Tunnel drilling machine with drill rod automatic loading and unloading functions for remote control

An automatic loading and unloading and remote control technology, which is applied to drill pipes, drilling automatic control systems, drilling pipes, etc., can solve the problems of casualties, low drilling efficiency, and prone to errors, etc., and achieve high automation and high disassembly efficiency , to avoid the effect of slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

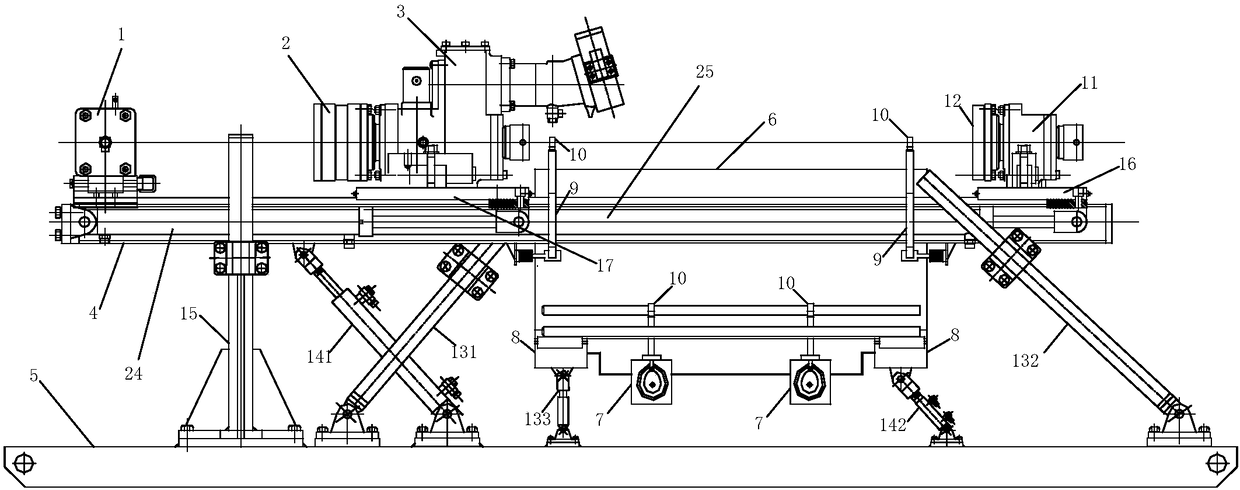

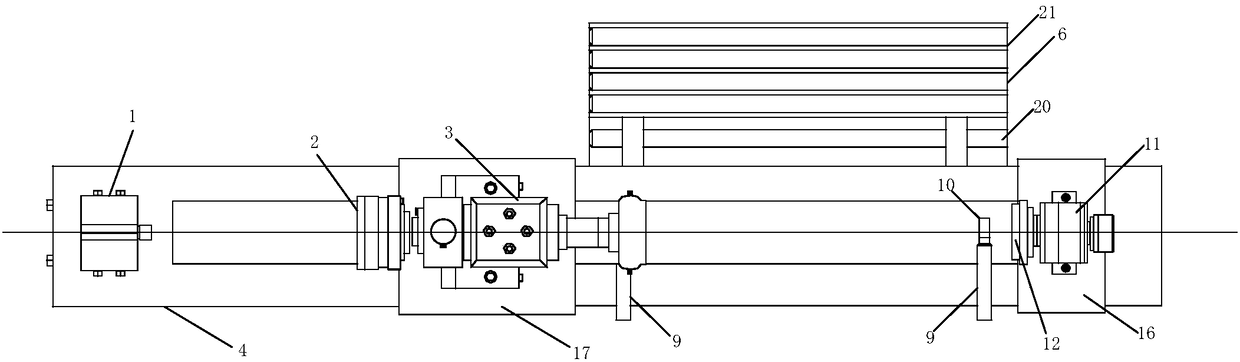

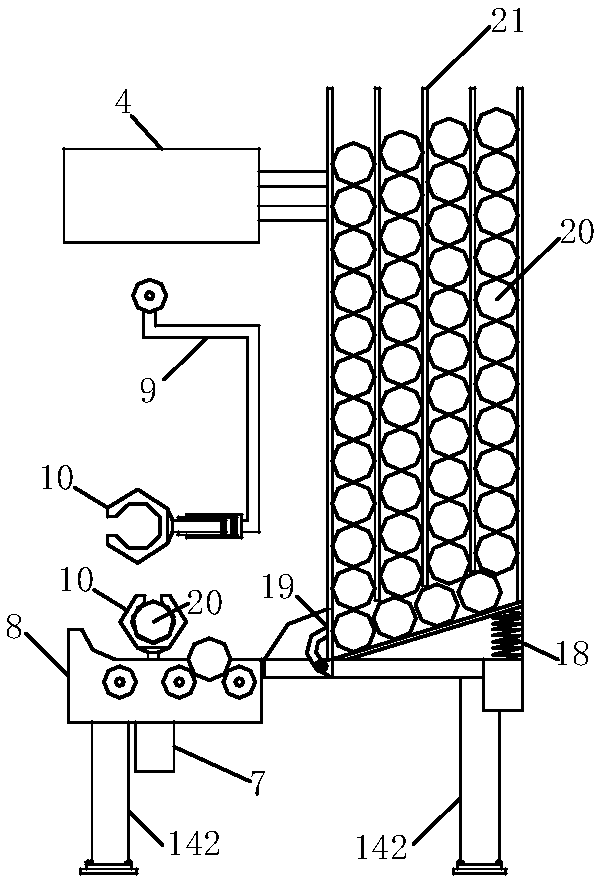

[0027] like Figure 1 to Figure 7 As shown, this embodiment provides a tunnel drilling machine for automatic loading and unloading of drill pipes for remote control, which includes a base 5, a support mechanism, a carriage 4, a drill pipe transmission unit and the like. The base 5 is connected to the carriage 4 through a support mechanism, wherein the support mechanism includes a column 15, a front support rod 131, a rear support rod 132 and a front support cylinder 141, the column 15 is arranged on the front end of the base 5, and the carriage 4 is slidably connected through a sliding sleeve Column 15, the front end of one end hinge base 5 of front support rod 131, the front end of the other end hinge carriage 4 of front support rod 131, the rear end of one end hinge base 5 of rear support rod 132, the other end hinge of rear support rod 132 The rear end of the carriage 4, the front end of one end of the front support cylinder 141 is hinged to the base 5, and the other end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com