Electric motor stator scanning detection apparatus

A motor stator, scanning detection technology, applied in the direction of measuring device, electric device, motor generator test, etc., can solve the problem of inability to judge the quality of the motor stator and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

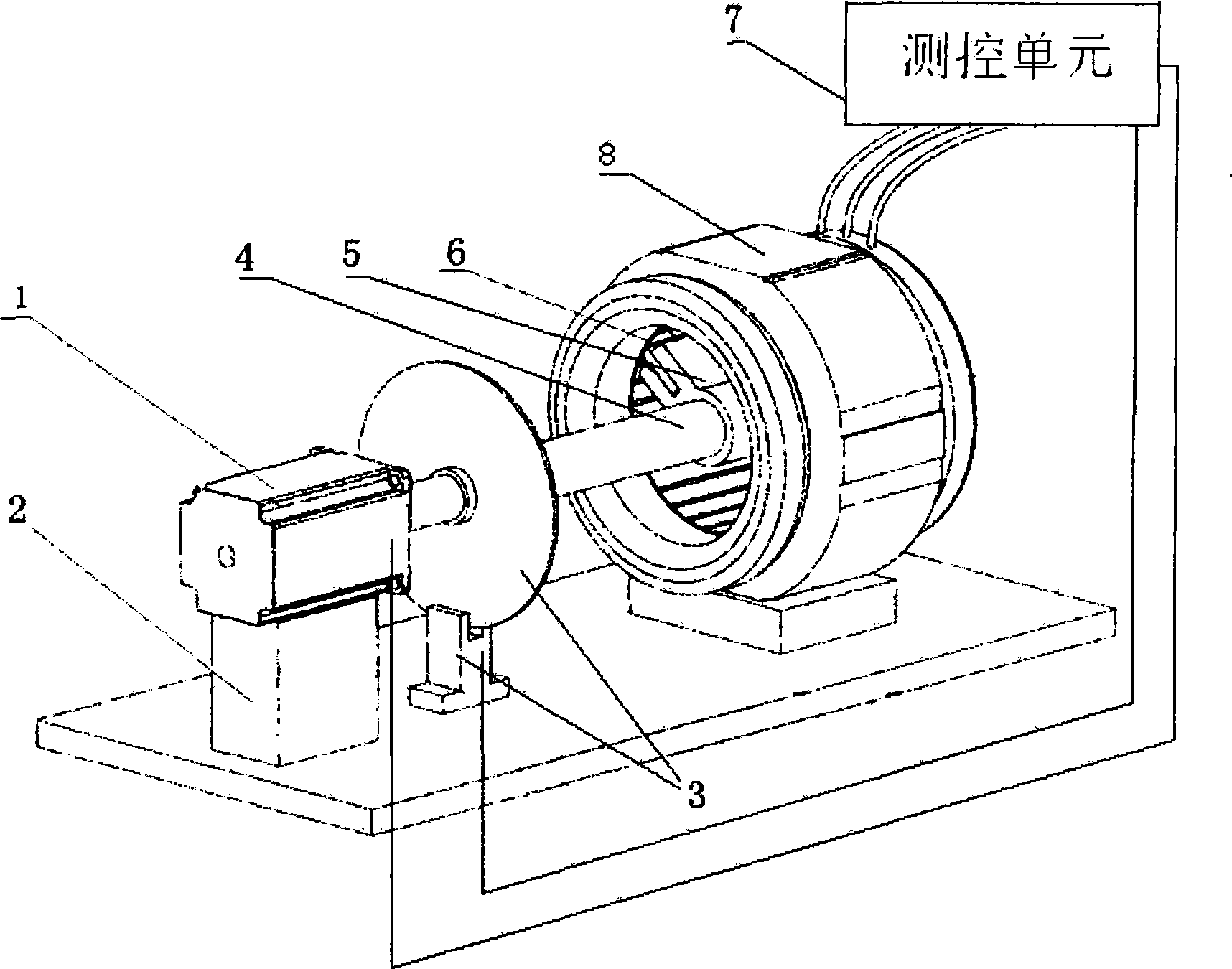

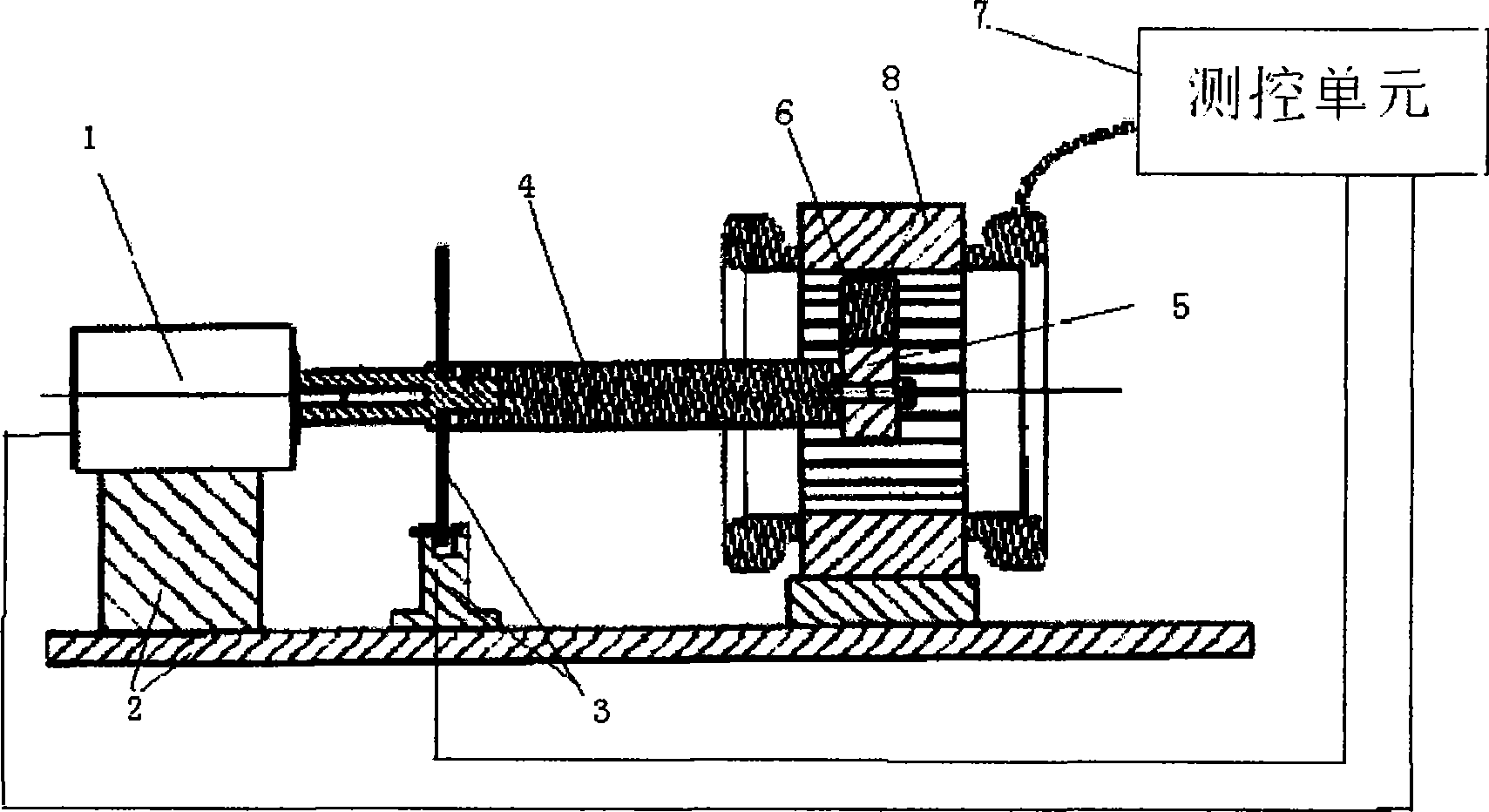

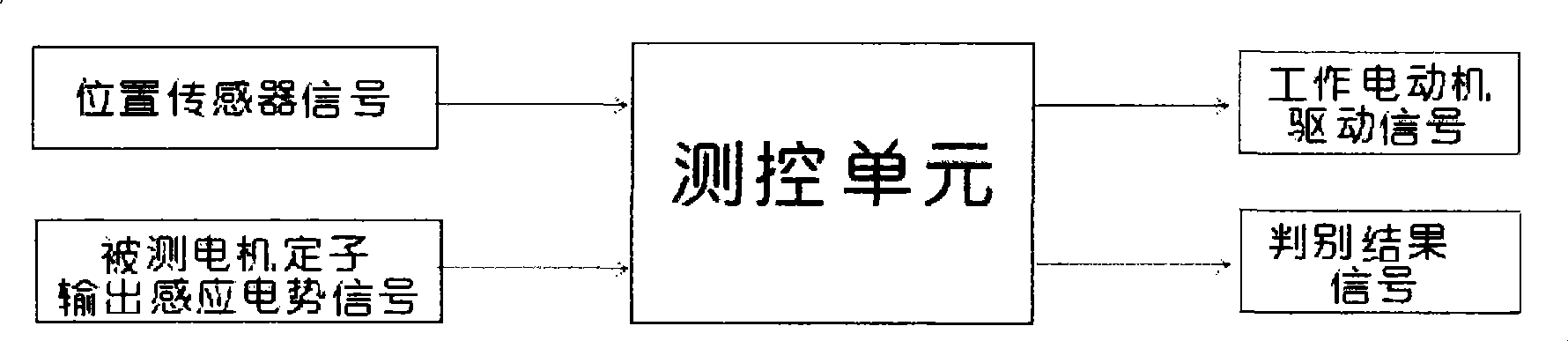

[0022] The motor stator scanning detection device of this embodiment consists of a working motor 1, a fixing frame 2, a position sensor 3 for detecting the azimuth angle, a coupling shaft 4 for connecting the rotating shaft of the working motor and the rotating body, and a fixing device for determining the detection position. The revolving body 5, a detecting magnet 6 for rotating and scanning around the stator axis of the motor under test, and a measurement and control unit 7 for detecting the induced electromotive force of the motor under test are formed. The working motor 1 is fixed on the fixed frame 2; the position sensor 3 is divided into two parts: a moving part and a position detecting part. Wherein, the moving part can be fixed on the rotating shaft or the coupling shaft 4 of the working motor 1, and the position detecting part is fixed on the fixing frame 2. The rotating body 5 is fixed on the rotating shaft or coupling shaft 4 of the working motor, and the detecting mag...

Embodiment 2

[0031] The basic structure of the motor stator scanning detection device of this embodiment is the same as that of the first embodiment. The only difference is that this embodiment uses the rotating shaft of the working motor 1, the coupling shaft 4 and the revolving body 5 to drive the detection magnet 6 along the stator of the motor under test. Rotate scanning of the outer wall surface, see Figure 5.

Embodiment 3

[0033] The motor stator scanning detection device of this embodiment is a device suitable for detecting the stator of a large motor. A motor stator scanning detection device, including a working motor 1, a movable positioning bracket 2'of the working motor, a position sensor 3 for detecting the azimuth angle, a coupling shaft 4 for connecting the rotating shaft of the working motor and a rotating body, and a fixed detecting magnet 6, the adjustable revolving body 5', the detecting magnet 6 for rotating and scanning around the stator of the motor under test, and the measurement and control unit 7 for testing the electromotive force of the stator 8 of the motor under test; characterized in that: the working motor 1 moves through the working motor The positioning bracket 2'is fixed inside the stator of the motor under test; the position sensor 3 is divided into two parts, a moving part and a position detection part, which are respectively fixed on the rotating shaft or coupling shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com