Pretreatment method and pretreatment system for diamond wire saw core wire

A diamond wire saw and pretreatment technology, which is applied in the direction of metal sawing equipment, tool trimming of sawing machine devices, metal processing equipment, etc., can solve the problem of not being able to effectively increase the adhesion of resin adhesives on the core wire, etc., to achieve The effect of reducing broken wires, reducing waste, and ensuring cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

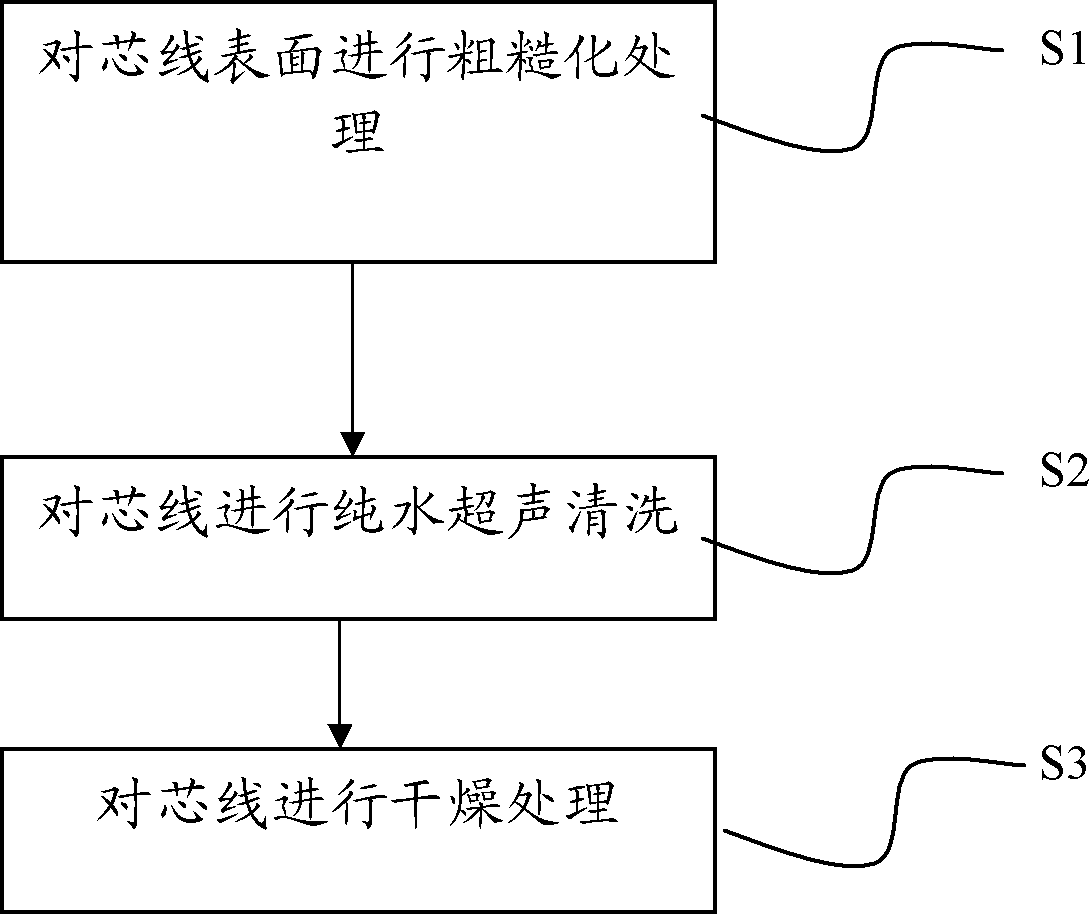

[0043] refer to figure 1 , figure 1 It is a schematic flowchart of a diamond wire saw core wire pretreatment method provided by an embodiment of the present invention, and the method includes steps:

[0044] Step S1: Roughening the surface of the core wire.

[0045] There are two ways to roughen the surface of the core wire: one is to use a grinding roller to grind the surface of the core wire; the other is to use an acid solution to corrode the surface of the core wire.

[0046] For the first case, you can wrap sandpaper on the surface of the grinding roller (the model is, for example, No. 1000), and make the core wire enter between the two grinding rollers along a specific guide wheel, and the two grinding rollers rotate in opposite directions. Moreover, the rotational speed of the grinding roller should be lower than the speed at which the core wire is transmitted along the guide wheel. Specifically, the relative speed of the two can be set to 0.05m / s. After the core wir...

Embodiment 2

[0054] The pretreatment method for roughening the surface of the diamond wire saw core wire is described in detail in the first embodiment. On the basis of the first embodiment, this embodiment combines degreasing and activation treatment for the pretreatment method of the diamond wire saw core wire Describe in detail.

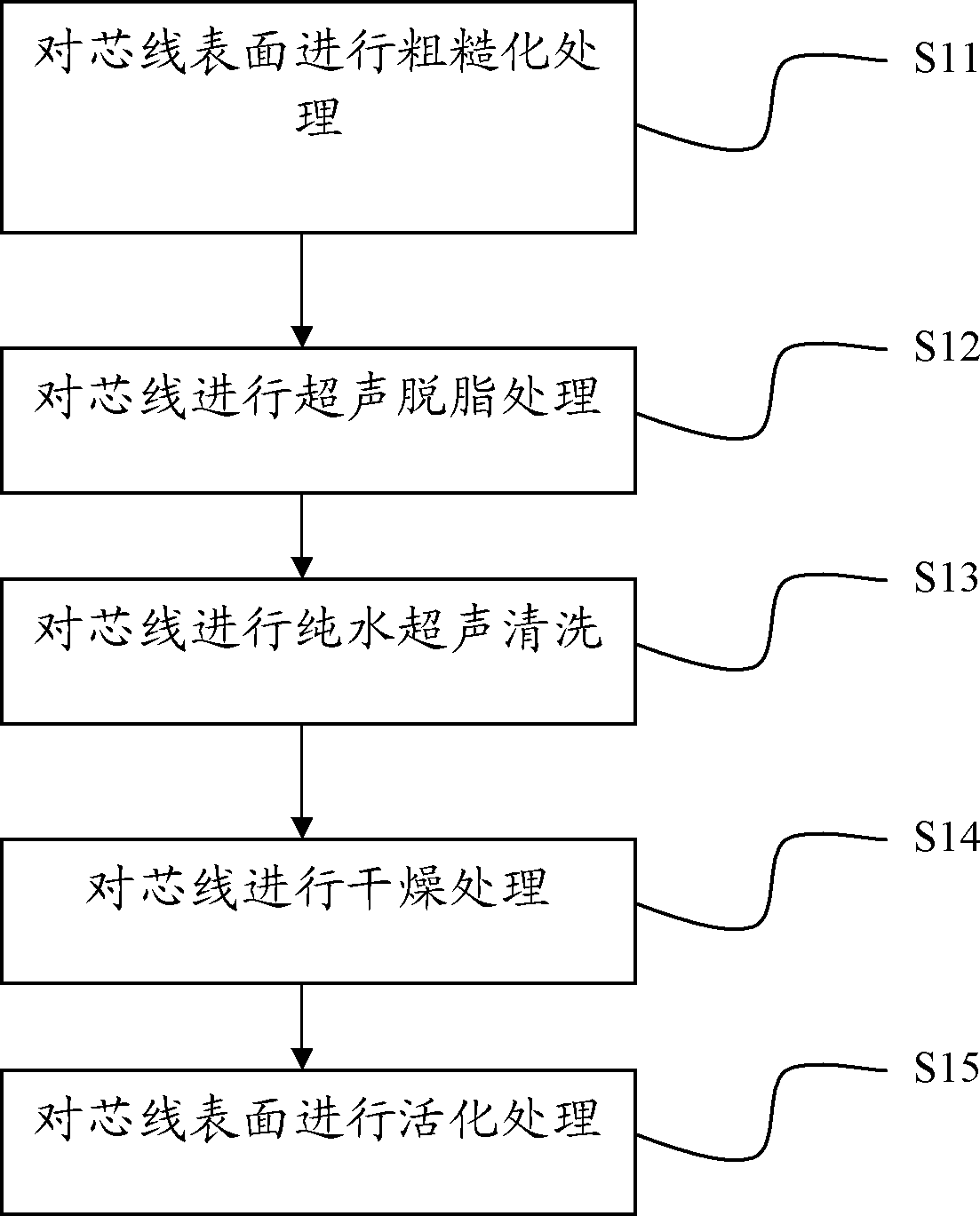

[0055]refer to figure 2 , figure 2 It is a schematic flow chart of another diamond wire saw core wire pretreatment method provided by the embodiment of the present invention. The method includes the following steps:

[0056] Step S11: Roughening the surface of the core wire.

[0057] The surface of the core wire is roughened as described in step S1 in the first embodiment. It should be noted that if the surface of the core wire is roughened by acid, after this step, the surface of the core wire needs to be ultrasonically cleaned with pure water to remove the acid on the surface of the core wire, and then proceed to the next step.

[0058] Step S12: Ultra...

Embodiment 3

[0089] The pretreatment method of the diamond wire saw core wire provided by the present invention has been described in detail above, and the pretreatment system of the diamond wire saw core wire provided by the present invention will be described in detail below.

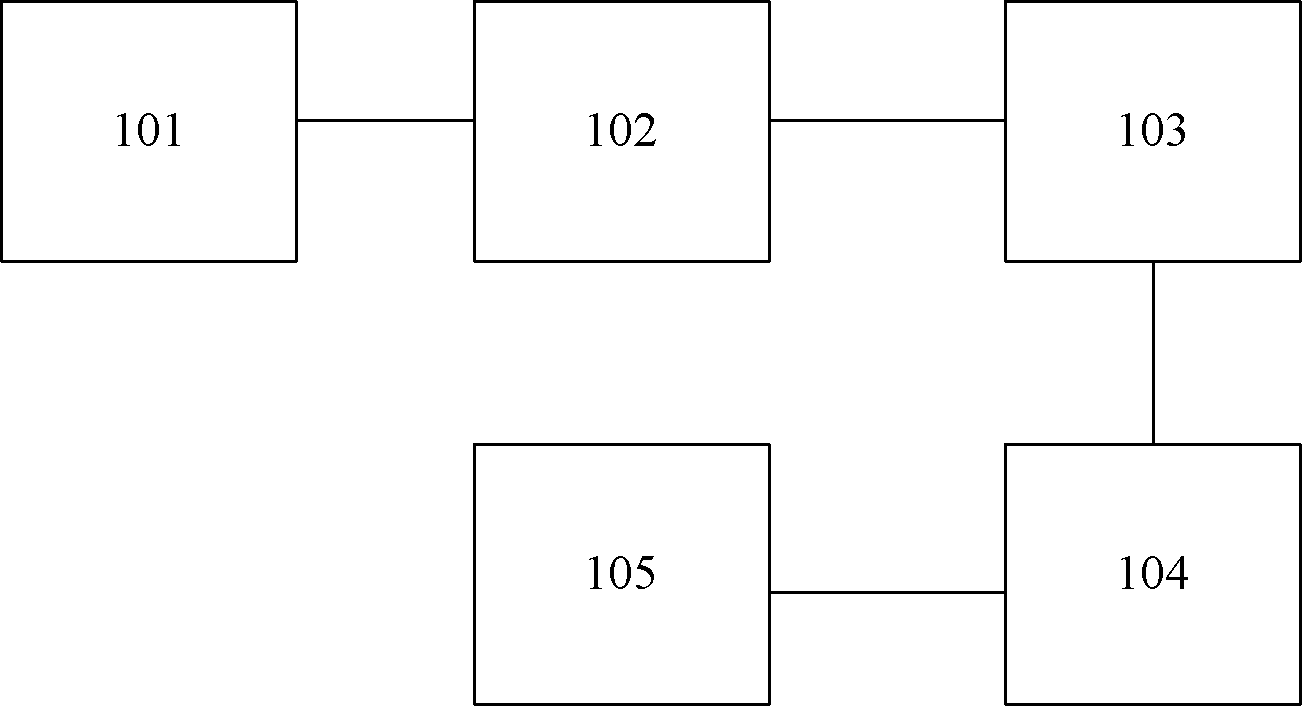

[0090] refer to image 3 , image 3 It is a schematic structural diagram of a pretreatment system for a diamond wire saw core wire provided by the present invention. The pretreatment system includes: a roughening device 101 for roughening the surface of the core wire; for removing metal residues on the surface of the core wire or a degreasing device 102 for grease; a cleaning device 103 for performing pure water ultrasonic cleaning on the roughened core wire; a drying device 104 for drying the cleaned core wire; An activation device 105 for activating the wire surface.

[0091] Wherein, the roughening device 101 can be a grinding roller or an acid corrosion device; the drying device 104 can be a hot air blower; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com