High-torque drilling machine with power-shifting gearbox

A power shifting and gearbox technology, applied in the field of high-torque drilling rigs, can solve problems such as difficult meshing, damage, and safety accidents of shifting gears, and achieve the effects of reasonable and compact structure design, simple operation, and good disassembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

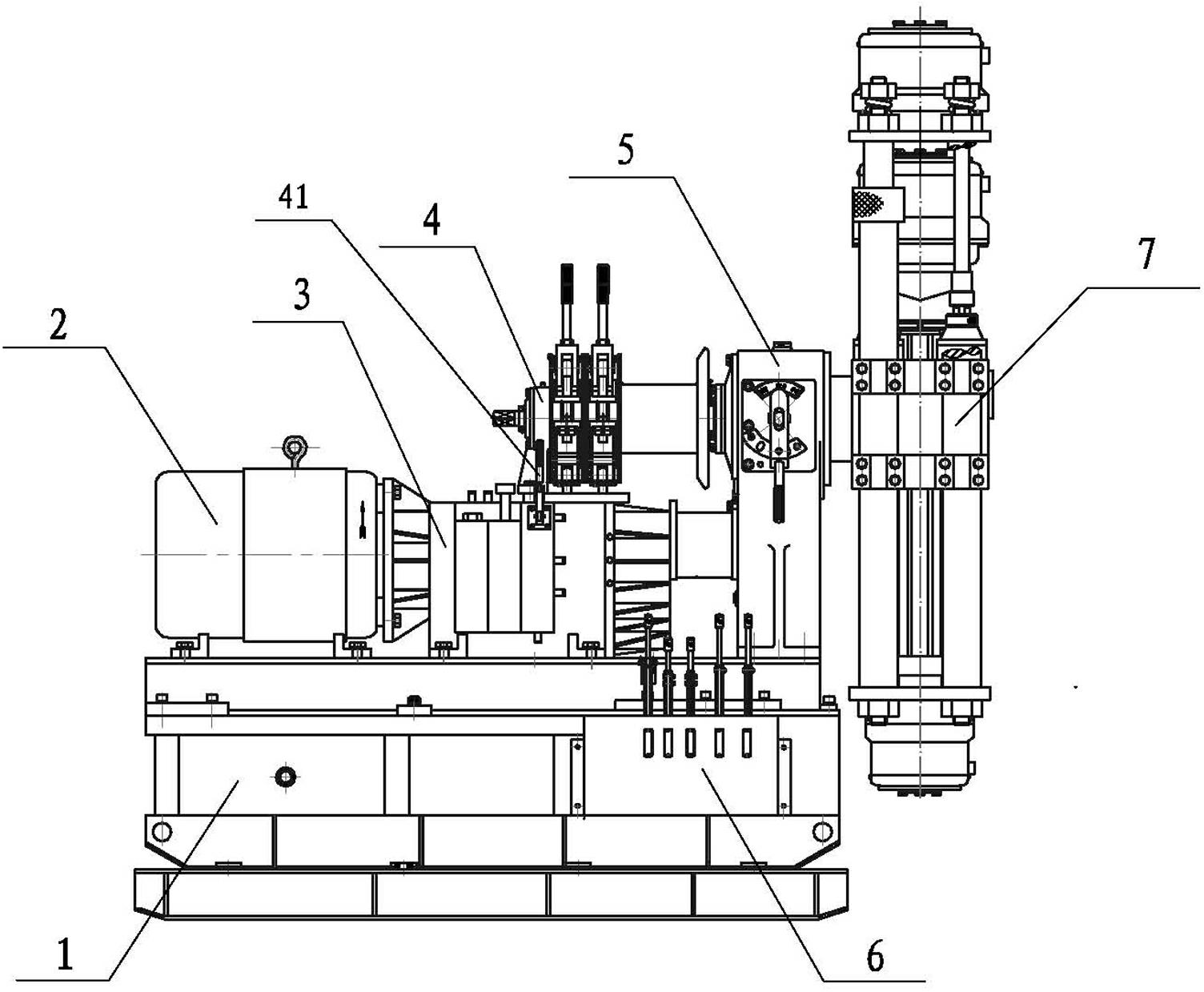

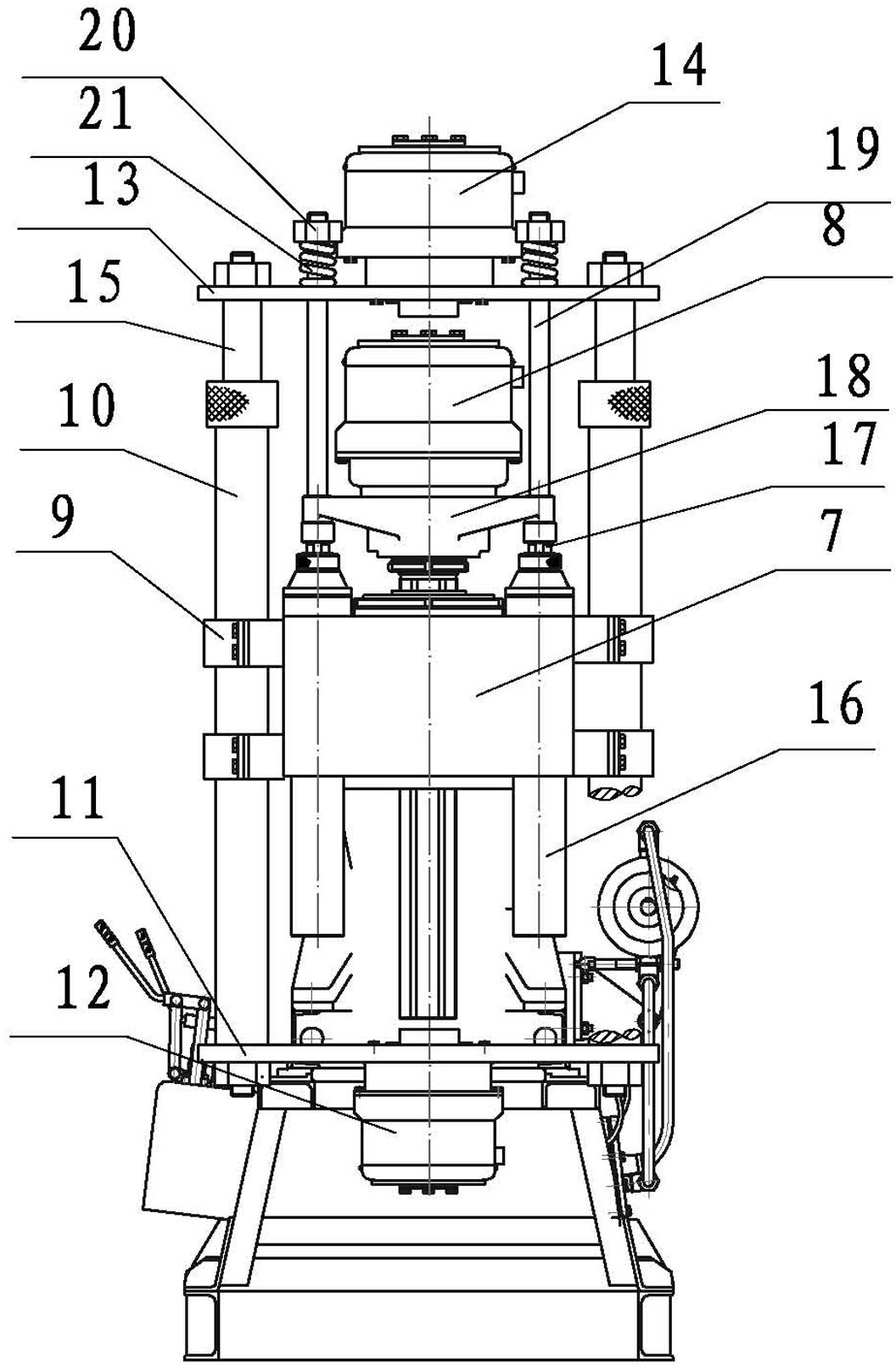

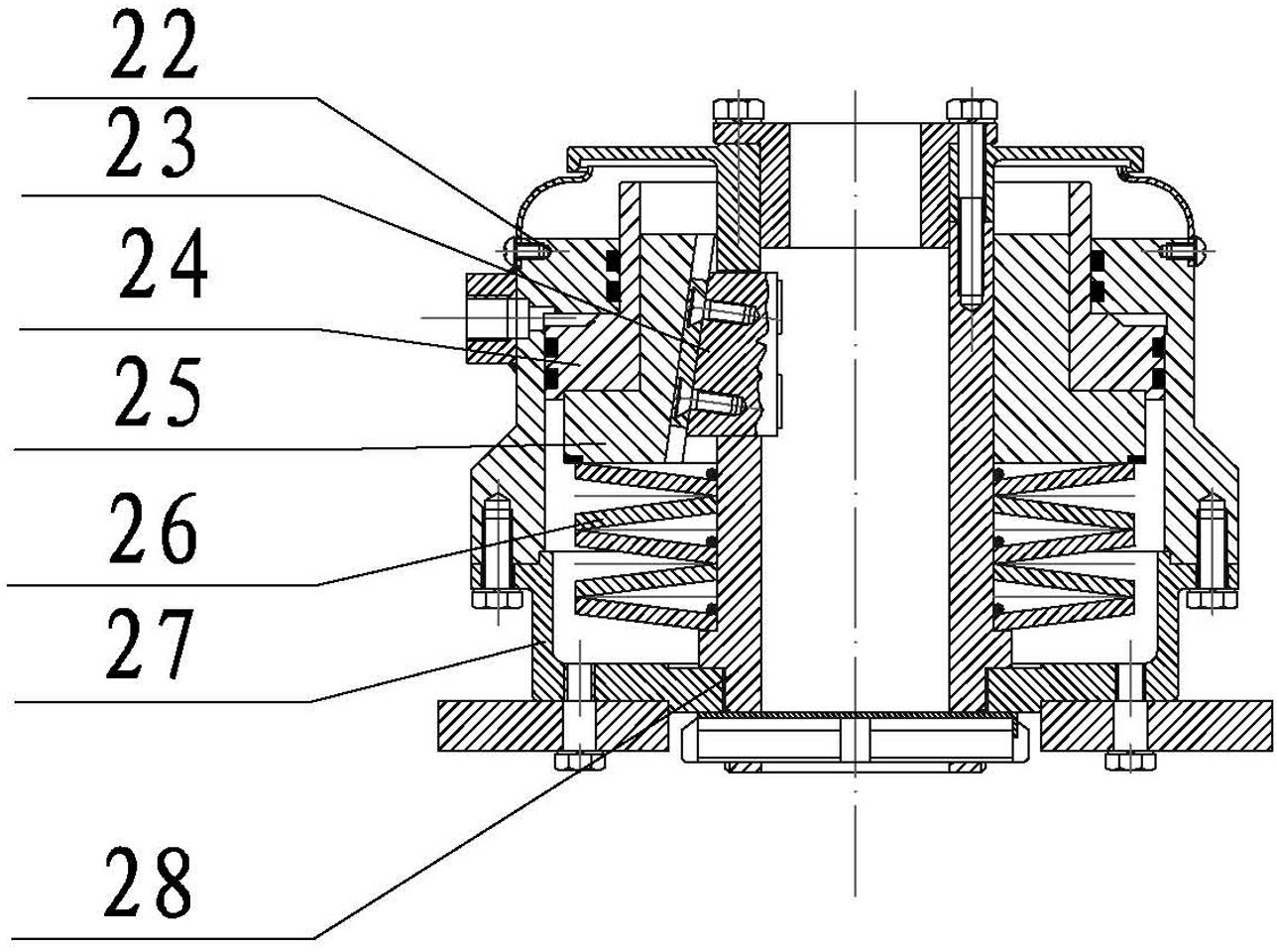

[0016] Example: such as figure 1 , a high-torque drilling rig with a power shift gearbox, including a frame 1, a motor 2, a gearbox 3, a transfer case 5, a winch 4, a gyrator 7 and a control part 6, wherein the gyrator 7 is provided with a piston Cylinder 16, the piston cylinder 16 is provided with a piston rod 17 matched with it, the piston rod 17 is fixed with a beam 18, the beam 18 is provided with a hydraulic chuck 8, and the two sides of the gyrator 7 are provided with four pairs of casing pressure plates 9, A sleeve 10 is fixed inside the sleeve pressure plate 9, a front clamper fixing plate 11 is fixed at the front end of the sleeve sleeve 10, a front clamper 12 is arranged on the front clamper fixing plate 11, and a front clamper 12 is arranged on the front end of the sleeve sleeve 10. Be provided with the slide bar 15 that can slide in sleeve pipe 10, be fixed with post clamper fixed plate 13 on the slide bar 15, be provided with post clamper 14 on the post clamper fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com