A wire length measuring device

A technology of length measurement and equipment, applied in the field of wire harness inspection, can solve the problems of long time, large tensile force of tape, easy occurrence of blind spots, etc., and achieve the effects of convenient operation, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

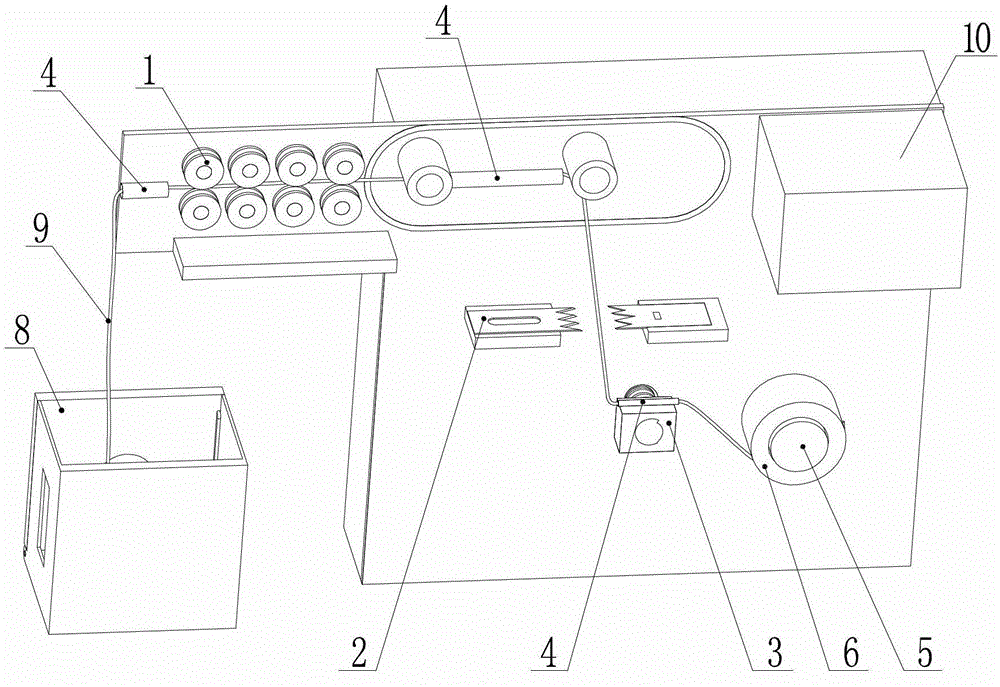

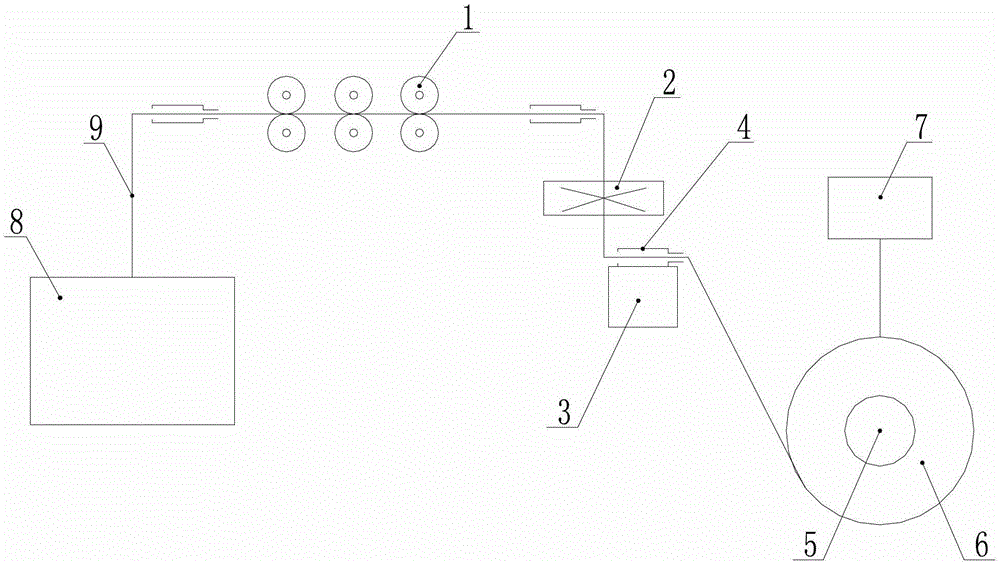

[0024] The following specific embodiments are listed below in conjunction with the accompanying drawings to further illustrate the present invention.

[0025] This embodiment is a kind of wire body length measuring equipment, such as figure 1 As shown, it includes a pressing wheel 1, a lateral adjustment block 3, a shearing device and a material receiving device; there are at least two pressing wheels 1, and the outer circumference of the pressing wheel 1 is provided with guide grooves, and the central axes of the pressing wheels are parallel; A guide wheel 4 is affixed on the lateral adjustment block 3, and the central axis of the guide wheel 4 is a through hole; the lateral adjustment block 3 is affixed to a worm, and the outer circumference of the worm is provided with a pin hole perpendicular to its central axis, and the pin The hole is matched with a pin shaft or a cylindrical pin; the worm and the worm gear are engaged and driven by a motor; the shearing device includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com