Full-automatic coiling machine

A fully automatic winding machine and winding mechanism technology, which is applied in coil manufacturing, circuit/collector parts, electrical components, etc., can solve the problems of increased processing cost, low processing efficiency, and low precision, so as to ensure precision Requirements, the number of coil turns is uniform, and the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

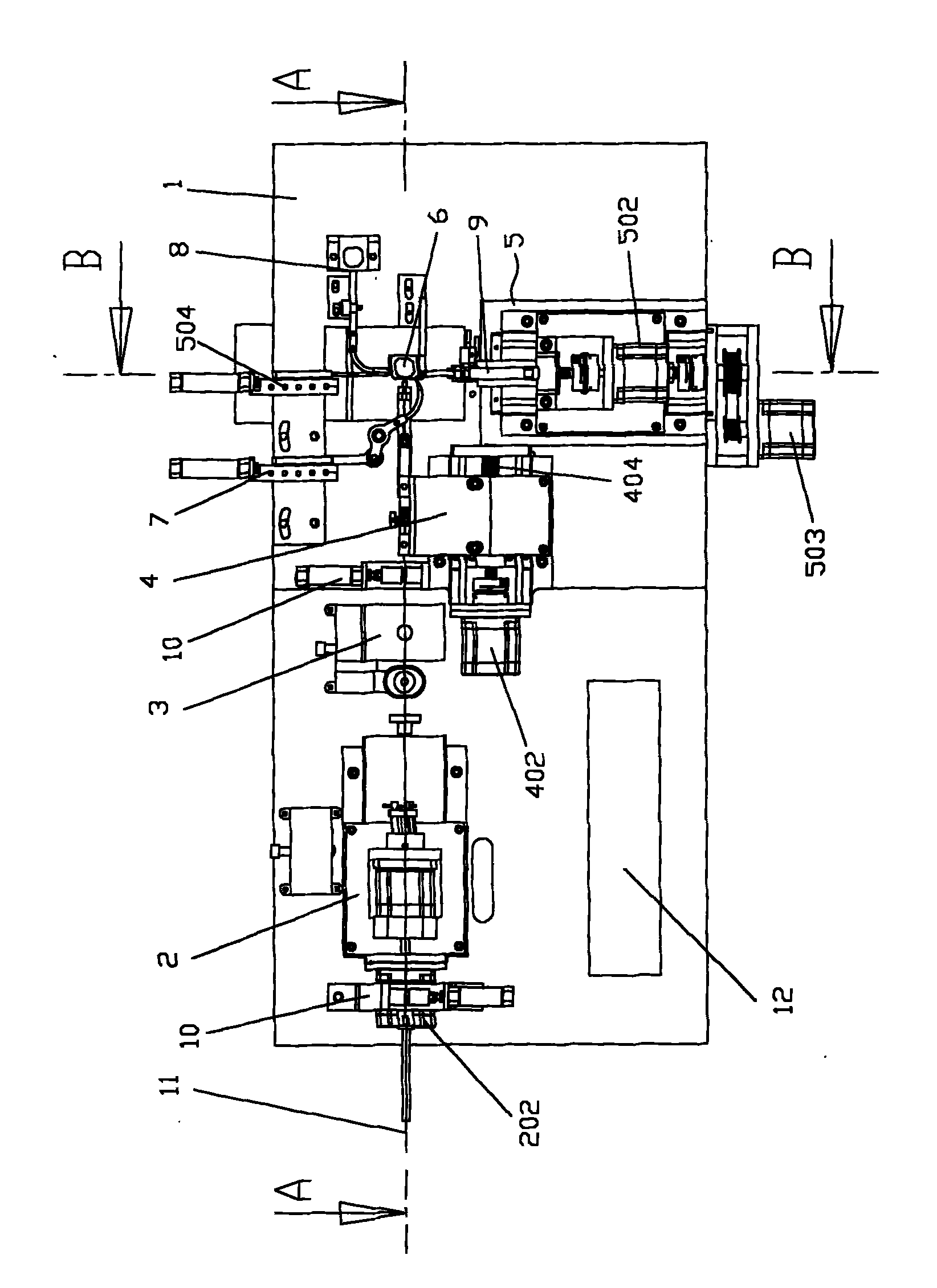

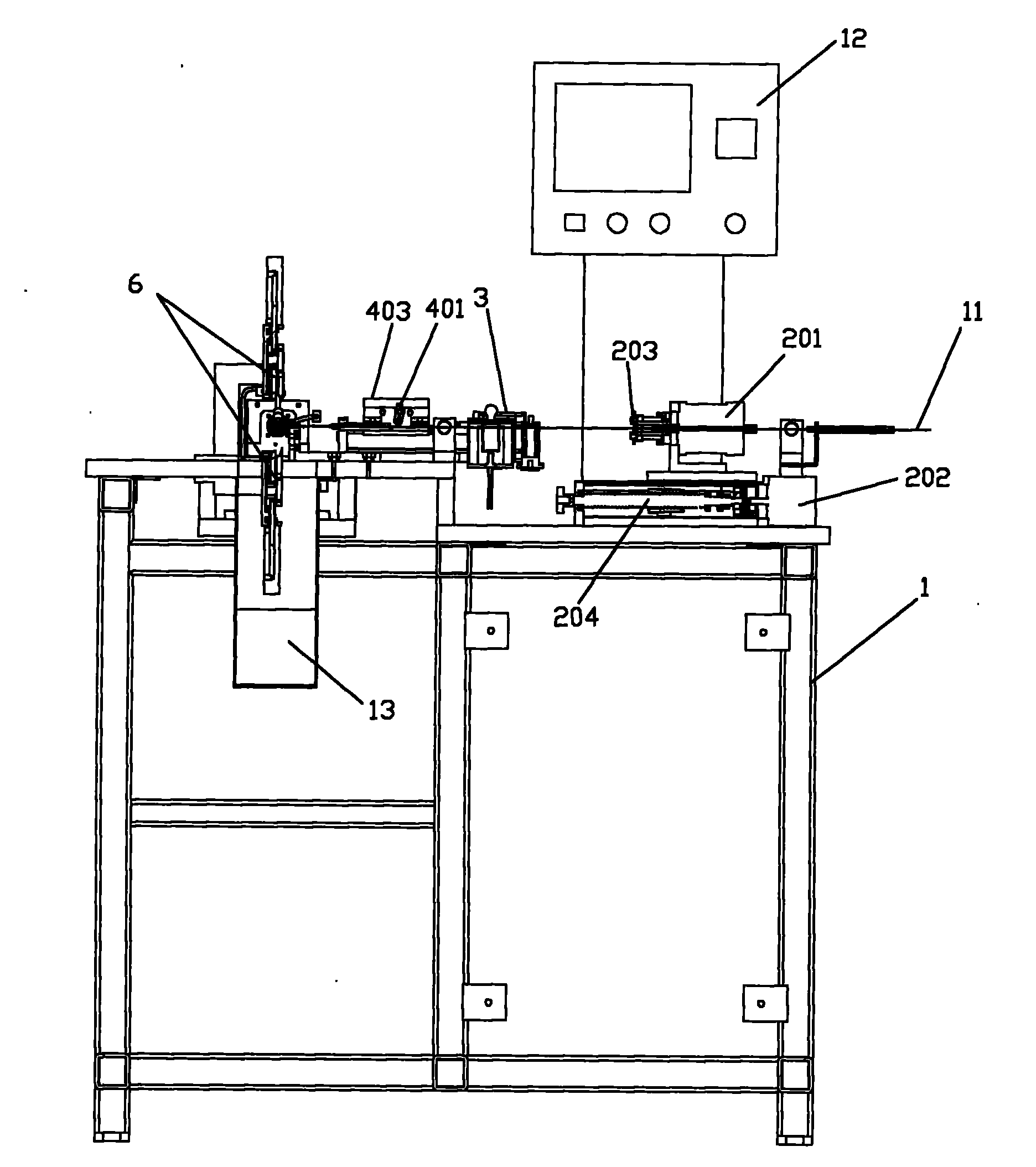

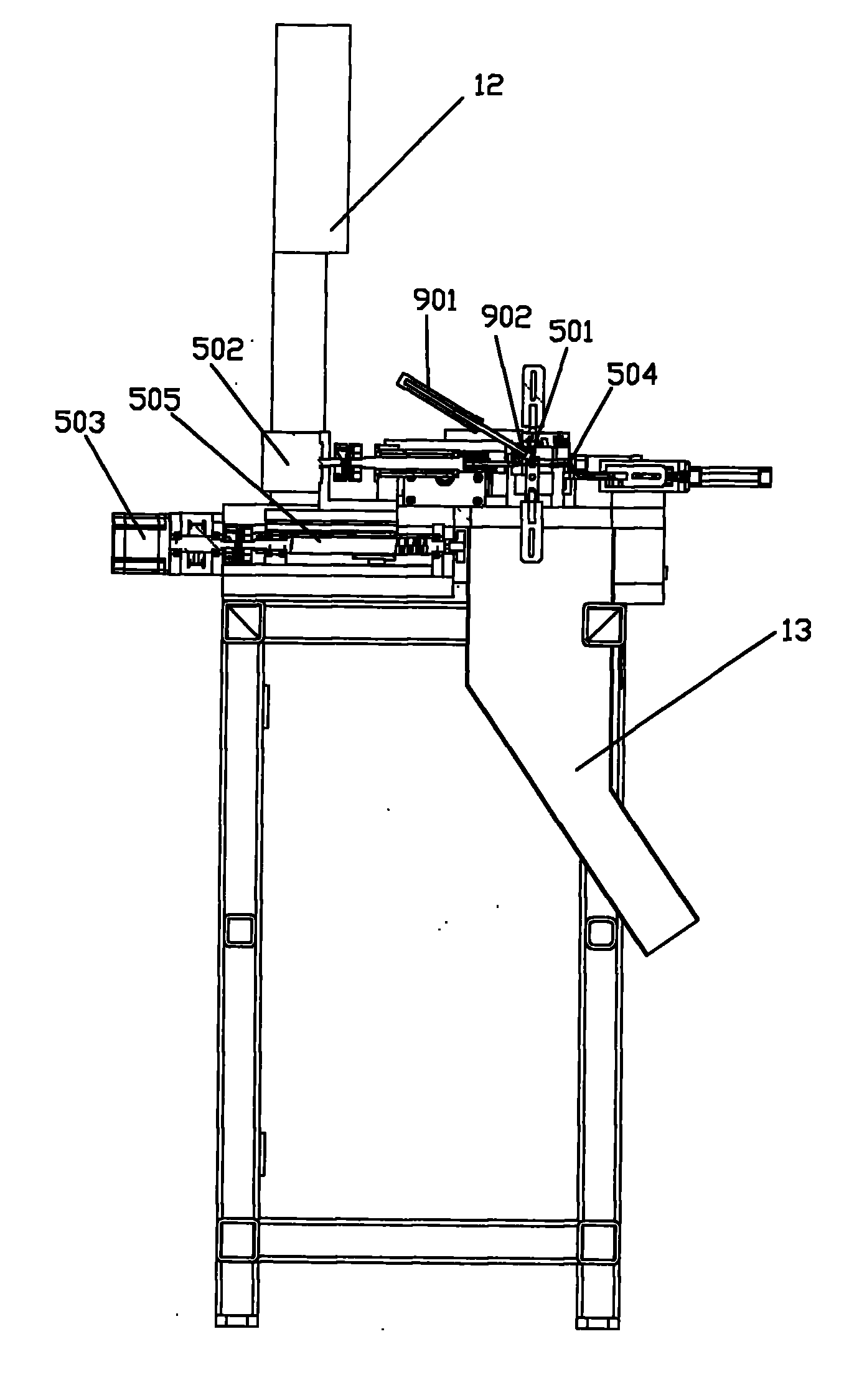

[0019] Such as figure 1 As shown, the winding machine of the present invention is used for winding air-core coils used in the electronic communication industry, especially micro-miniature inductance coils. It includes a workbench 1 and stripping coils arranged on the workbench 1 in sequence according to the input direction of copper wires. Mechanism 2, tin furnace 3, wire feeding mechanism 4, winding mechanism 5, cutting device 6, and the main controller that controls the actions of the above components, wherein the winding shaft 501 in the winding mechanism 5 realizes the winding and cutting of the copper wire 11 The device 6 drives two cutting knives simultaneously by the upper and lower cylinders to cut off the copper wire 11. The first forming assembly 7 and the second forming assembly 8 are arranged beside the winding shaft 501, both of which include a driving cylinder and are driven by the driving cylinder. After the winding and cutting processes are completed, the stitc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com