Cable end sheath stripping method and device

A technology of peeling off the outer skin and the cable end, applied in the direction of disassembling/armoring cable equipment, etc., can solve the problems of low efficiency, high production cost, poor production flexibility, etc., and achieve the effect of simple overall structure, low processing cost, and large processing flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

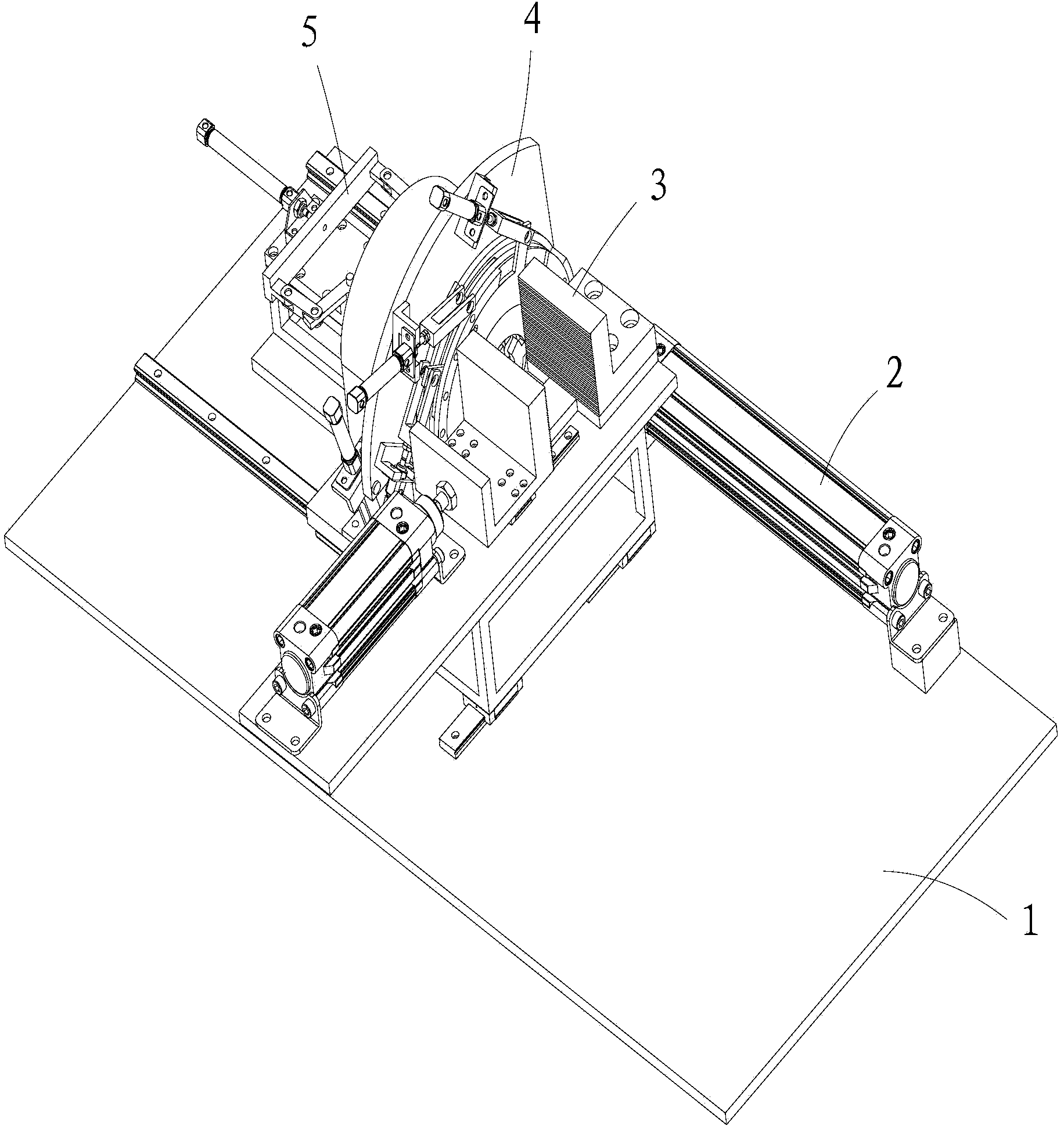

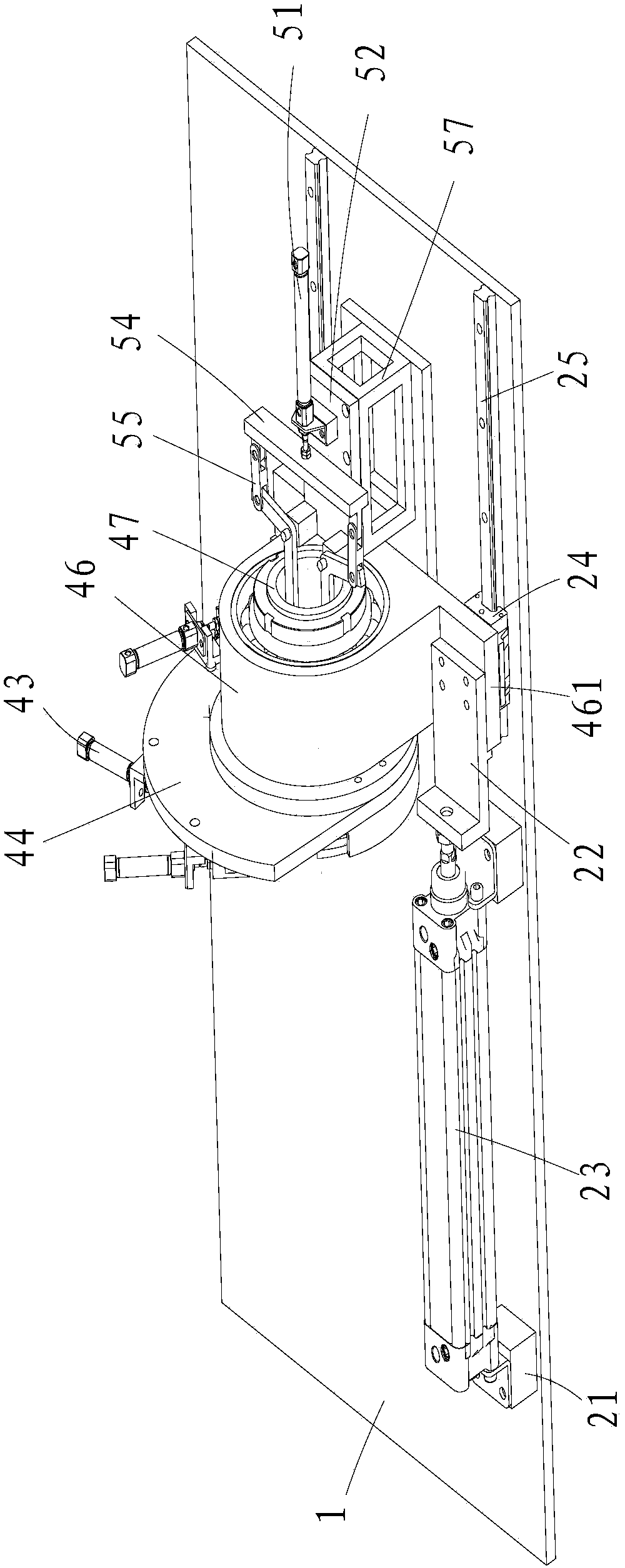

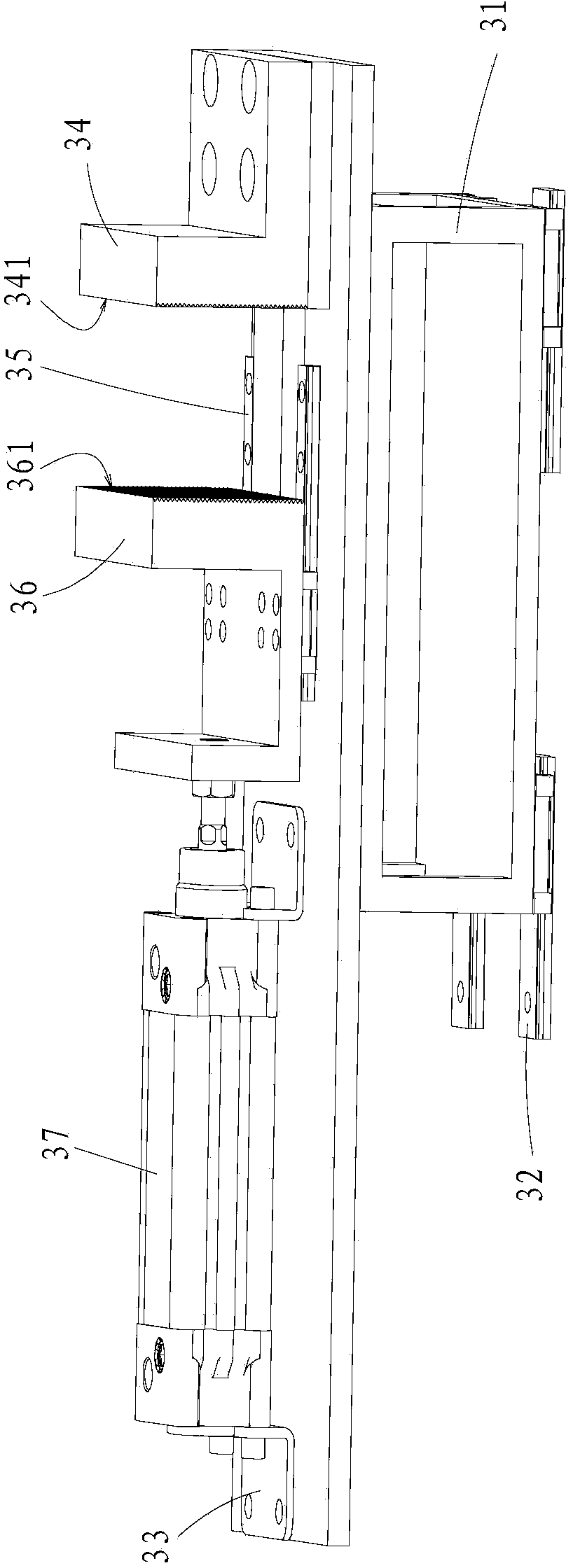

[0031] The present invention firstly provides a method for stripping the sheath of the cable end, which is to clamp the two ends of the cable to be stripped with clamping parts to realize the fixing of the cable and prevent the cable from rotating. Set multiple sets of different blades, through the radial feed of the blades, first the blades cut into a certain depth of the outer skin, and use the force sensor to adjust and control the cutting status of the blades and the cable to avoid cutting too shallow or into the core wire, and then by The driving mechanism drives the blade to rotate to form an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com