Dual turbulent spiral forced heat exchanging and automatic descaling device

A technology of strengthening heat exchange and automatic descaling, which is applied in the direction of cleaning heat transfer devices, heat exchanger shells, heat exchange equipment, etc. Operation and other problems to achieve the effect of enhancing heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

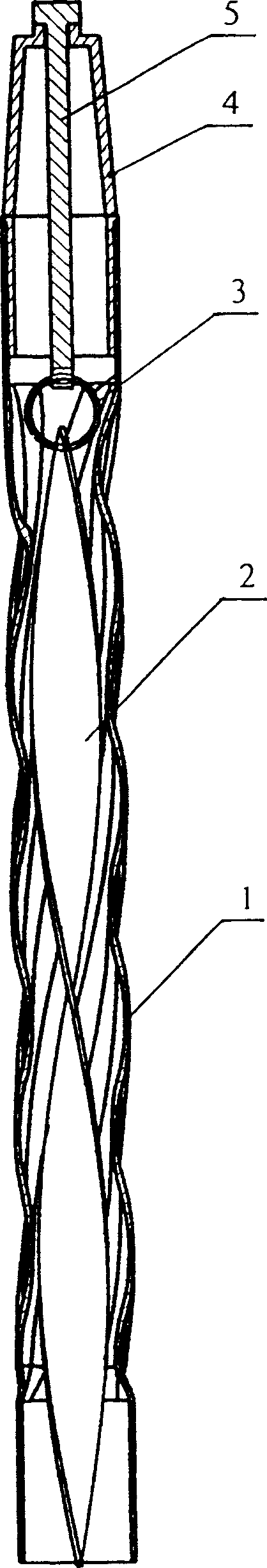

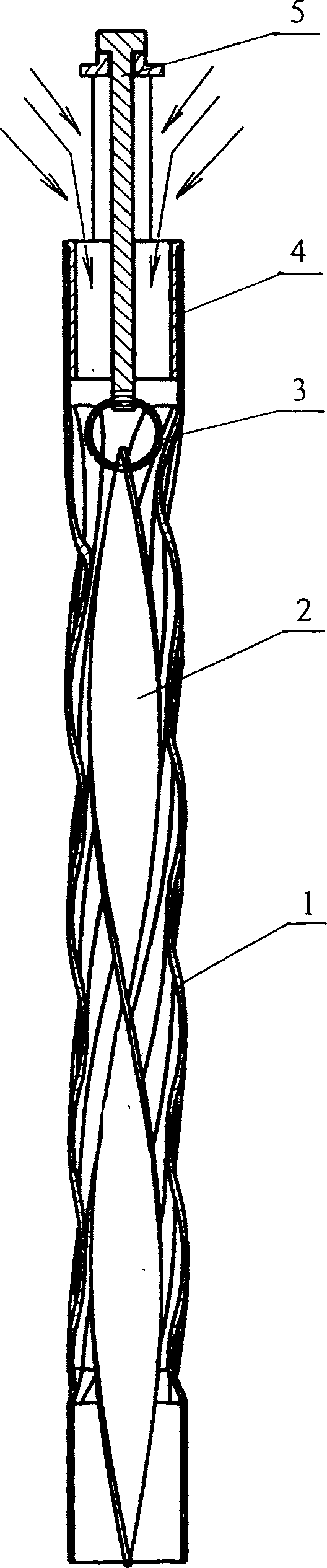

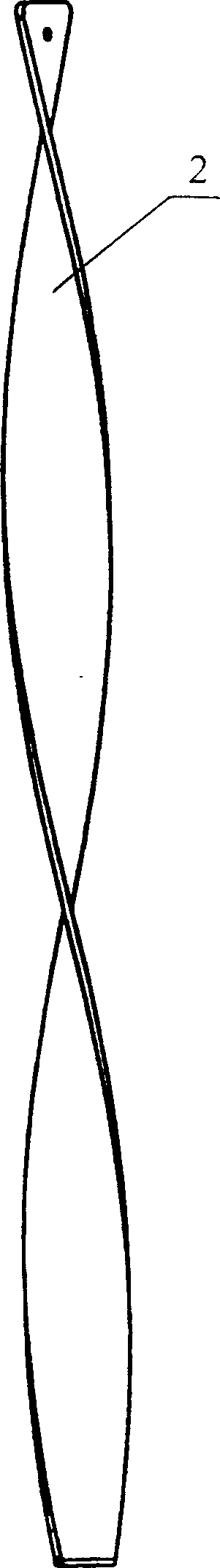

[0011] Such as figure 1 , figure 2 , image 3 As shown, it includes a helical tube 1, a spiral tie 2, a connecting rod 3, a fixed frame 4, and a rotating rod 5; The end point of the small end and one end point of the spiral bond 2 are hinged with a connector 3, and the outer cylindrical surface of the cylindrical end of the fixed frame 4 is equipped with a spiral tube with two ends in the shape of a circular tube, and the middle inner hole and outer circle are helical straight tubes 1.

[0012] The number of spiral heads in the middle spiral straight pipe is 3-5, the diameter of the spiral bond 2 is slightly smaller than the minimum inner diameter of the spiral pipe, and the length of the spiral bond 2 is equal to that of the spiral pipe 1. Connector 3 is a stainless steel wire. Rotating bar 5 and fixed frame 4 two parts are inlaid stainless steel respectively at the contact point, improve wear resistance, thereby prolong service life.

[0013] When working, the liquid w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com