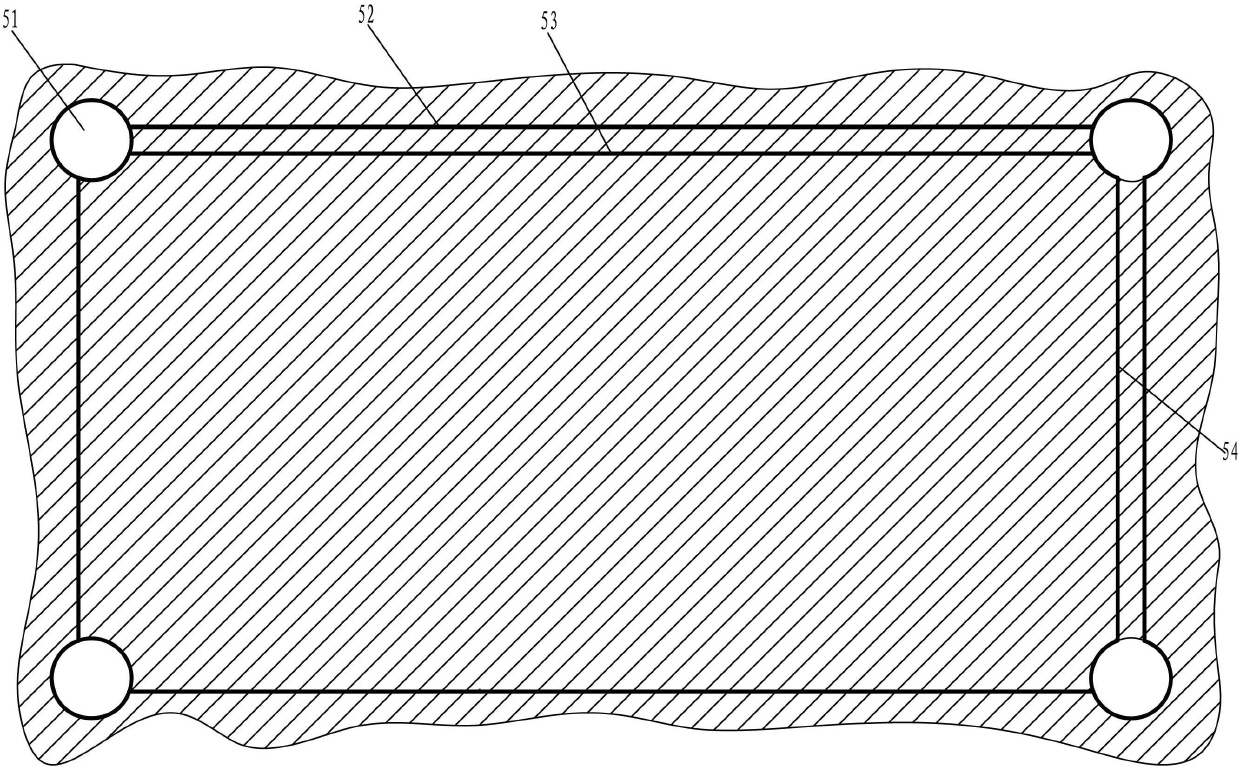

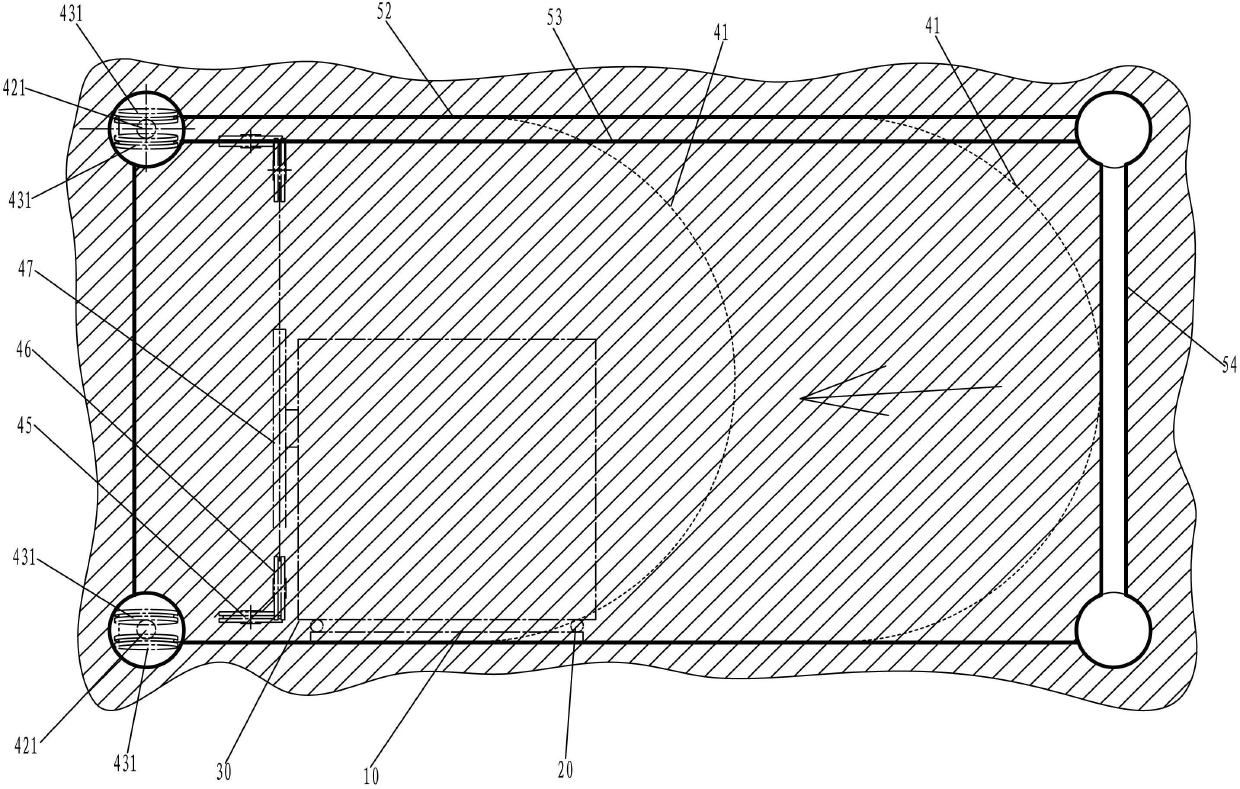

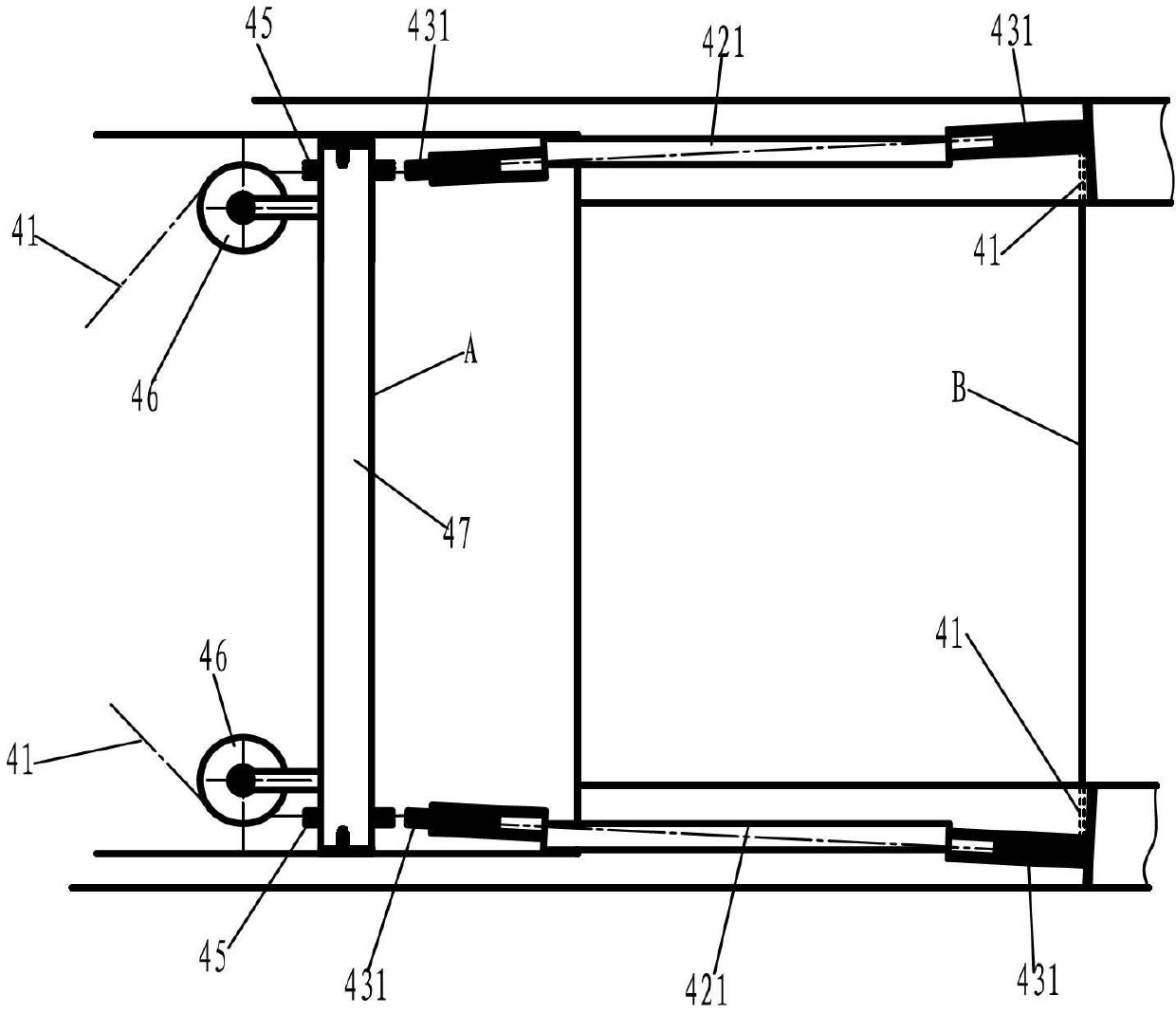

[0058] Please check Figure 1 to Figure 11 , the saw wire cutting equipment used for mineral cave mining, it includes a support 10, a guide rail 20, a main motor 30, a feed device and a saw wire cutting mechanism. The support 10 can be installed on the working surface A. The guide rail 20 is mounted on the bracket 10 . The main motor 30 can be slidably connected to the guide rail 20 . The feeding device is mounted on the bracket 10 and connected to the main motor 30 to drive the main motor 30 to feed relative to the guide rail 20 , for example, the motor cooperates with a transmission mechanism to drive the main motor 30 to feed relative to the guide rail. In this embodiment, the working surface A is, for example, the outer free surface, and the cutting surface B is the back facing surface, that is, the working surface A can be parallel to the cutting surface B, but this is not taken as an example. , as needed, they can also intersect.

[0059] The wire saw cutting mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com