Multifunctional model test system for tunnel and underground engineering

A technology for model testing and underground engineering, which is used in the testing of machine/structural components, measuring devices, instruments, etc., and can solve complex engineering problems and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

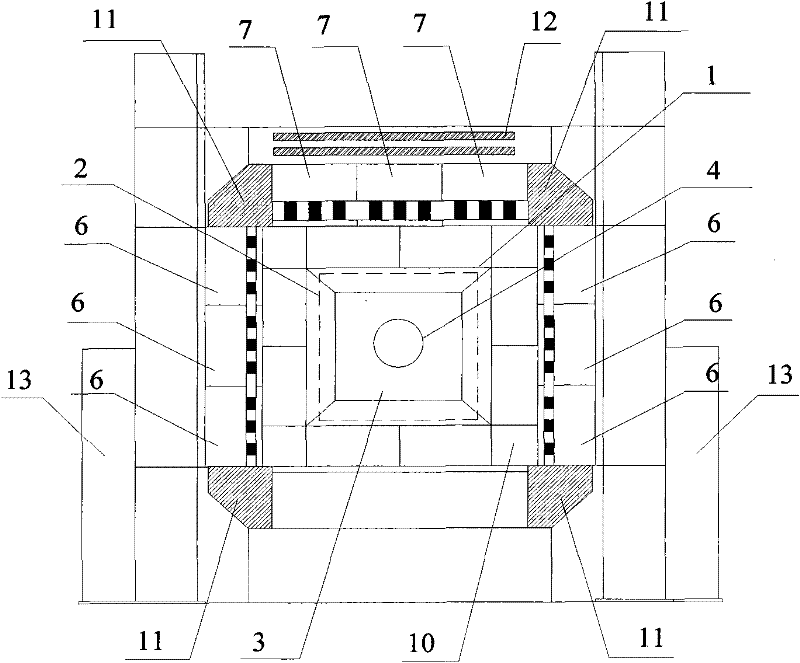

[0023] A multifunctional model test system for tunnels and underground engineering, the test system includes a track 12, a model box 10, a servo-controlled test loading device, a rotating seat, a rotating shaft, a rotating loading cylinder and a support, and there are two track 12, located in The top of the test system, the model box 10 is located in the middle of the test system, including the outer frame 1, the inner frame 2 and the plexiglass plate 3, the outer frame 1 and the inner frame 2 can be disassembled, and the plexiglass panel 3 is located in the model box 10, the plexiglass panel 3 is provided with a reserved hole 4, and the light transmittance of the plexiglass plate 3 is >95%. The servo-controlled test loading device includes a horizontal loading jack 6 and a vertical loading jack 7. There are six jacks 6, respectively located on both sides of the test system, three vertical loading jacks 7, located on the top of the test system, supporting piers 11 are also prov...

Embodiment 2

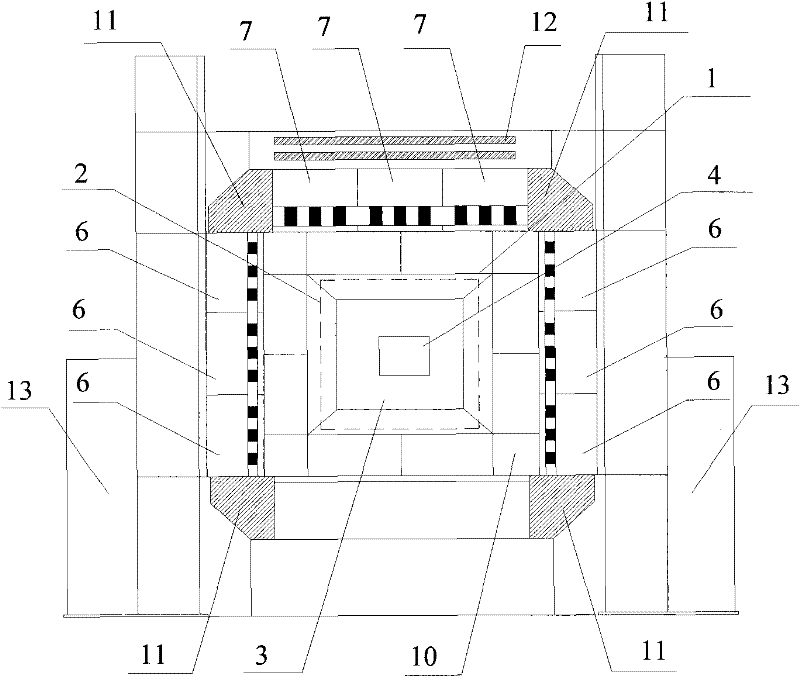

[0028] A multifunctional model test system for tunnels and underground engineering, the test system includes a track 12, a model box 10, a servo-controlled test loading device, a rotating seat, a rotating shaft, a rotating loading cylinder and a support, and there are two track 12, located in The top of the test system, the model box 10 is located in the middle of the test system, including the outer frame 1, the inner frame 2 and the plexiglass plate 3, the outer frame 1 and the inner frame 2 can be disassembled, and the plexiglass panel 3 is located in the model box 10, the plexiglass panel 3 is provided with a reserved hole 4, and the light transmittance of the plexiglass plate 3 is >95%. The servo-controlled test loading device includes a horizontal loading jack 6 and a vertical loading jack 7. There are six jacks 6, which are respectively arranged on both sides of the test system, three vertical loading jacks 7, which are arranged on the upper part of the test system, the ...

Embodiment 3

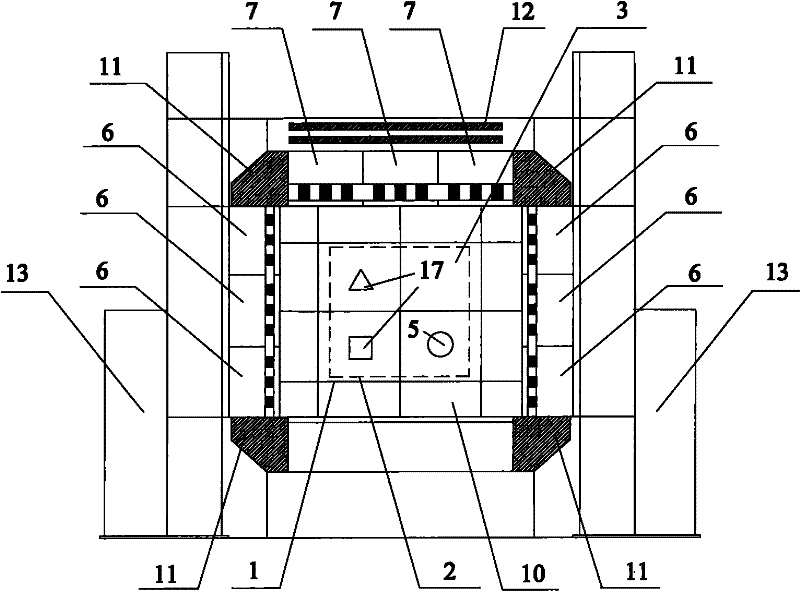

[0033]A multifunctional model test system for tunnels and underground engineering, the test system includes a track 12, a model box 10, a servo-controlled test loading device, a rotating seat, a rotating shaft, a rotating loading cylinder and a support, and there are two track 12, located in The top of the test system, the model box 10 is located in the middle of the test system, including the outer frame 1, the inner frame 2 and the plexiglass plate 3, the outer frame 1 and the inner frame 2 can be disassembled, and the plexiglass panel 3 is located in the model box 10, the plexiglass panel 3 is provided with an excavation hole 5, the light transmittance of the plexiglass plate 3 is >95%, the servo-controlled test loading device includes a horizontal loading jack 6 and a vertical loading jack 7, and the horizontal loading There are six jacks 6, which are respectively arranged on both sides of the test system, three vertical loading jacks 7, which are arranged on the upper part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com