Preparation method of high-rate polylactic acid foaming sheet

A polylactic acid foaming and high-magnification technology, which is applied to flat products, other household appliances, household appliances, etc., can solve the problems of low apparent density, easy perforation of materials, difficulty in controlling foam size and foaming ratio, and achieve Uniform cell diameter, uniform sheet thickness, easy control of foam size and expansion ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

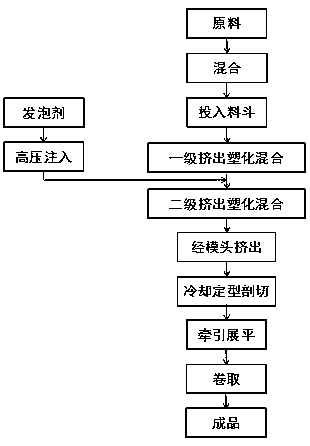

Image

Examples

Embodiment 1

[0049] (1) Primary extrusion

[0050] Measure 88 parts of polylactic acid and 2 parts of nucleating agent talcum powder in parts by mass, and inject them into the first-stage screw extruder. After the melt is plasticized and mixed in the first-stage extrusion, 5 Parts, 5 parts of auxiliary nitrogen are injected into the first-stage extruder, the injection pressure of foaming agent is at 18Mpa, and the injection pressure of nitrogen is at 11Mpa. Set the temperature of each section of the first-stage screw extruder, from the feeding to the machine neck, the temperature of the first zone is 180°C, the temperature of the second zone is 182°C, the temperature of the third zone is 190°C, the temperature of the fourth zone is 195°C, and the temperature of the fifth zone is 200°C, the temperature in the sixth zone is 200°C, the temperature in the seventh zone is 200°C, the temperature in the eighth zone is 200°C, the temperature in the ninth zone is 200°C, the temperature in the tenth...

Embodiment 2

[0062] (1) Primary extrusion

[0063] Measure 90 parts of polylactic acid and 2 parts of nucleating agent talcum powder in parts by mass, and inject them into the primary screw extruder. After the melt is plasticized and mixed in the primary extrusion, the blowing agent trifluorotrichloroethane 4 parts and 4 parts of auxiliary nitrogen are injected into the first-stage screw extruder, the injection pressure of foaming agent is 18Mpa, and the injection pressure of nitrogen is 12Mpa. Set the temperature of each section of the first-stage screw extruder, from the feeding to the machine neck, the temperature of the first zone is 182°C, the temperature of the second zone is 182°C, the temperature of the third zone is 190°C, the temperature of the fourth zone is 195°C, and the temperature of the fifth zone is 200°C, the temperature in the sixth zone is 200°C, the temperature in the seventh zone is 200°C, the temperature in the eighth zone is 200°C, the temperature in the ninth zone ...

Embodiment 3

[0072] (1) Primary extrusion

[0073] Measure 91 parts of polylactic acid and 2 parts of nucleating agent talcum powder into the first-stage screw extruder according to the number of parts by mass. After the melt is plasticized and mixed in the first-stage extrusion, 3.5 Parts, 3.5 parts of auxiliary nitrogen are injected into the first-stage screw extruder, the injection pressure of foaming agent is at 18Mpa, and the injection pressure of nitrogen is at 14Mpa. Set the temperature of each section of the first-stage screw extruder, from the feeding to the machine neck, the temperature of the first zone is 185°C, the temperature of the second zone is 188°C, the temperature of the third zone is 190°C, the temperature of the fourth zone is 195°C, and the temperature of the fifth zone is 200°C, the temperature in the sixth zone is 200°C, the temperature in the seventh zone is 200°C, the temperature in the eighth zone is 200°C, the temperature in the ninth zone is 200°C, the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com