Electronic element automatic welding equipment

An electronic component and automatic welding technology, which is applied in the direction of welding equipment, welding equipment, resistance welding equipment, etc., can solve the problems of poor product consistency, low efficiency, and overall quality of electronic components, so as to improve production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

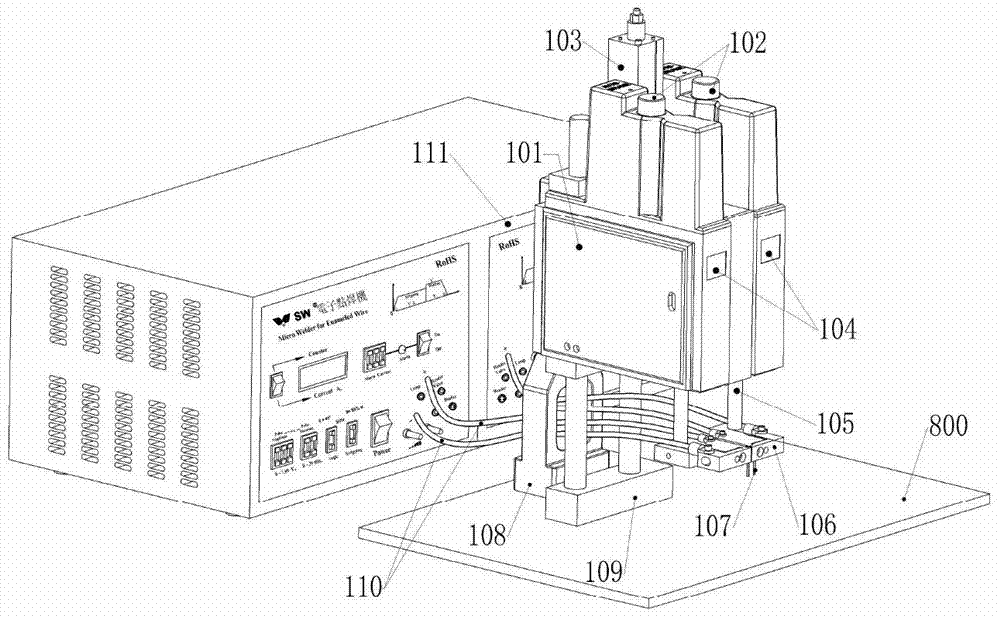

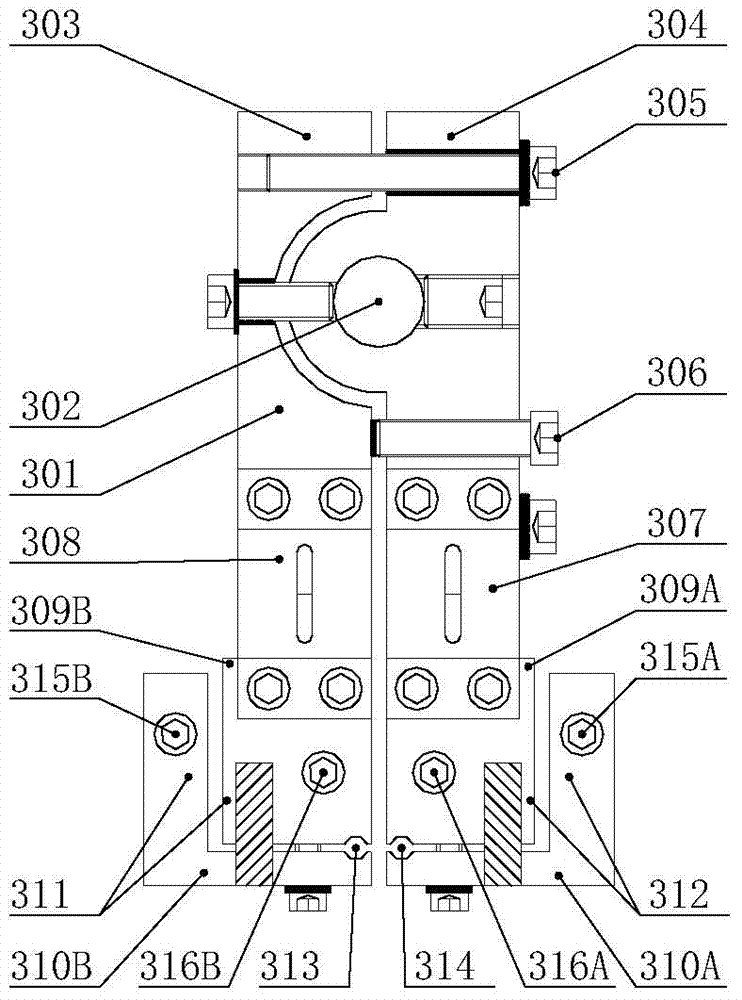

[0036] 2, the parallel electrode welding head with thread cutter; 3, dispensing device; 4, four parts of content introduction the present invention of electronic component automatic welding production equipment below.

[0037] 1. First combine figure 1 Introduce the contents of the spot welding testing device in the preferred embodiment of the present invention.

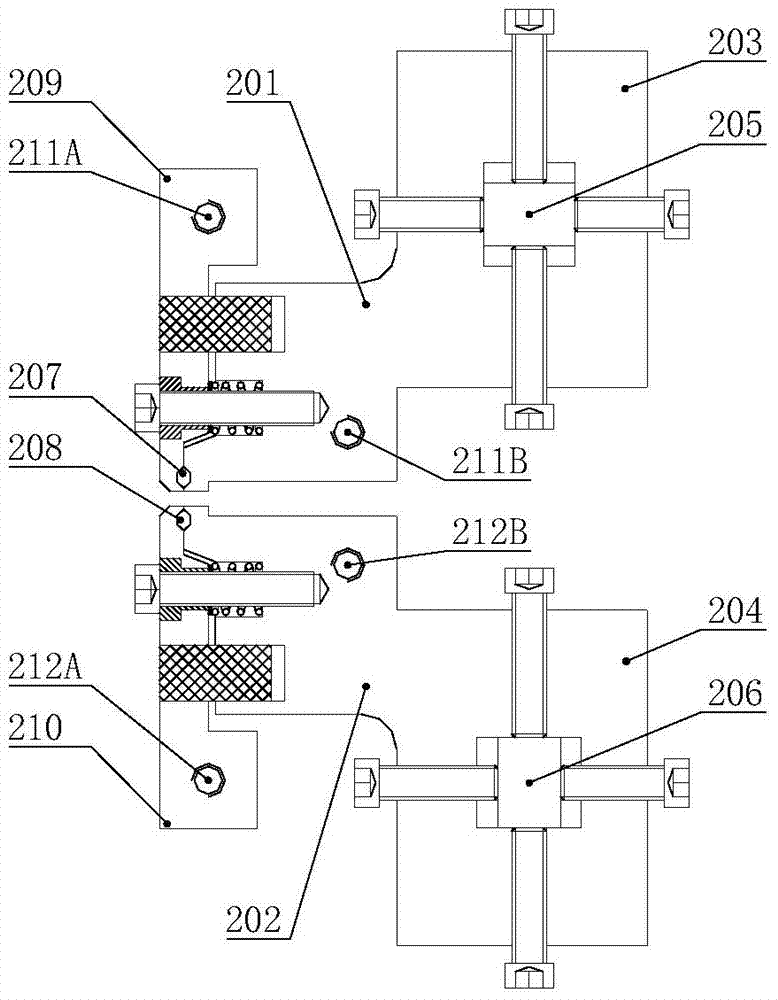

[0038] The spot welding testing device is used to implement the spot welding process, the disconnection process and the testing process at the same time. In order to implement the above three processes, the device includes two welding head clamps arranged side by side and the spot welding head connected thereto, spot welding power supply, and detection circuit. The two welding head clamps are respectively equipped with parallel electrode welding heads and passed the installation The spot welding head of the Z-axis power device drives the welding and disconnection of the electronic components; while the welding is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com