Automatic cleaning system, air conditioner and control method

An automatic cleaning and air-conditioning technology, which is applied in space heating and ventilation control input, control input related to air characteristics, air-conditioning system, etc., can solve problems such as lack of cleaning, low efficiency, and high exhaust temperature, and achieve timely Efficient cleaning, cost reduction, and water saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

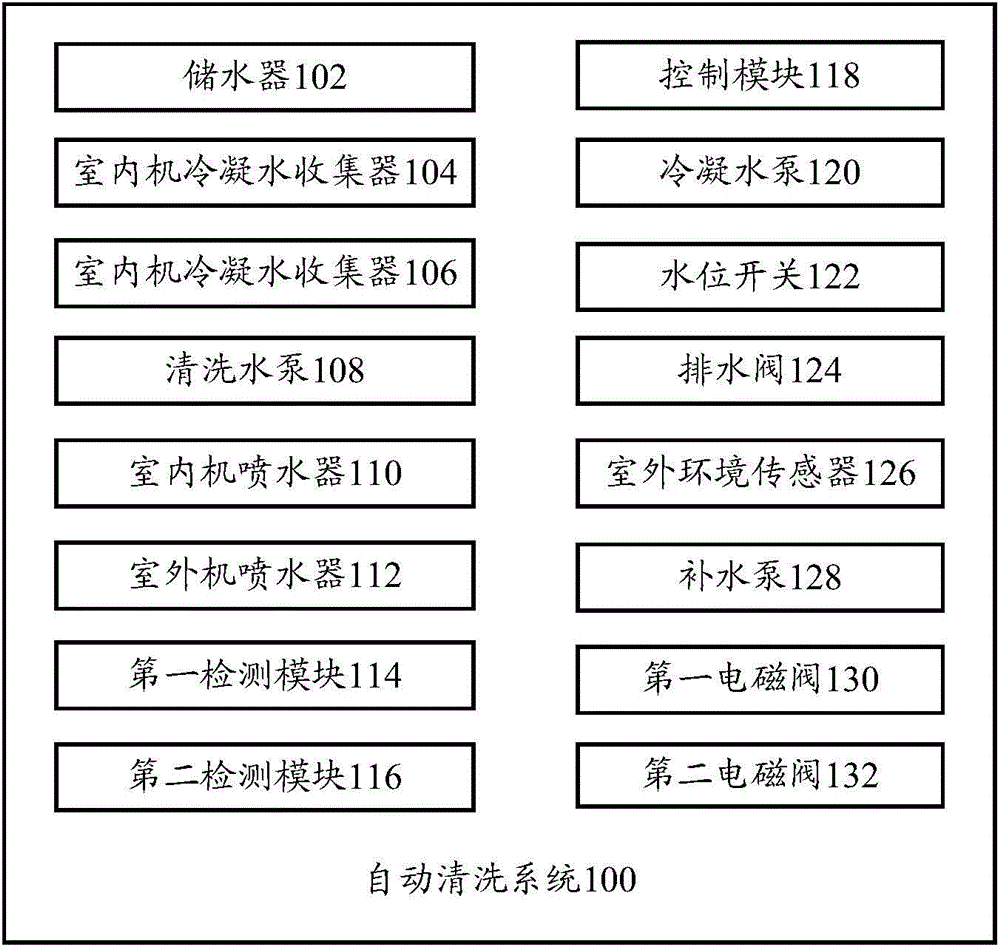

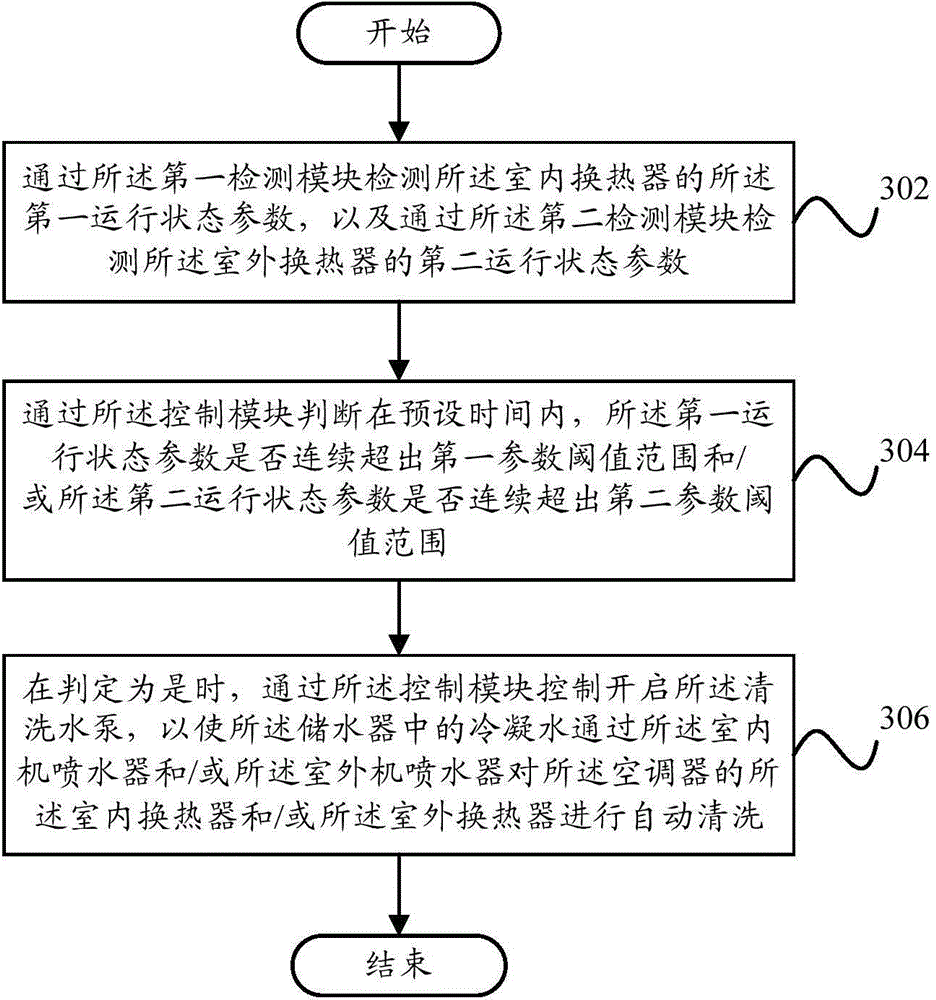

[0067] The first detection module 114 and the second detection module 116 are differential pressure sensors respectively, that is, by arranging differential pressure sensors at the heat exchanger of the indoor unit and the heat exchanger of the outdoor unit, the pressure difference on both sides of the heat exchanger is measured. The more serious the dust accumulation on the heat exchanger, the greater the pressure difference, so you can set the upper limit value of the pressure difference of the heat exchanger at each wind speed, for example, set the upper limit value: set the heat exchanger under the condition of moderate dust accumulation The pressure difference measured below is set as the upper limit value y of the pressure difference of the current wind gear; then, when the outdoor unit fan or the indoor unit fan is running at x gear, the pressure difference p (operating state parameter) is detected in real time, and Compared with the upper limit value of the pressure dif...

Embodiment ( 2

[0069] The first detection module 114 and the second detection module 116 are wind speed sensors respectively, that is, by arranging wind speed sensors at places where the wind speed of the indoor heat exchanger and outdoor heat exchanger is relatively stable, the wind speed on the inner and outer surfaces of the heat exchanger is measured. , to collect fan wind speed in real time; the air conditioner sets the reasonable range of wind speed for each wind gear in advance, for example, set the lower limit value: the lower limit voltage in the power supply fluctuation range of the air conditioner sales area, and the heat exchanger is in the case of moderate dust accumulation , the measured wind speed can be set as the lower limit value of the wind speed V1m / s of the current wind gear, and the set upper limit value is: the upper limit voltage in the power supply fluctuation range of the air conditioner sales area, and the heat exchanger has no dust accumulation, the measured The ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com