Automatic wire winding, binding and cutting integrated machine and automatic winding, binding and cutting method thereof

An all-in-one machine and wire technology, which is applied in the fields of bundling machine parts, conveying filamentous materials, packaging, etc., can solve the problems of low degree of automation, affecting product quality, and high labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

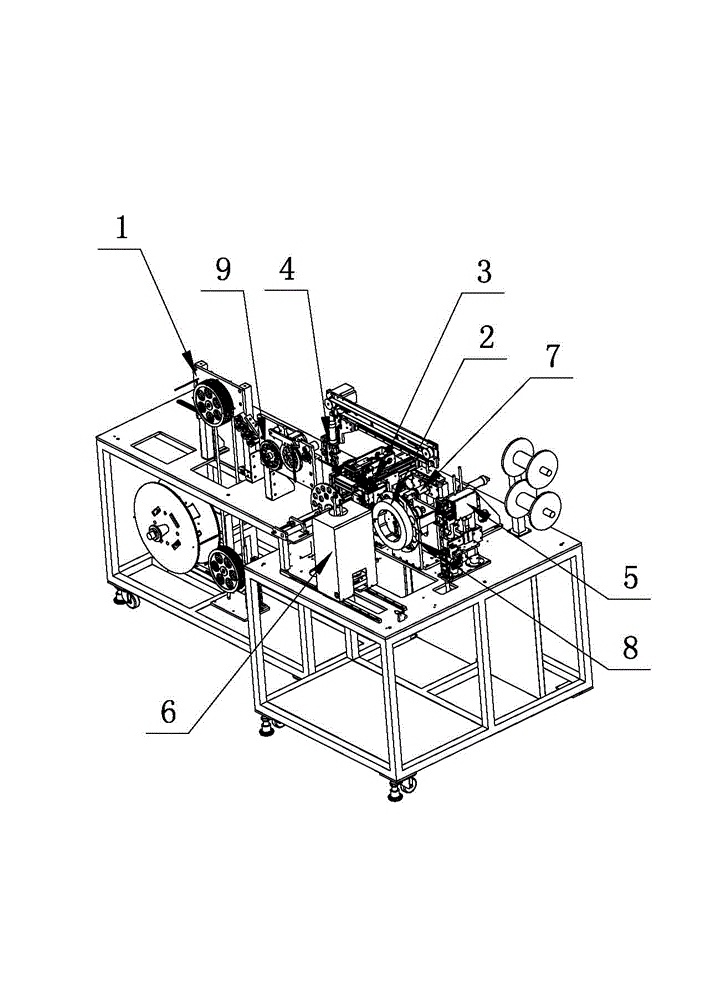

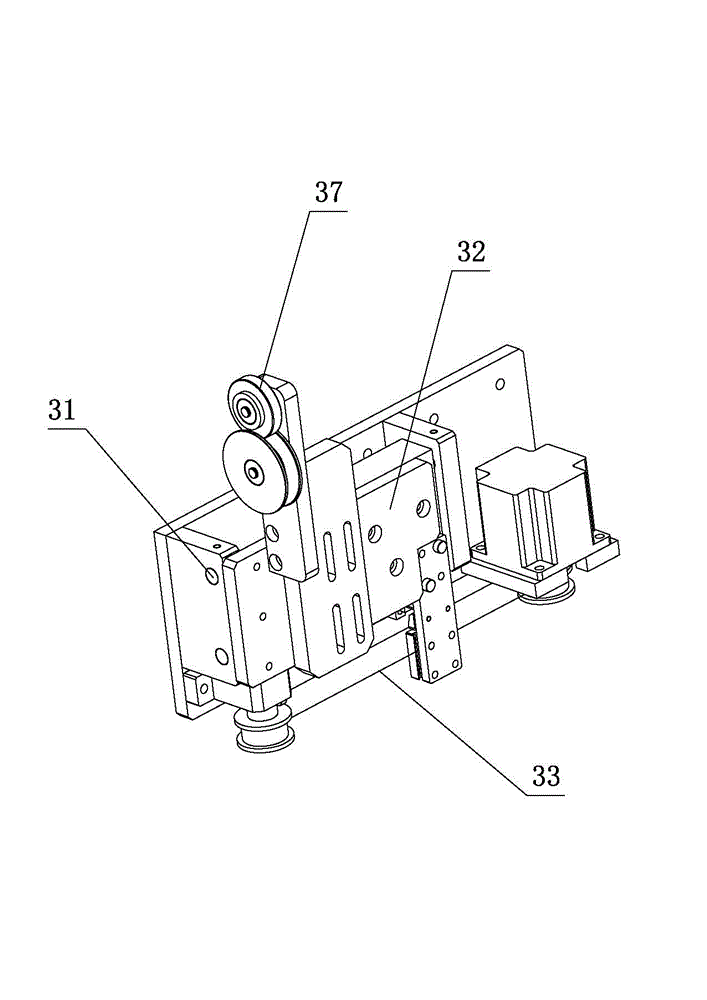

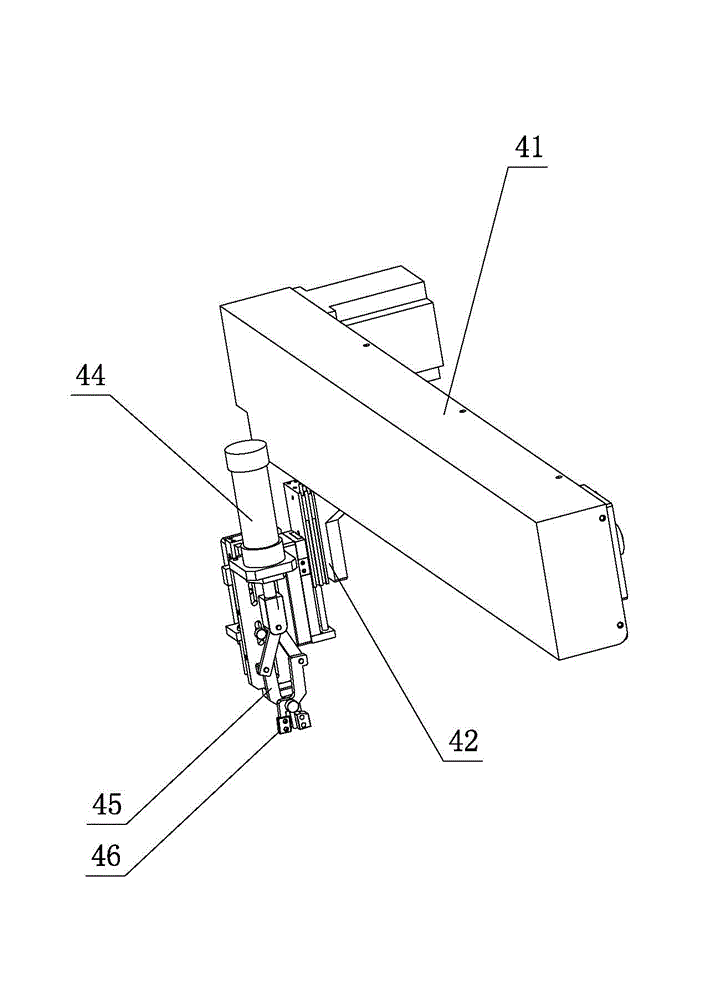

[0060] Such as Figure 1 to Figure 7 As shown, a wire automatic winding and cutting machine of the present invention includes a frame, the frame is provided with a winding device 2 for winding a wire coil 22, and the frame is also provided with a wire-drawing and cutting device. The upper line device 4, the cable tie cutting device 5 for cutting the cable tie 23, the cable tie wrapping device 6 for enclosing the cable tie 23 on the wire coil 22, the cable tie 23 for tightening the cable tie 23 on the wire coil 22 A belt tightening device 7 and an automatic clamping and unwinding device 8 for clamping and unloading the coil 22, the cable tie wrapping device 6 and the cable tie tightening device 7 are respectively arranged on both sides of the coil winding device 2; The cable tie winding device 6 is slidably connected to the frame and reciprocates between the winding device 2 and the cable tie cutting device 5, and the upper thread device 4 is slidably connected to the incoming ...

Embodiment 2

[0074] Such as Figure 8 to Figure 12 As shown, the difference between this embodiment and Embodiment 1 is: the all-in-one machine of this embodiment has a peeling function, and the method includes the following steps:

[0075] 1), the upper wire device 4 clamps and pulls the wire to the winding device 2, the upper wire device 4 hands the wire to the automatic clamping and unwinding device 8 of the winding device 2 to clamp, and the upper wire device 4 resets to the front end of the peeling device 10 ; 2), the wire arranging device 3 rises to position the wire, and the wire winding device 2 winds the wire. During the winding process of the wire, the wire arranging device 3 drives the wire to swing back and forth along the central axis of the coil 22 to make the wire evenly Winding in the winding device 2; 3), during the winding process of the wire rod, the cable tie wrapping device 6 moves to the cable tie cutting device 5, and the cable tie cutting device 5 inserts the cable ...

Embodiment 3

[0082] Such as Figure 13 As shown, the difference between this embodiment and Embodiment 1 is that: one side of the cable tie wrapping device 6 is provided with a winding stopper mechanism for assisting the winding device 2 in winding a large wire coil 22, the The winding retainer mechanism includes a support frame 111, a follower shaft 112 and a wire retainer 113, the support frame 111 is fixedly connected to the X-Y motion platform 67, the follower shaft 112 is connected to the upper end of the support frame 111, and the retainer The wire reel 113 is connected to the rotating shaft 112 . When the winding device 2 winds a larger wire reel 22, in order to prevent the wire reel 22 from sliding down, a winding stop mechanism is provided. The winding retainer mechanism and the cable tie wrapping device 6 move synchronously under the control of the X-Y motion platform 67. When the cable tie wrapping device 6 slides to the cable tie shearing device 5 to take the cable tie 23, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com