Closed circulating rotifer continuous culturing system

A culture system and closed-cycle technology, applied in the field of culture systems, can solve the problems of manpower, material resources and space occupation, environmental pollution, large demand, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

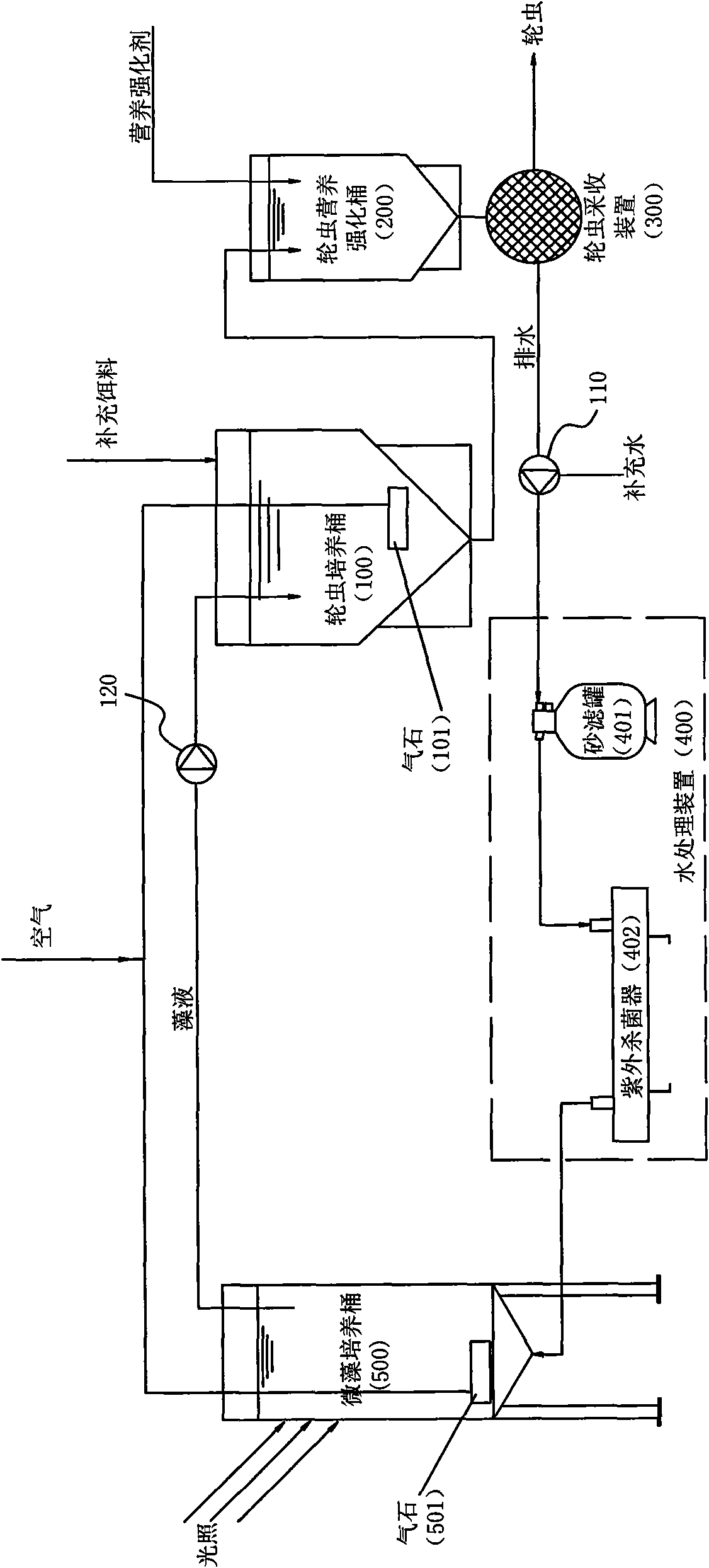

[0019] Such as figure 1 Shown, the closed cycle rotifer continuous culture system of the present invention, it is used for the rotifer culture barrel 100 that rotifer is cultivated, is used for the rotifer nutrition strengthening barrel 200 that rotifer carries out nutritional fortification, is used for harvesting after cultivating A rotifer harvesting device 300 for rotifers, a water treatment device 400 including physical filtration, biological filtration or disinfection, etc., and a microalgae cultivation tank 500 for specific microalgae cultivation and supply to the rotifer cultivation tank 100 are composed; the water treatment device 400 is composed of sand filter tank 401 and ultraviolet sterilizer 402.

[0020] The output end of the roti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com