Cutting, edge-grinding and cleaning device for section bar cutting

A cleaning device and cutting device technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of easy deflection, cutting accuracy defects, unstable positioning, etc., to improve quality, ensure cutting accuracy, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below according to the drawings and embodiments.

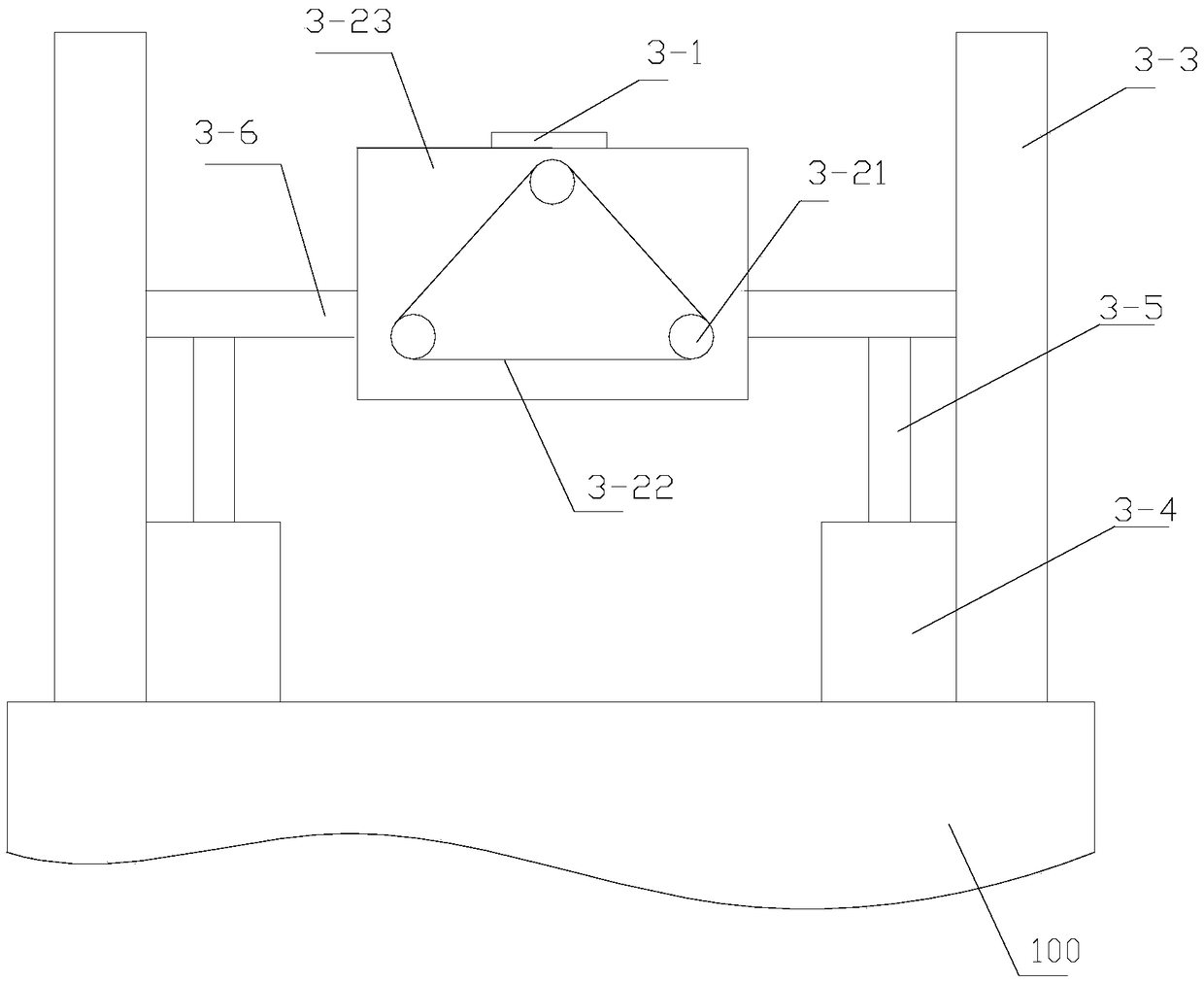

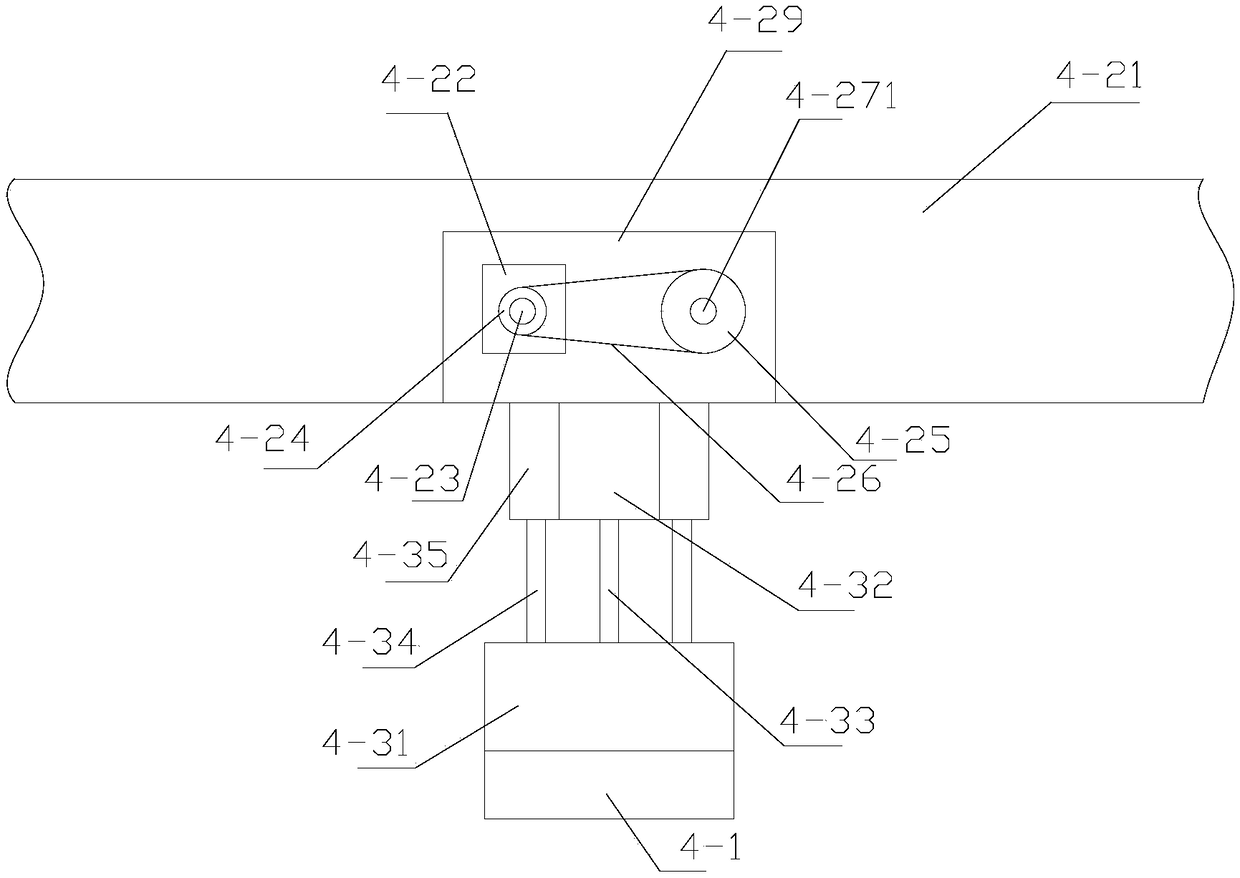

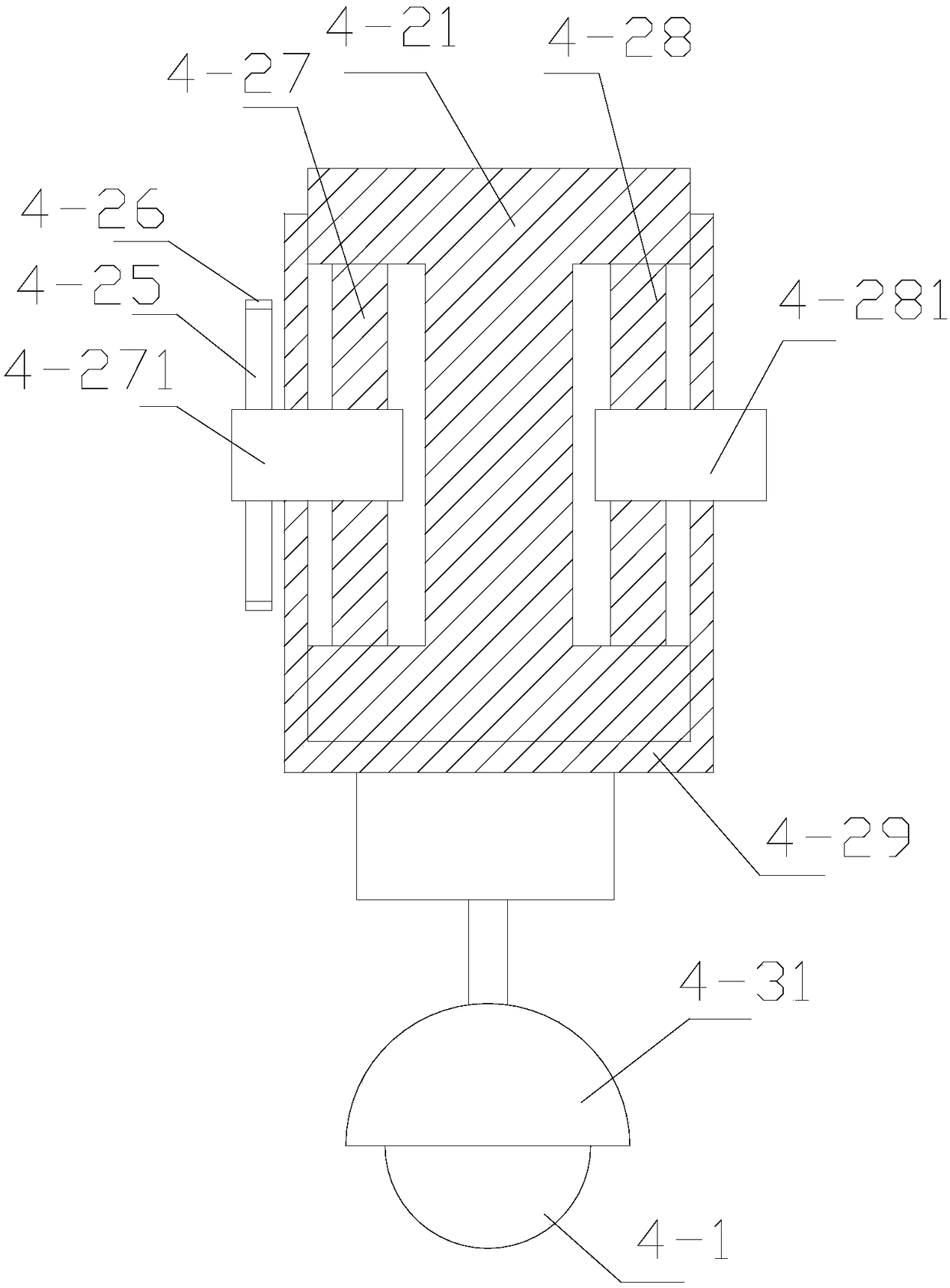

[0027] figure 1 is a formal schematic diagram of the cutting device of the present invention, figure 2 It is a schematic front view of the edging device of the present invention, image 3 It is a side sectional view of the edging device of the present invention, Figure 4 is a formal schematic diagram of the cleaning device of the present invention, Figure 5 It is a schematic side view of the cleaning device of the present invention, referring to Figure 1-Figure 5 According to the present invention, the cutting and edging cleaning device for profile cutting includes: an operating platform 100, a cutting device, an edging device, and a cleaning device.

[0028] The cutting device includes a cutting drive mechanism 3-1, a cutting lifting mechanism, three cutting drums 3-21, a cutting line 3-22, and a cutting fixing plate 3-23. The above-mentioned cutting fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com