Equipment and method for preparing environment-friendly EPE foaming packaging material

A packaging material and environmental protection technology, applied in metal processing and other directions, can solve the problems of difficult cutting of materials into irregular shapes, burrs easily generated in the incision of materials, and increased labor costs, so as to increase processing accuracy and save manpower and labor. Cost, effect of increased functionality and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

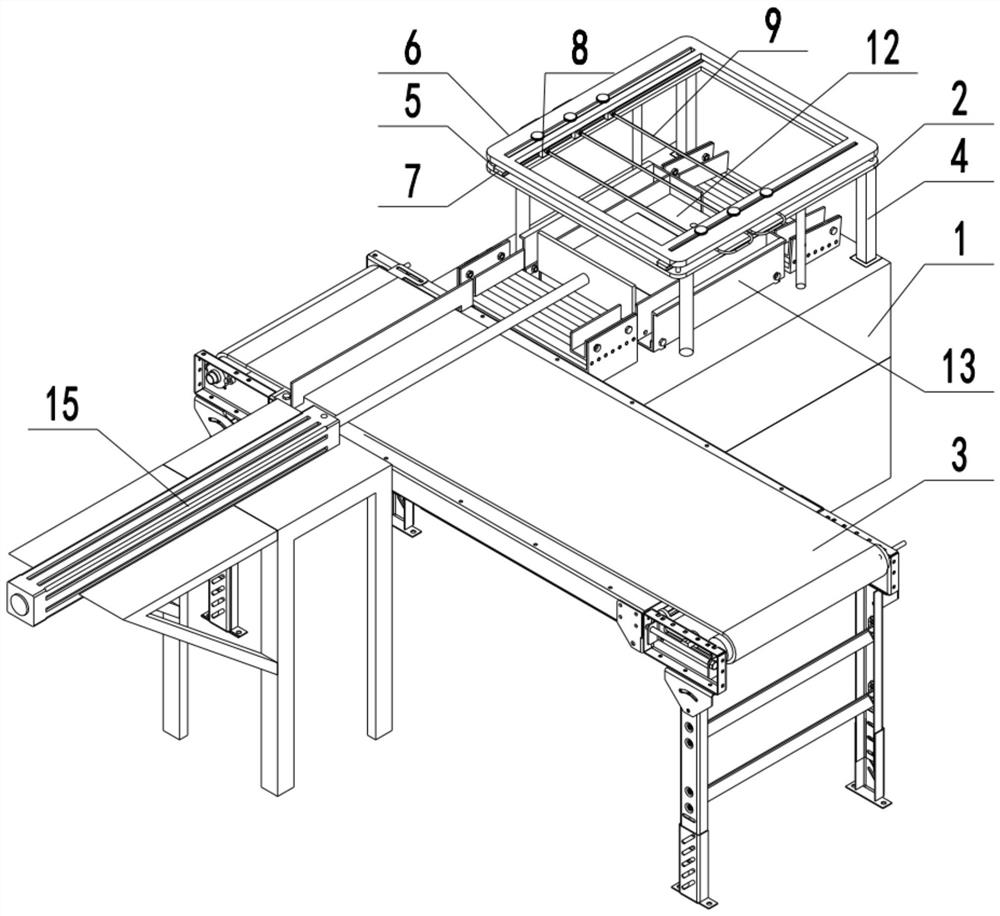

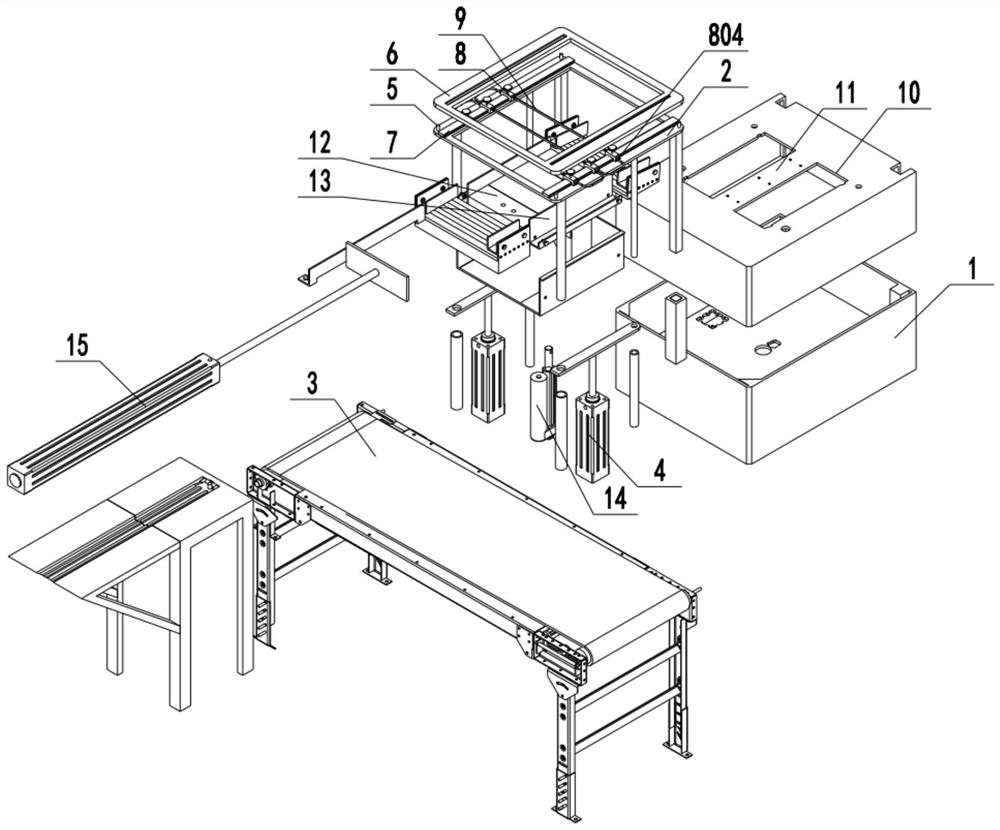

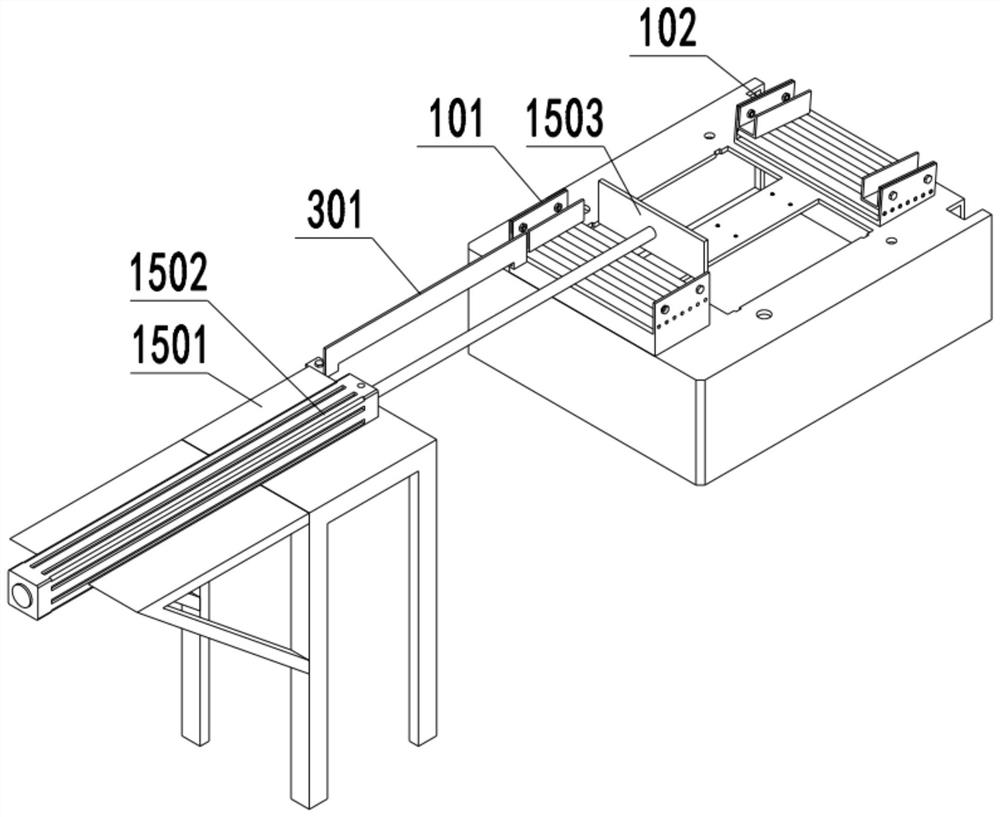

[0038] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0039] Such as Figure 1-2As shown, an environment-friendly EPE foam packaging material preparation equipment and method proposed by an embodiment of the present invention includes a support frame 1, an installation frame 2 and a conveyor belt 3, and the installation frame 2 is vertically slid on the support frame 1 by pushing the component 4 On the installation frame 2, the connection frame 6 arranged parallelly above it is fixedly connected through the connection column 5, and both sides of the upper surface of the installation frame 2 are fixedly connected with the slide rail 7 along the length direction, and the slide rail 7 is slidably installed with multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com