Power cable recycling and stripping device

A power cable and cable technology, which is applied to cable installation devices, cable installation, and equipment for dismantling/armored cables, etc., can solve the problem that the cutting depth of the cable sheath cannot be adjusted flexibly and quickly, and the cable peeling effect is reduced. and other problems, to achieve the effect of efficient stripping process and adaptability to large cable sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

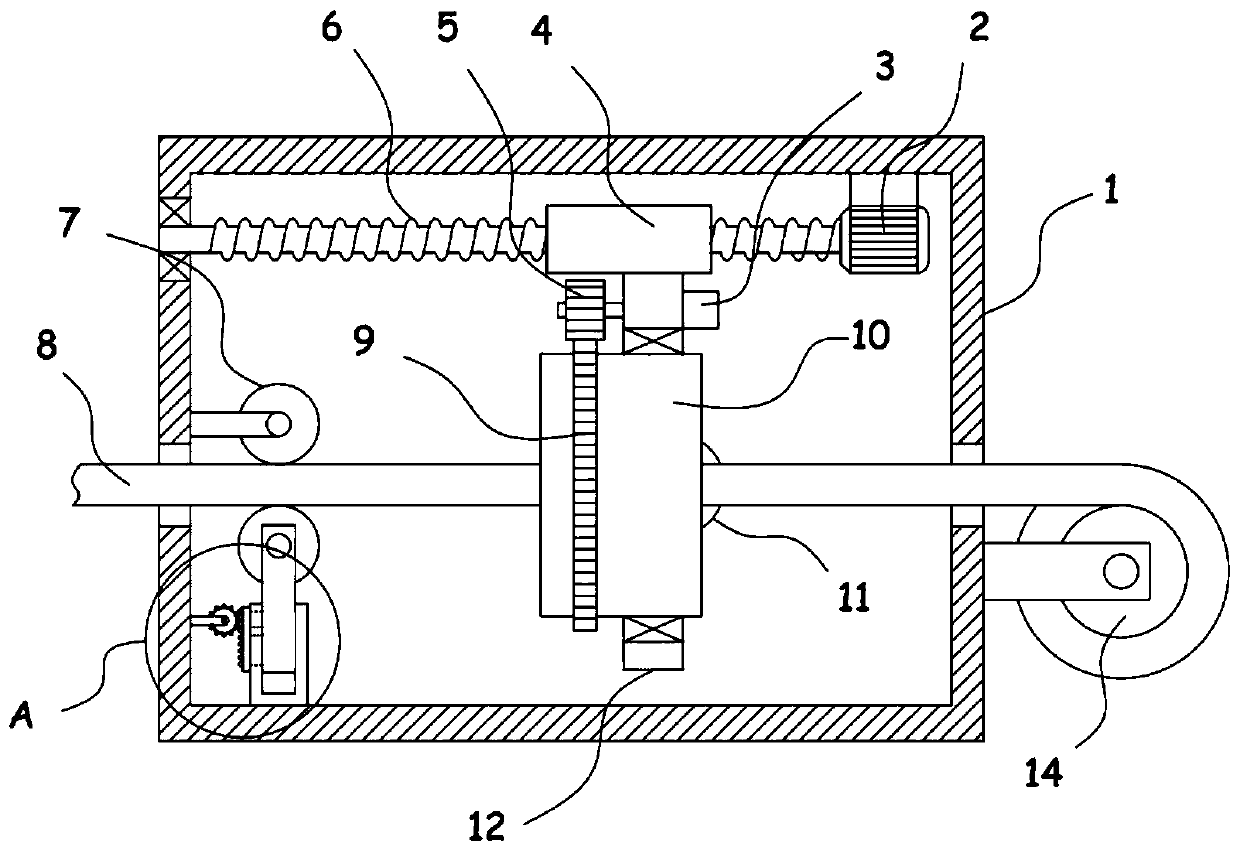

[0023] see Figure 1-4 , a power cable recovery stripping device, including a support frame 1, the top of the support frame 1 is fixed with a servo motor I2, the support frame 1 is provided with a ring cutting mechanism for peeling the cable 8, and the servo motor I2 is driven and connected There is a translation mechanism including a threaded sleeve 4 for driving the circumcision mechanism to move laterally, and the support frame 1 is provided with a conveying mechanism for conveying the sheath of the cable 8 .

[0024] When peeling the cable 8, the cable 8 is first passed through the ring cutting mechanism, and then the outer skin of the cable 8 is cut through the ring cutting mechanism to realize the cutting of the outer skin of the cable 8, and the ring cutting is driven by the translation mechanism The lateral movement of the mechanism draws the sheath off the main body of the cable 8 .

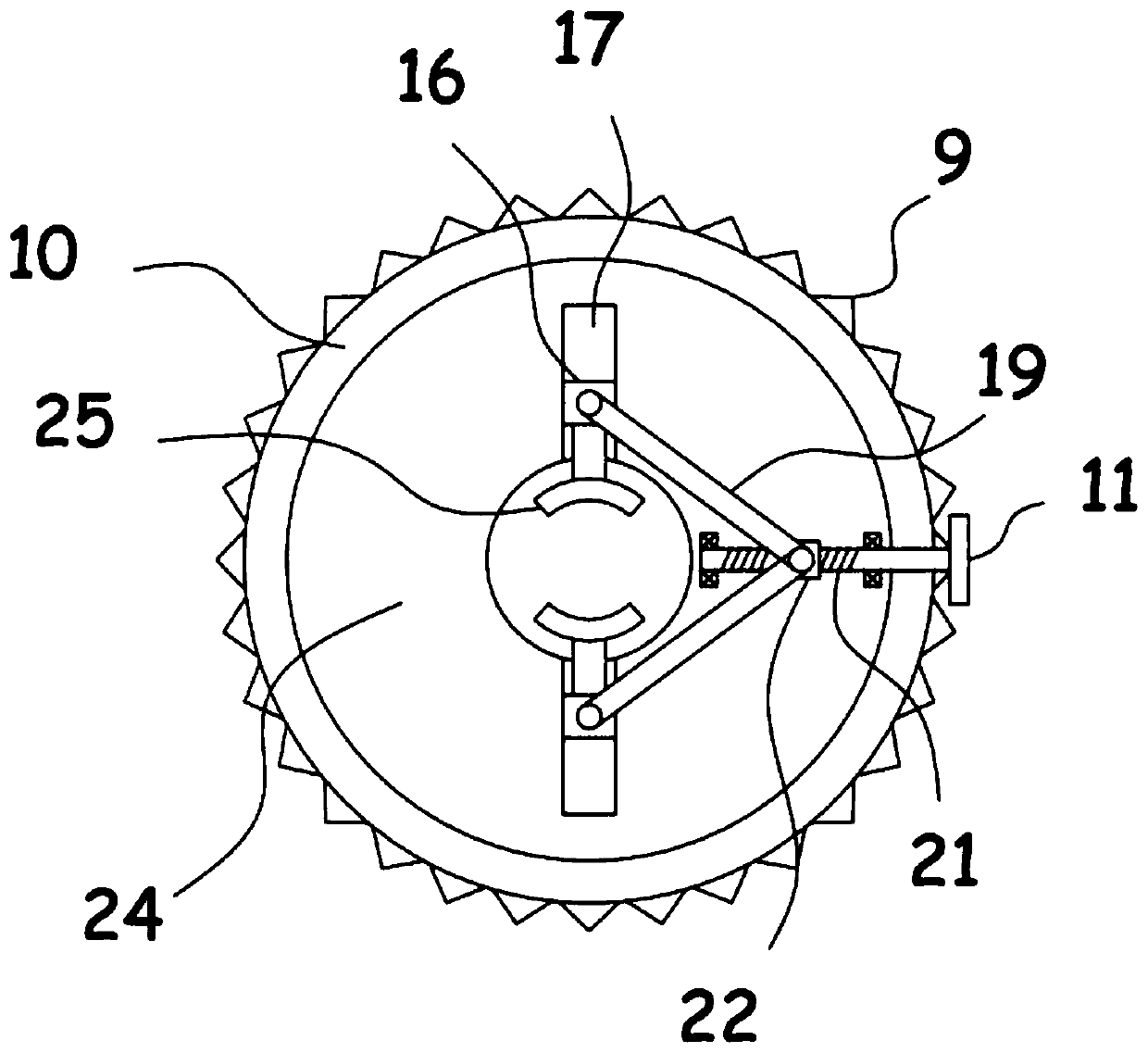

[0025] Specifically, the ring cutting mechanism includes a sleeve plate 24 sleeved ...

Embodiment 2

[0030] On the basis of Embodiment 1, in order to facilitate the separation of the cut cable 8 sheath from its main body, this device is also provided with a translation mechanism, which includes coaxially fixed with the output shaft of the servo motor I2 and connected with the threaded sleeve 4 The threaded rod 6 adapted to the thread drives and rotates the threaded rod 6 through the servo motor I2, and the threaded rod 6 drives the threaded sleeve 4 threadedly connected with it to move laterally, thereby realizing the lateral movement of the arc-shaped blade 25 relative to the cable 8 , to realize pulling the sheath off the cable 8 .

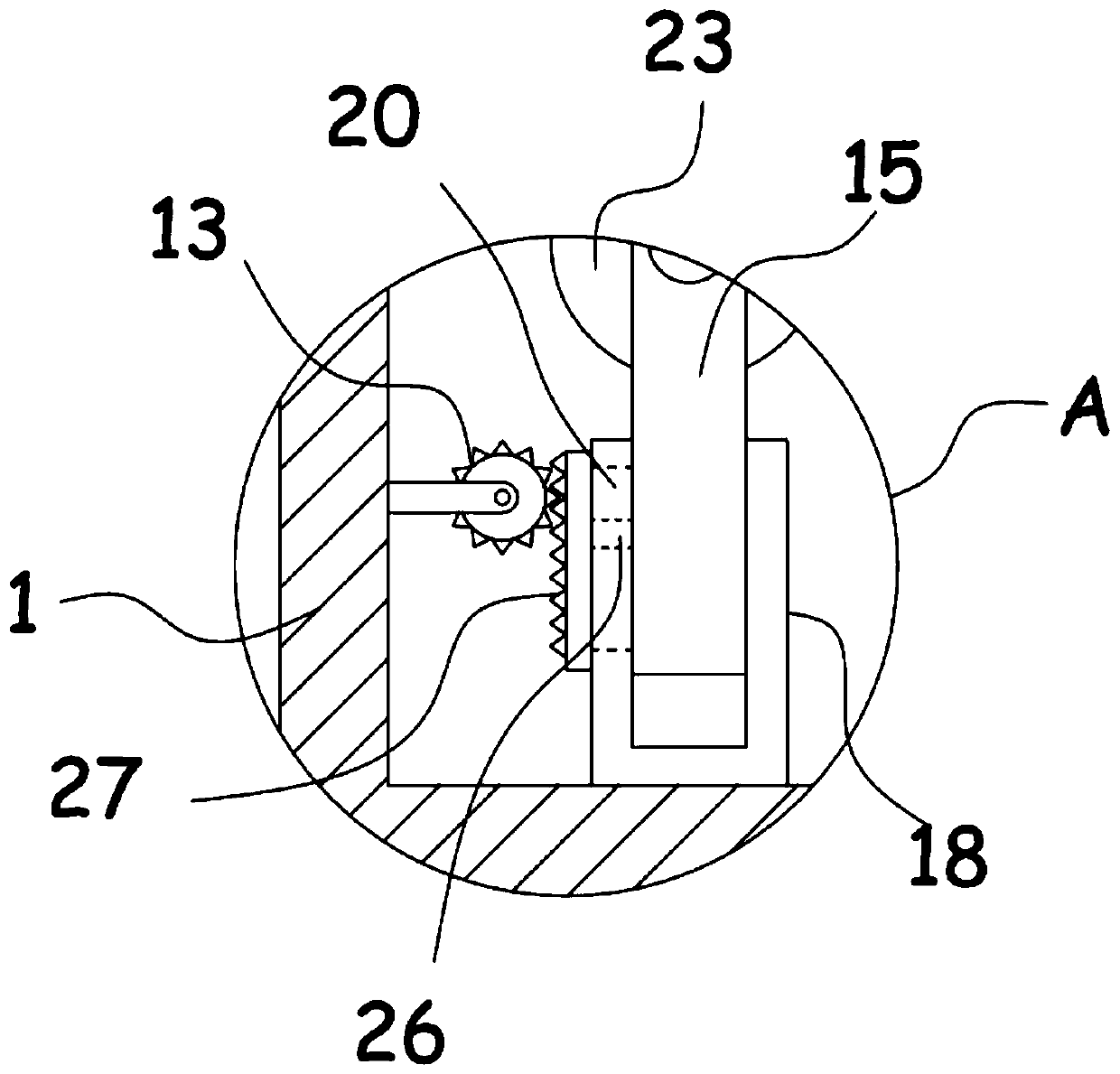

[0031] In order to extract the outer skin from the cable 8 better, the device is also provided with a conveying mechanism, which specifically includes a guide cylinder 18 fixed on the support frame 1, on which the guide cylinder 18 is slidably installed with a sliding frame 15, and the sliding frame 15 rotates A lower pressing roller 23 abuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com