Steering wheel spoke ring pipe cutting clamp

A steering wheel and tube cutting technology, which is applied to manufacturing tools, grinding workpiece supports, grinders, etc., can solve the problems of poor accuracy of the cutting angle of the coiled tube, deviation of the cutting angle of the coiled tube, shaking and displacement of the coiled tube, etc. The effect of pipe cutting accuracy, guaranteeing processing quality and guaranteeing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

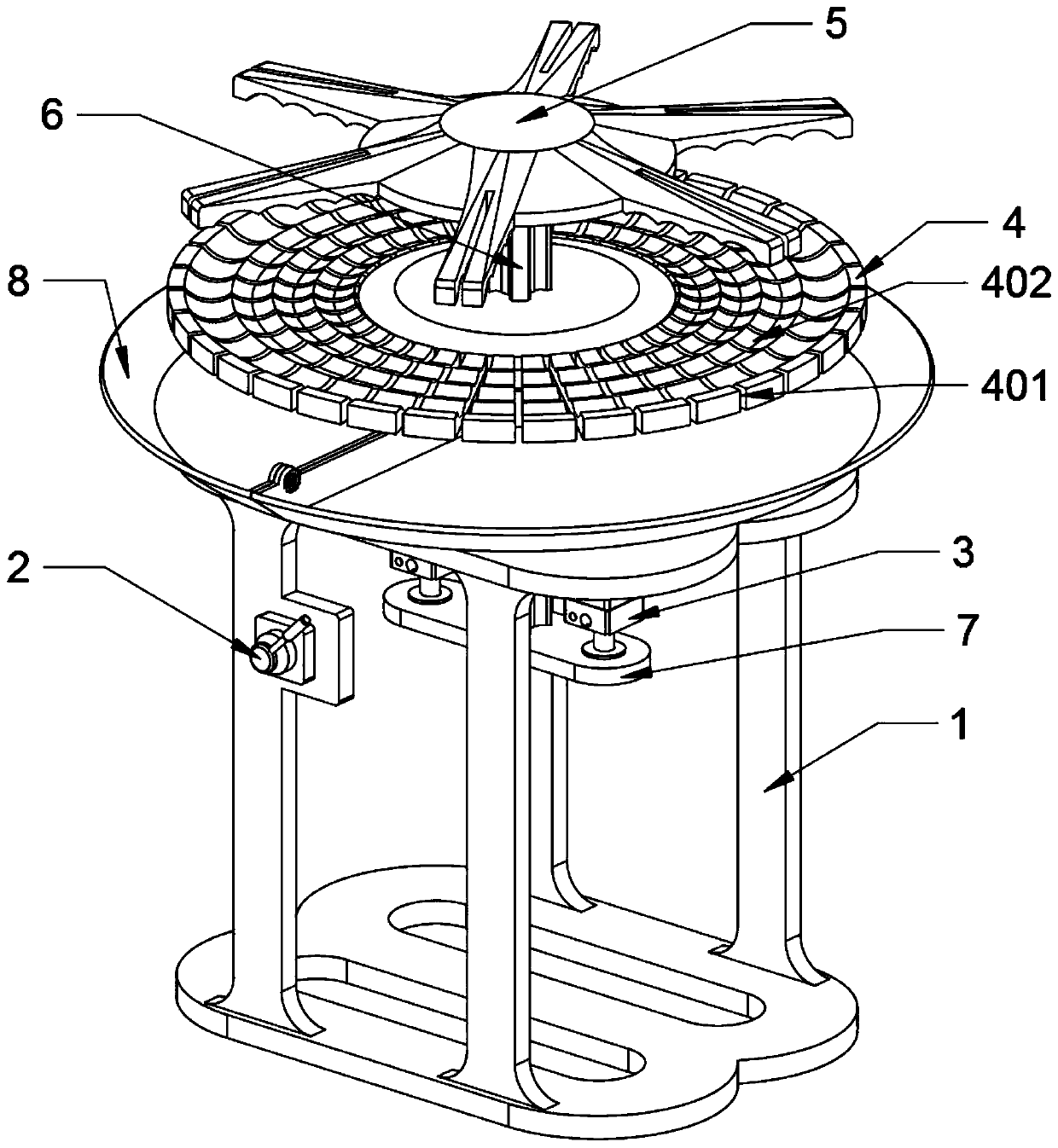

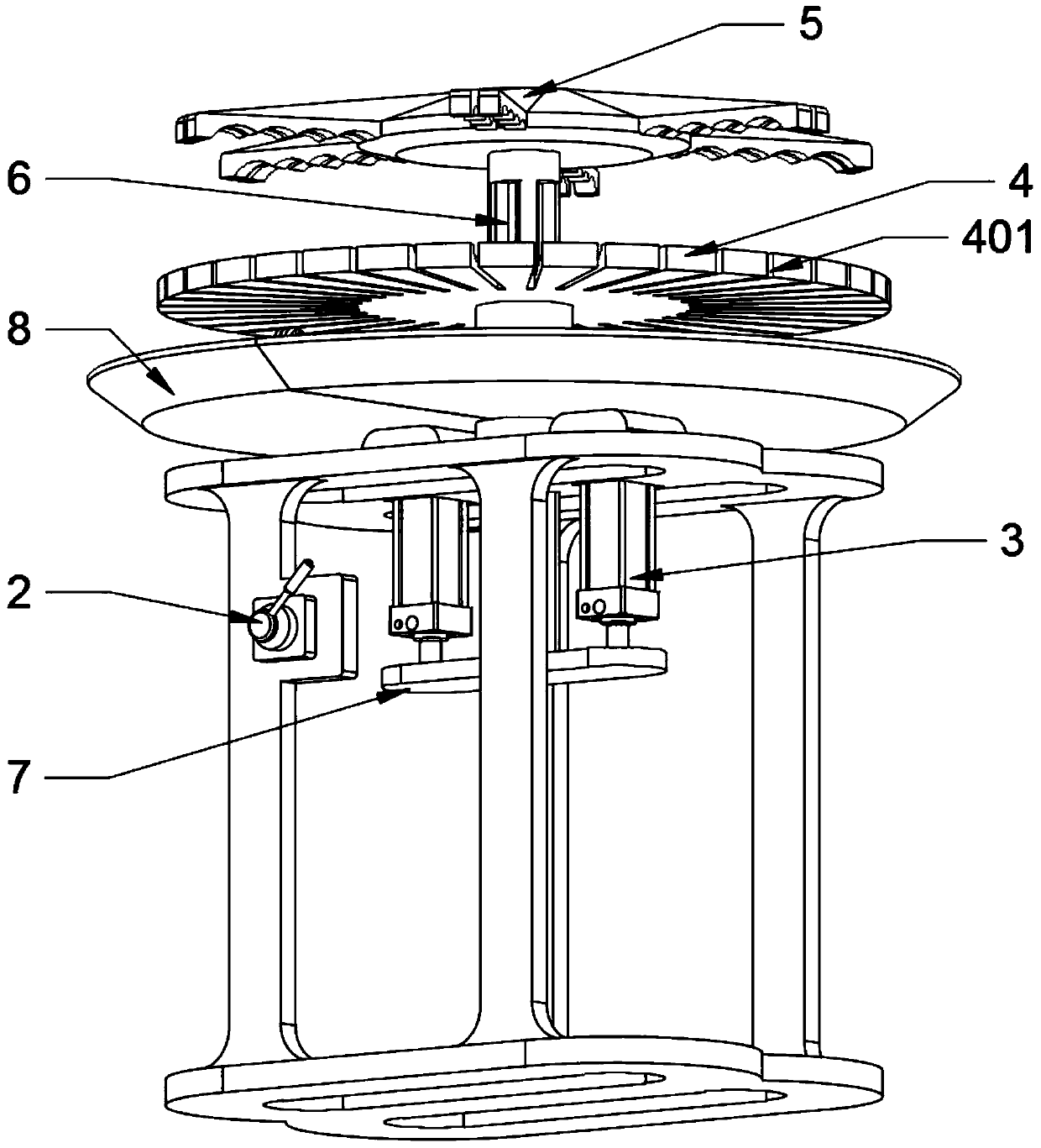

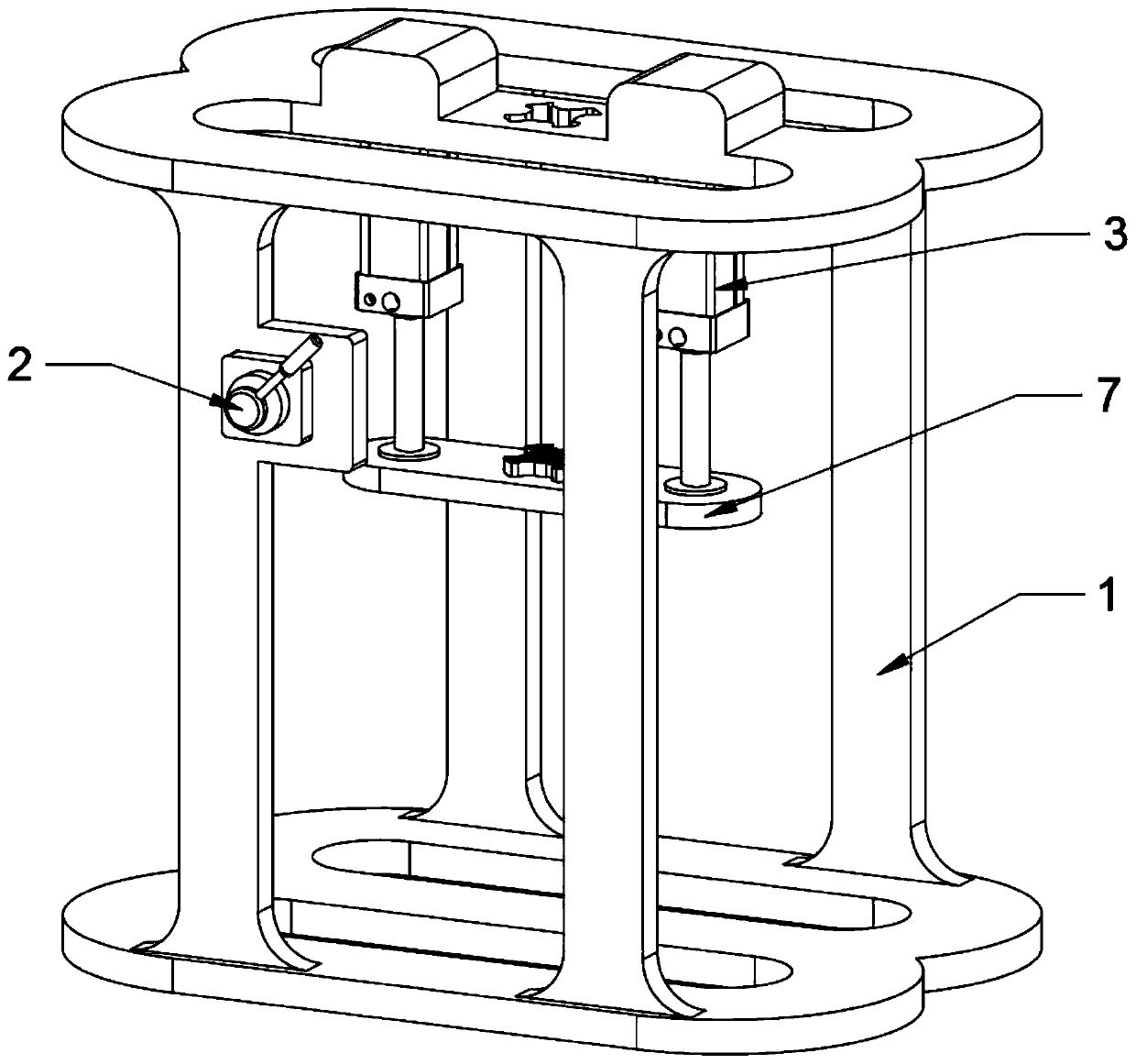

[0026] as attached figure 1 to the attached Image 6 shown:

[0027] The present invention provides a steering wheel spoke pipe cutting fixture, including a support frame 1, a control valve 2, a cylinder 3, a fixed chuck 4, a chuck notch 401, a spoke limiting groove 402, a clamping top frame 5, and an adjusting slide column 6, the receiving plate 7 and the scrap storage tank 8; the support frame 1 is a frame structure, and the control valve 2 is installed on the outer end surface of the support frame 1, and the control valve 2 is connected with the external high-pressure gas supply pipeline; the cylinder 3 There are two places, and the two air cylinders 3 are installed in the top of the support frame 1 in an inverted shape, and the air cylinder 3 is connected with the control valve 2 through the air pipe; the fixed chuck 4 is installed on the top end surface of the support frame 1, and is broken. The material storage tank 8 is placed on the outer side of the top end face of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com