Multifunctional full-automatic rapid wire-stripping machine

A fully automatic and multi-functional technology, applied in the direction of dismantling/armouring cable equipment, etc., can solve the problems of easy damage to cables, inability to set, laborious production efficiency, etc., to ensure cutting quality, ensure cutting accuracy, and improve work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment, and with reference to accompanying drawing, the present invention will be further described:

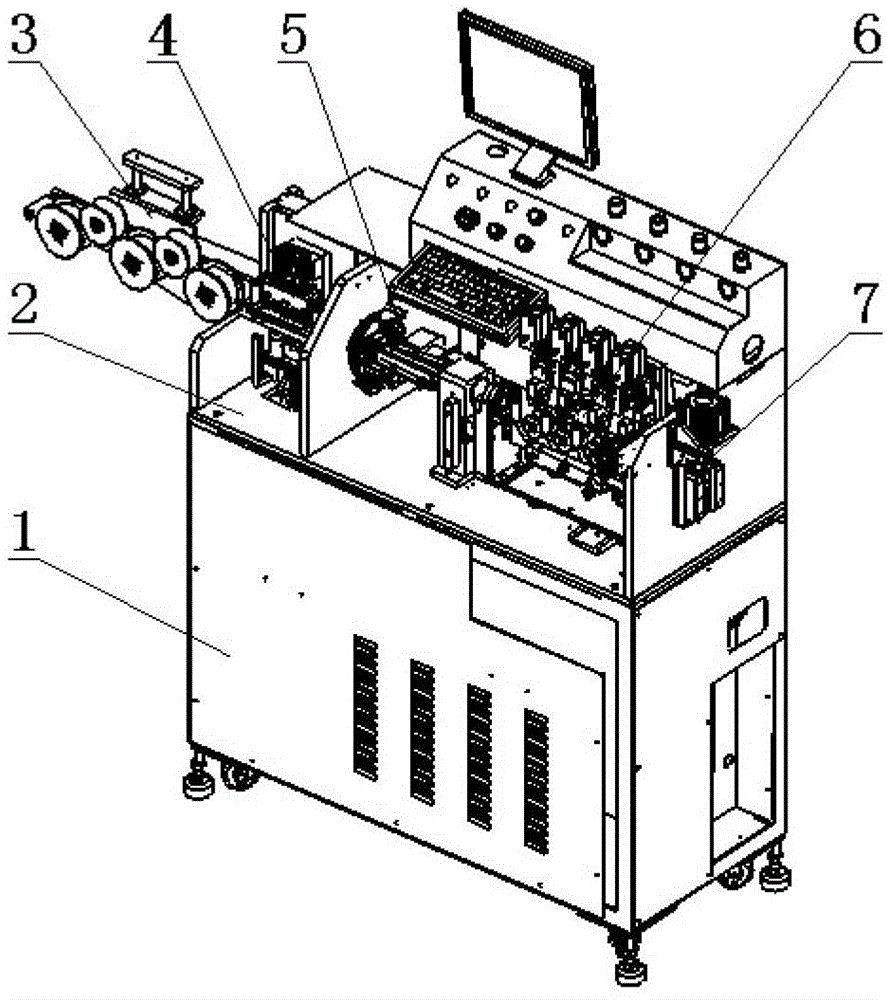

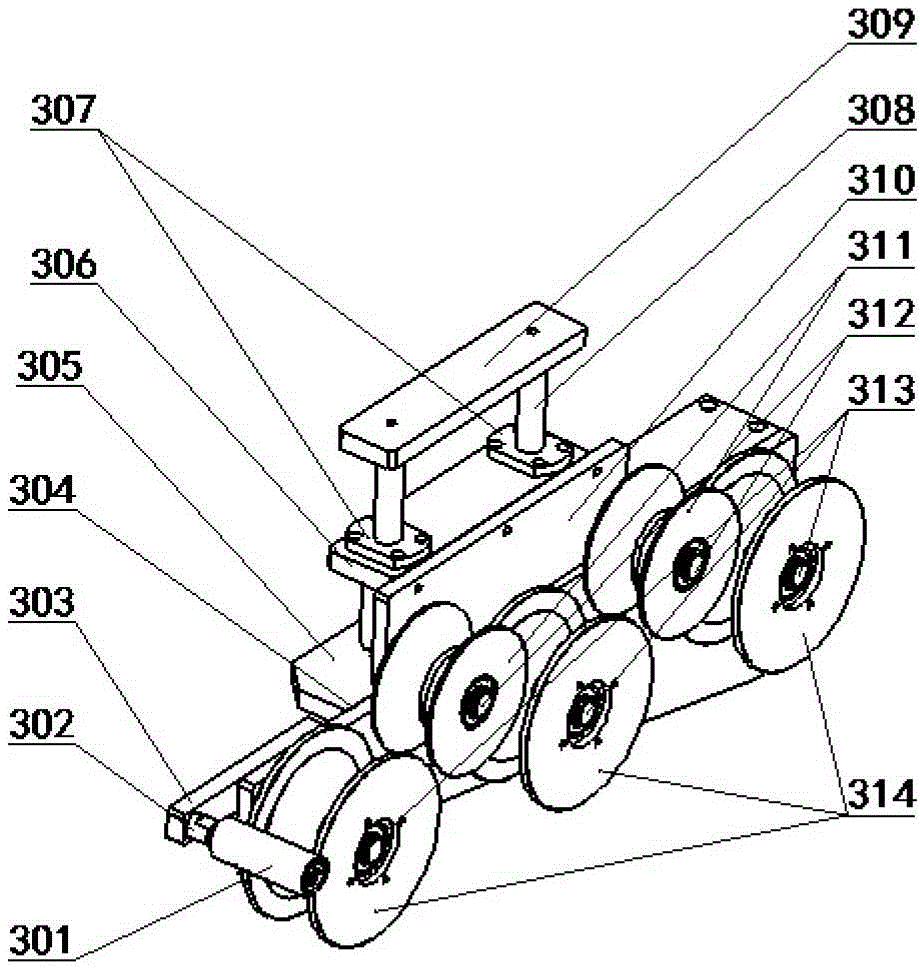

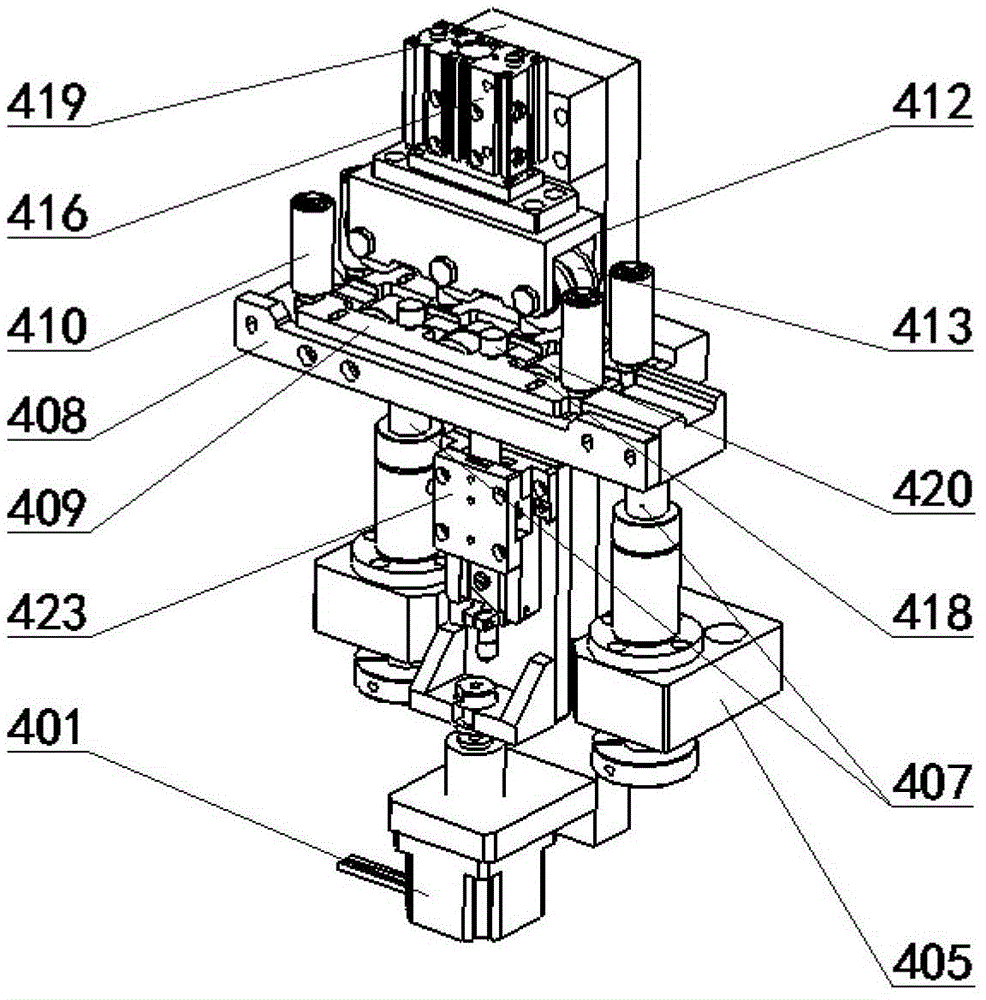

[0021] Such as figure 1 The multi-functional full-automatic fast wire stripping machine of the present invention shown, it comprises frame 1, is installed on described frame work base plate 2, on described work base plate from left to right along the cable movement direction successively There are fixed feeding guide mechanism 3, cross cutting and stripping mechanism 4, ring cutting and stripping mechanism 5, traction mechanism 6 and cutting mechanism 7, such as figure 2 As shown, the feeding guide mechanism includes a front guide wheel mounting plate 304 fixed on the working base plate, on which a plurality of guiding lower roller rods 313 whose axes are arranged along the horizontal direction are installed on the front guide wheel mounting plate 304, Each guiding lower supporting roller rod 313 is sleeved with guiding lower su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com