Concrete spray mechanical arm

A technology of concrete spraying and mechanical arm, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc. It can solve the problems of large working space requirements, large moving inertia of the mechanical arm, and large working range, and achieve high operating efficiency and flexible movement , the effect of a large working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

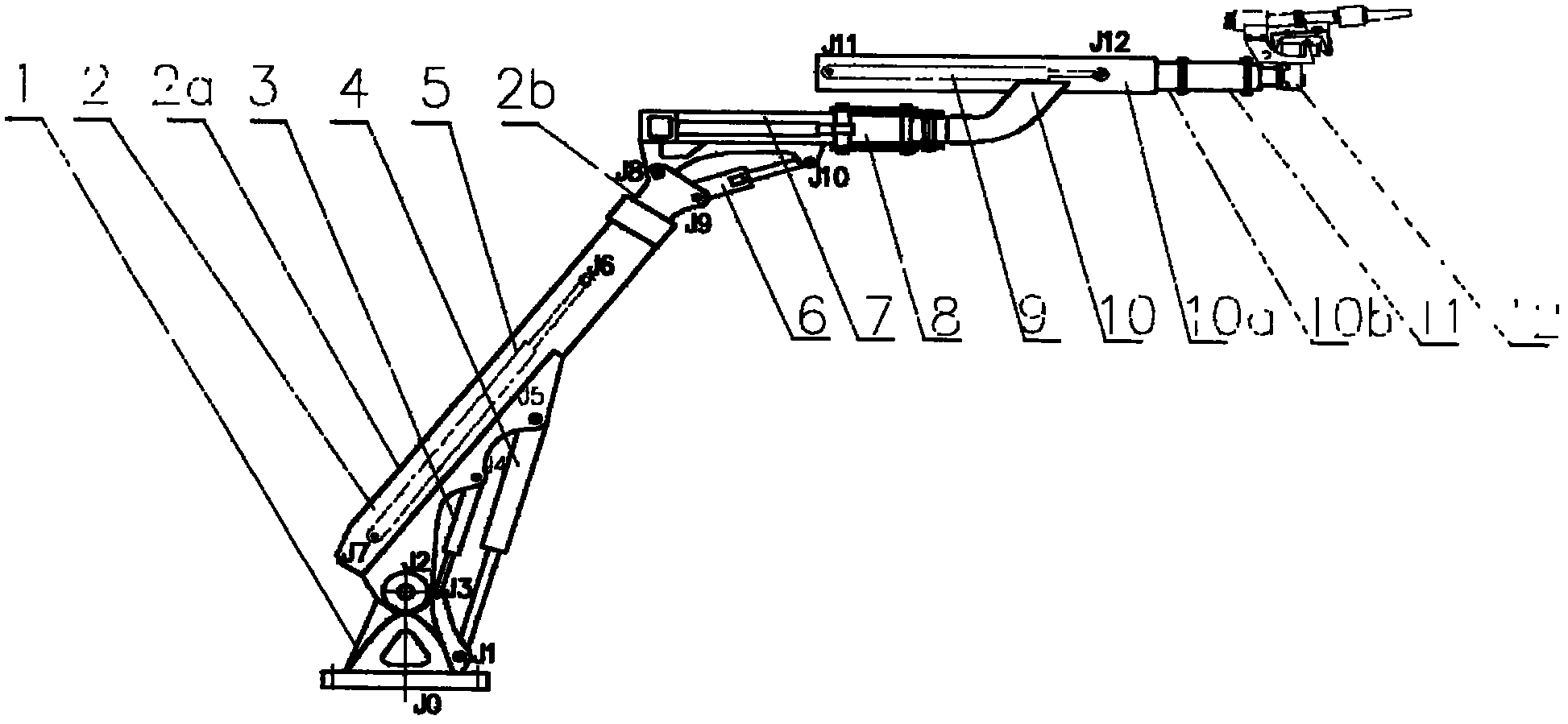

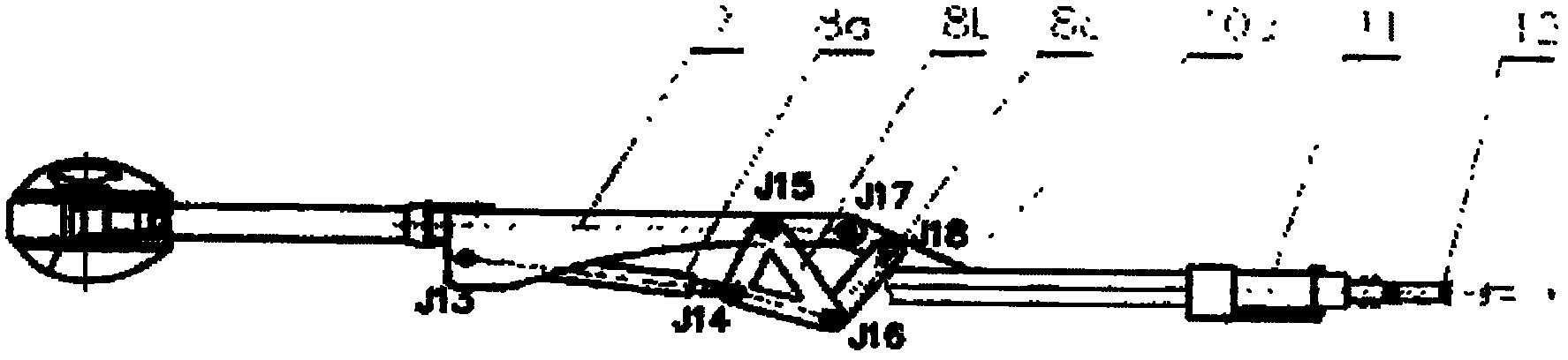

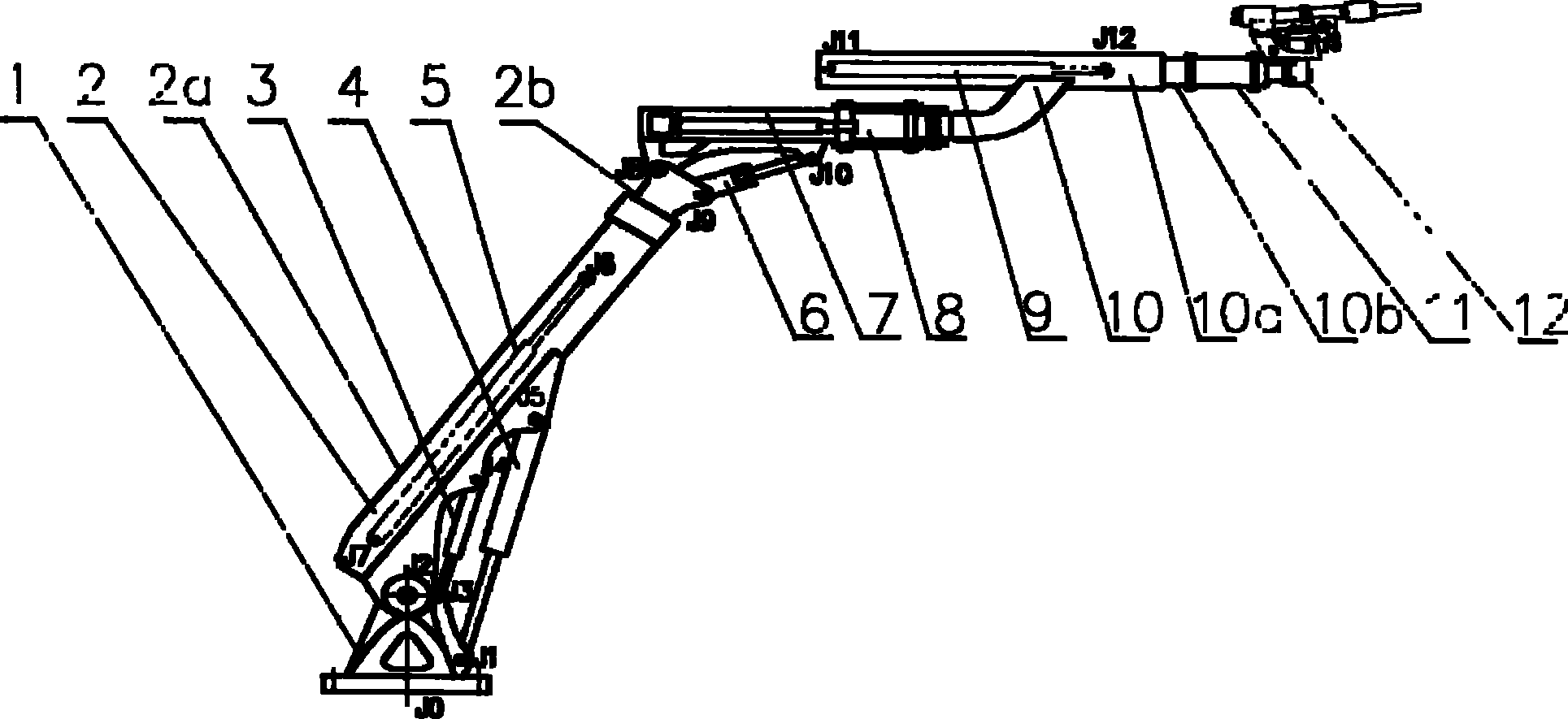

[0017] For implementation see figure 1 and figure 2 .

[0018] The mechanical arm is mainly composed of a rotary support 1, a large arm 2, a middle arm 8, a small arm 10, a small arm swing mechanism 8, a small arm parallel mechanism, and a nozzle wrist rotator 11. The rotary support 1 is installed on the frame of the shotcrete machine and can rotate around the axis J0.

[0019] The boom 2 is composed of the boom outer arm 2a, the boom inner arm 2b, the boom telescopic cylinder 5, the boom lifting main cylinder 4, and the boom lifting auxiliary cylinder 3; The support 1 is hinged, the two ends of the boom lifting main oil cylinder 4 are respectively hinged with the rotary support 1 and the boom outer arm 2a through the hinge shafts J1, J5, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com