Electrochemical preparation method of selenium-carbon microspheres and aluminum-selenium battery

An electrochemical and microsphere technology, applied in the field of electrochemistry, can solve the problems of uneven mixing, selenium dissolution, cumbersome process, etc., and achieve the effect of low price and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

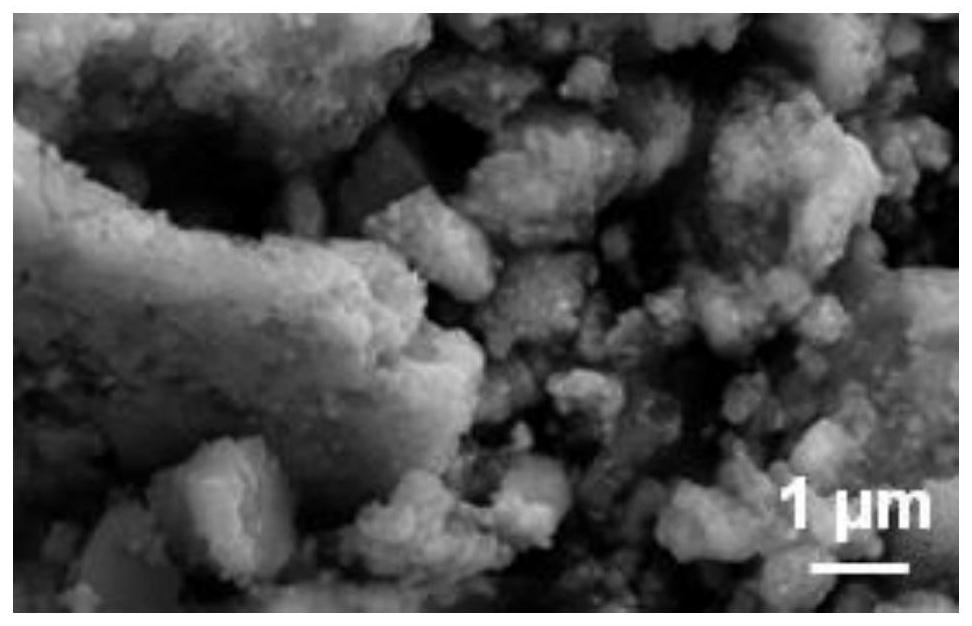

[0027] The selenium dioxide powder was compressed into a columnar block of φ10mm×5mm on a powder molding tablet machine. The selenium dioxide columnar block was used as the cathode, the graphite plate was used as the anode, and the mixed salt of aluminum chloride and sodium chloride with a molar ratio of 1:1 was used as the electrolyte. Under the protection of argon gas, the temperature was raised to 190°C, and electrolysis was carried out at a constant voltage of 0.8V for 120min. After cooling to room temperature, the cathode product was taken out, and after ultrasonic treatment for 10 min, it was repeatedly washed with dilute hydrochloric acid and deionized water for 5 times. The electrolysis product is a selenium-carbon complex, which is in the form of a block. The electron microscope photos are as follows. figure 1 shown. Among them, the mass of selenium accounts for 97.3%, and the proportion of carbon is 2.7%.

Embodiment 2

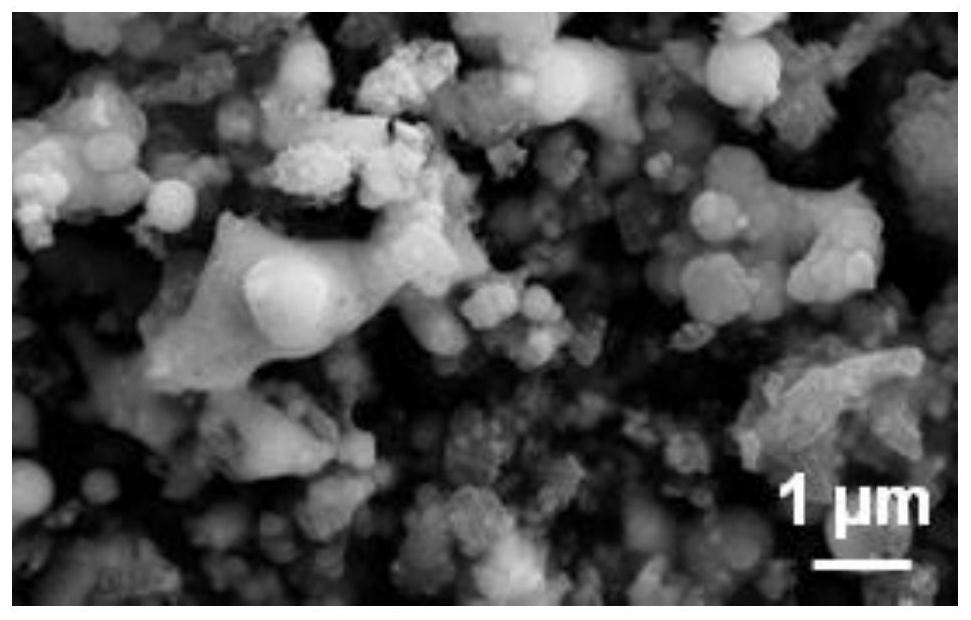

[0029] The selenium dioxide powder was compressed into a columnar block of φ10mm×5mm on a powder molding tablet machine. The selenium dioxide columnar block was used as the cathode, the graphite plate was used as the anode, and the mixed salt of aluminum chloride and sodium chloride with a molar ratio of 1:1 was used as the electrolyte. Under the protection of argon, the temperature was raised to 190 °C, and electrolysis was carried out at a constant voltage of 1.0 V for 120 min. After cooling to room temperature, the cathode product was taken out, and after ultrasonic treatment for 10 min, it was repeatedly washed with dilute hydrochloric acid and deionized water for 5 times. The electrolysis product is a selenium-carbon composite, part of which is in the form of microspheres. The electron microscope photos are as follows: figure 2 shown. Among them, the mass of selenium accounts for 95.5%, and the proportion of carbon is 4.5%.

Embodiment 3

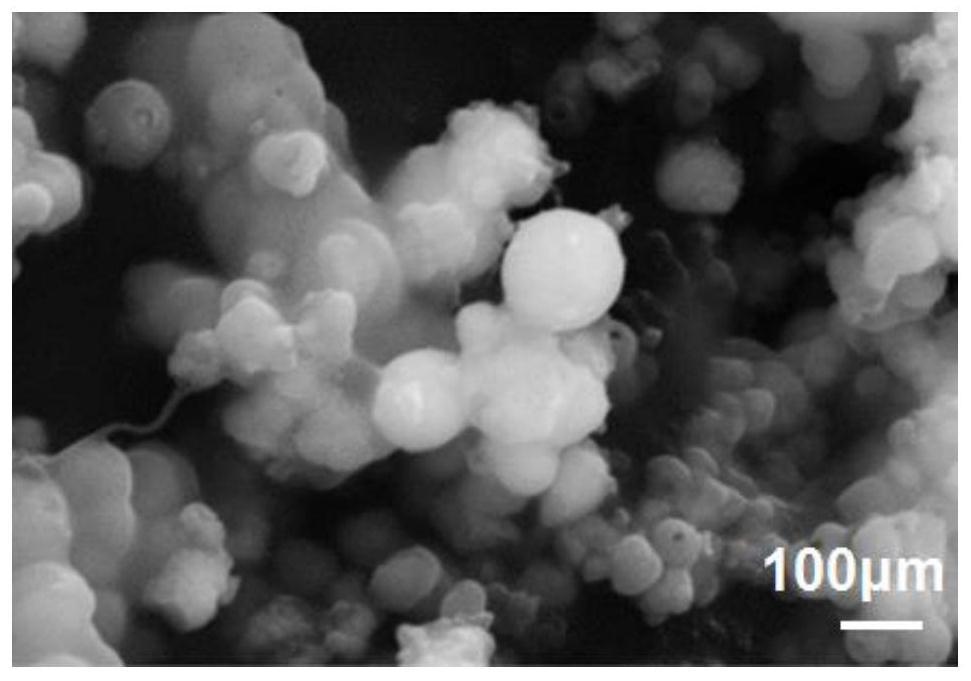

[0031] The selenium dioxide powder was compressed into a columnar block of φ10mm×5mm on a powder molding tablet machine. The selenium dioxide columnar block was used as the cathode, the graphite plate was used as the anode, and the mixed salt of aluminum chloride and sodium chloride with a molar ratio of 1:1 was used as the electrolyte. Under the protection of argon gas, the temperature was raised to 190°C, and electrolysis was carried out at a constant voltage of 1.2V for 120min. After cooling to room temperature, the cathode product was taken out, and after ultrasonic treatment for 10 min, it was repeatedly washed with dilute hydrochloric acid and deionized water for 5 times. The electrolysis product is a selenium-carbon composite, which is completely in the form of microspheres with a diameter of about 100 μm. The electron microscope photos are as follows figure 1 shown. X-ray diffraction patterns such as Figure 4 shown, consistent with the hexagonal selenium lattice. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com