Charged wire stripping device

A wire stripping device and wire stripping technology, which is applied in the direction of cable installation device, cable installation, electrical components, etc., can solve the problems of live stripping work space limitation, insulated wire live connection effect is poor, etc., to achieve high stripping efficiency and fire protection Good effect and reliable electrical connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

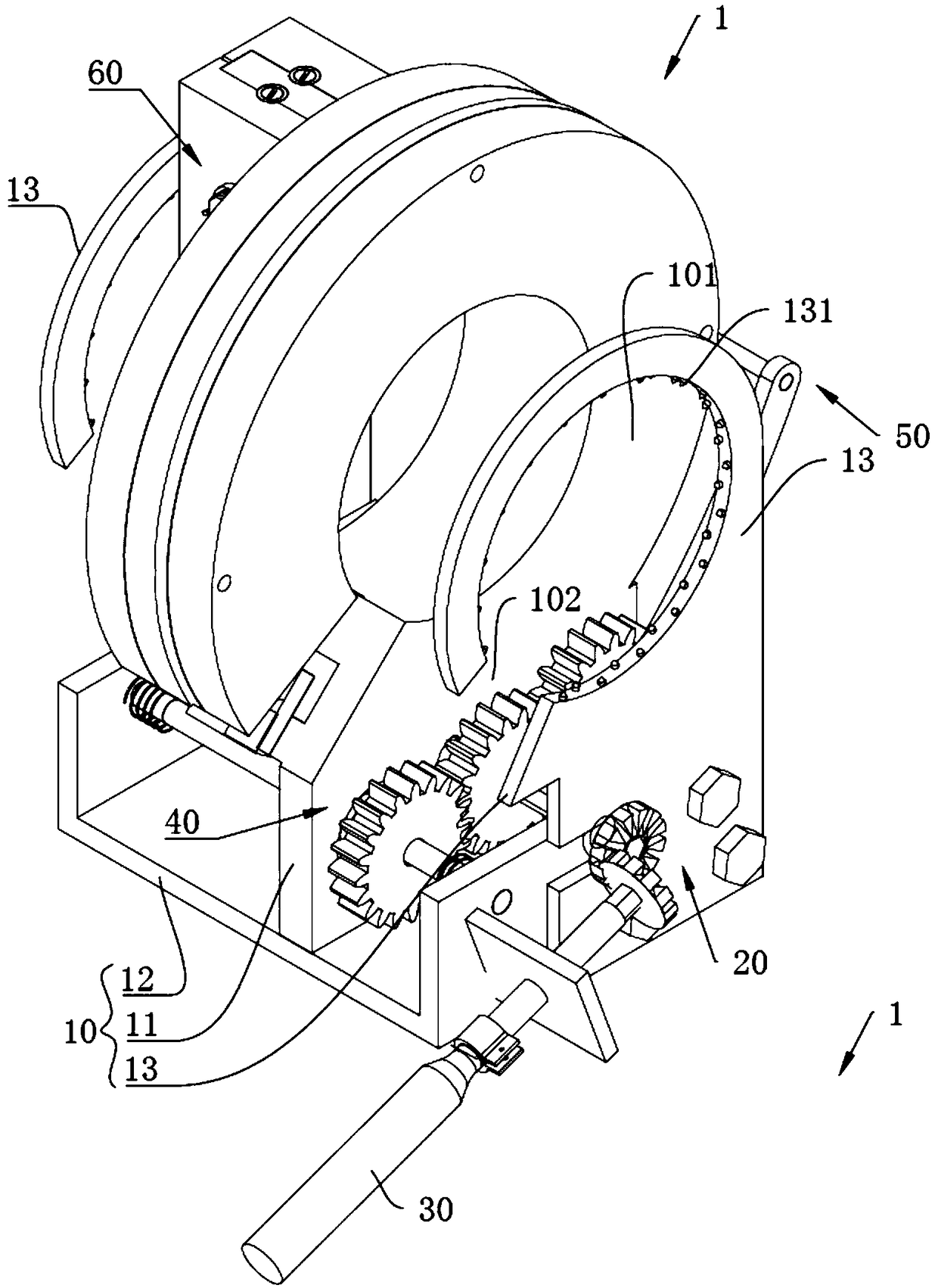

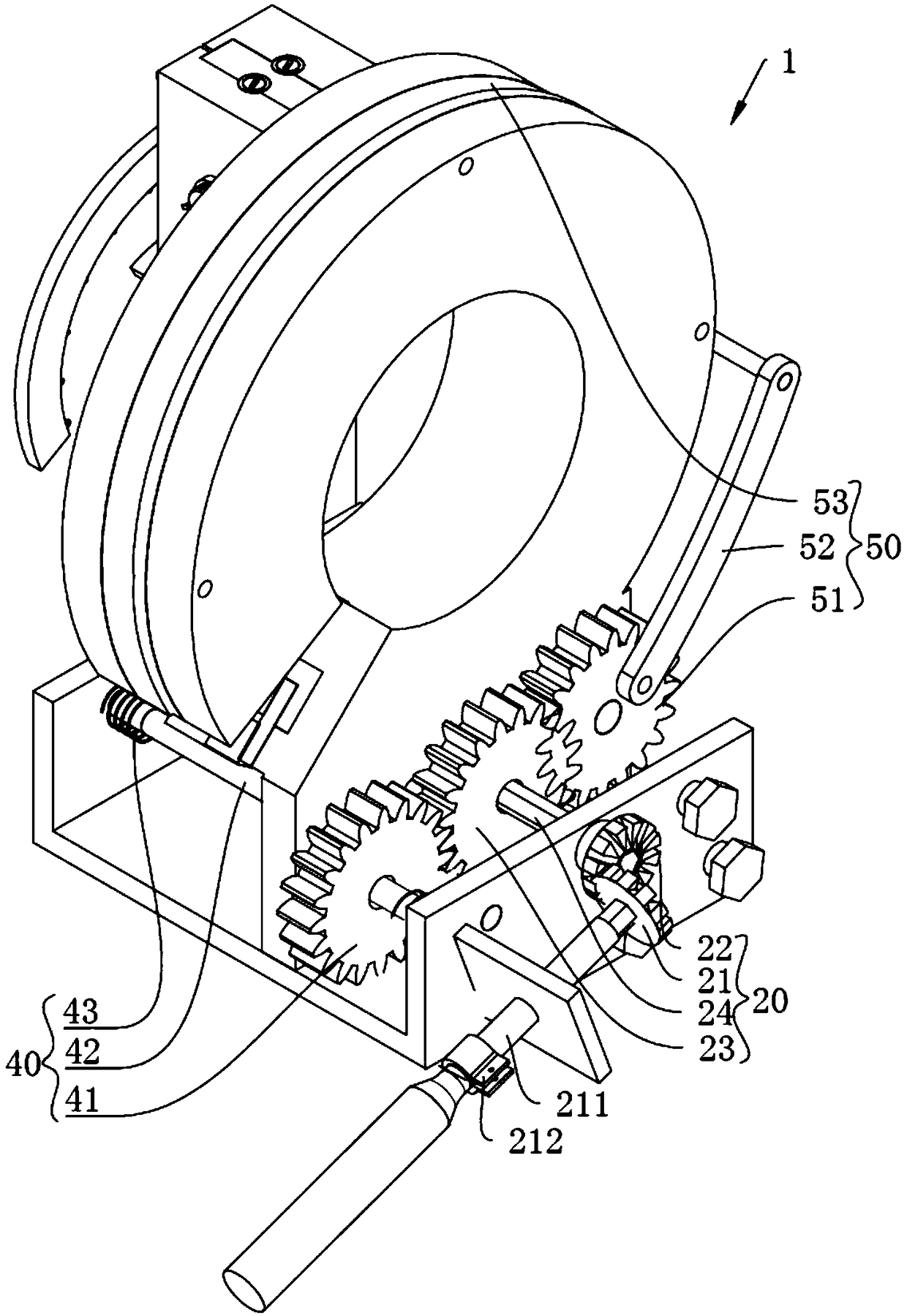

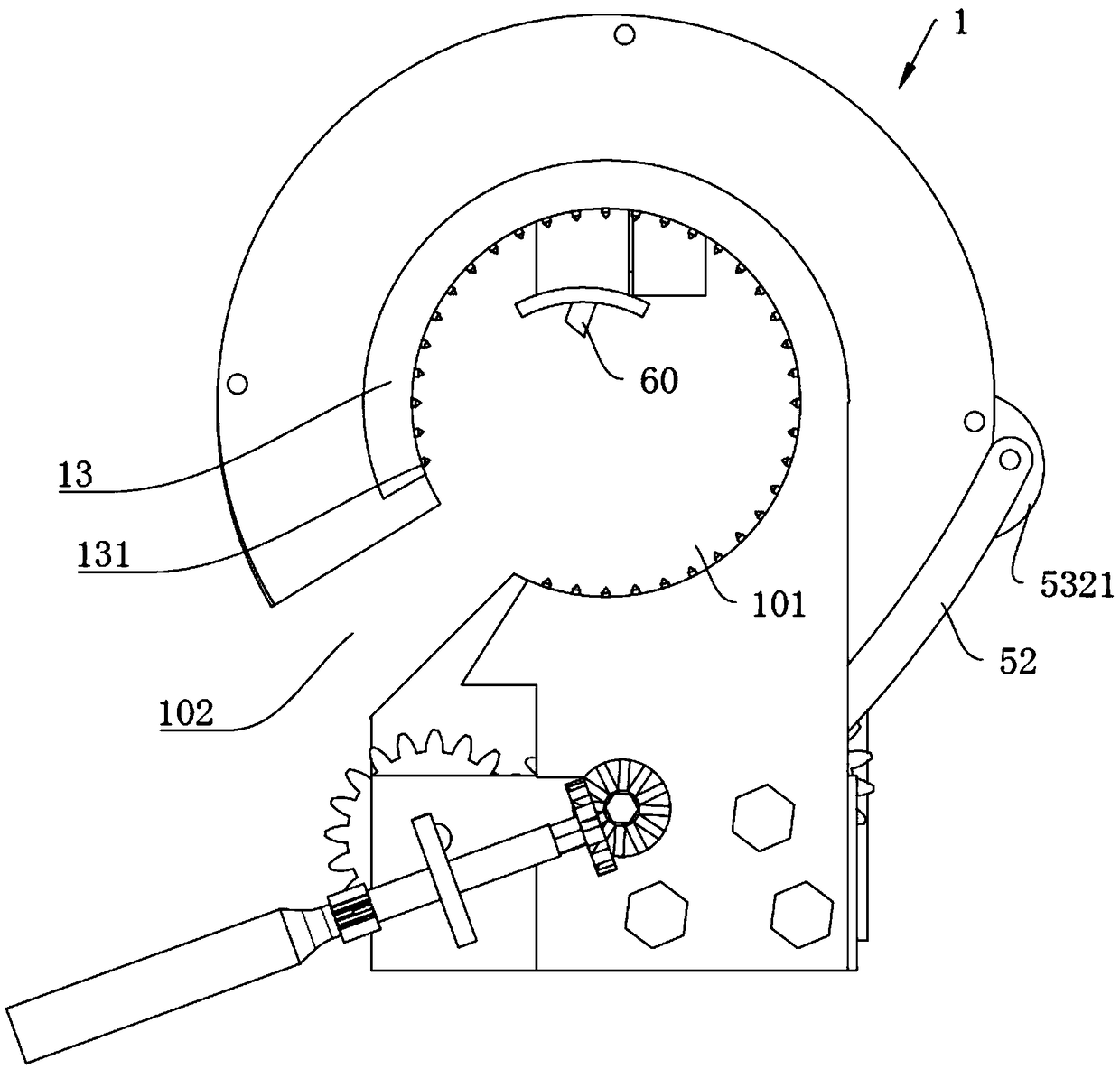

[0056] In this embodiment, the transmission mechanism 20 includes an input member 21 and an output member 22. The insulating rod 30 drives the output member 22 to rotate through the input member 21. When the output member 22 rotates, it simultaneously drives the linear motion assembly 40 to perform linear motion and drives the circular motion assembly 50. Do it in a circular motion.

[0057] As can be seen from the above, the power output by the insulating rod 30 after being transmitted by the transmission mechanism 20 is circular power. It can be understood that the linear motion component 40 is a mechanism that changes circular motion into linear motion, and the circular motion of the circular motion component 50 is a coaxial transmission. A mechanism for circular motion or a mechanism for circular motion driven by parallel shafts.

[0058] The input action of the insulating rod 30 is determined by the structure of the transmission mechanism 20. If the transmission mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com