Large area VHF-PECVD reaction chamber back feed-in type parallel plate electrode capable of obtaining even electric field

A uniform electric field and parallel plate technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve problems such as plasma inhomogeneity, improve the uniformity of electric field distribution, and solve the uniformity of potential distribution Sexual problems, the effect of suppressing the potential standing wave effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

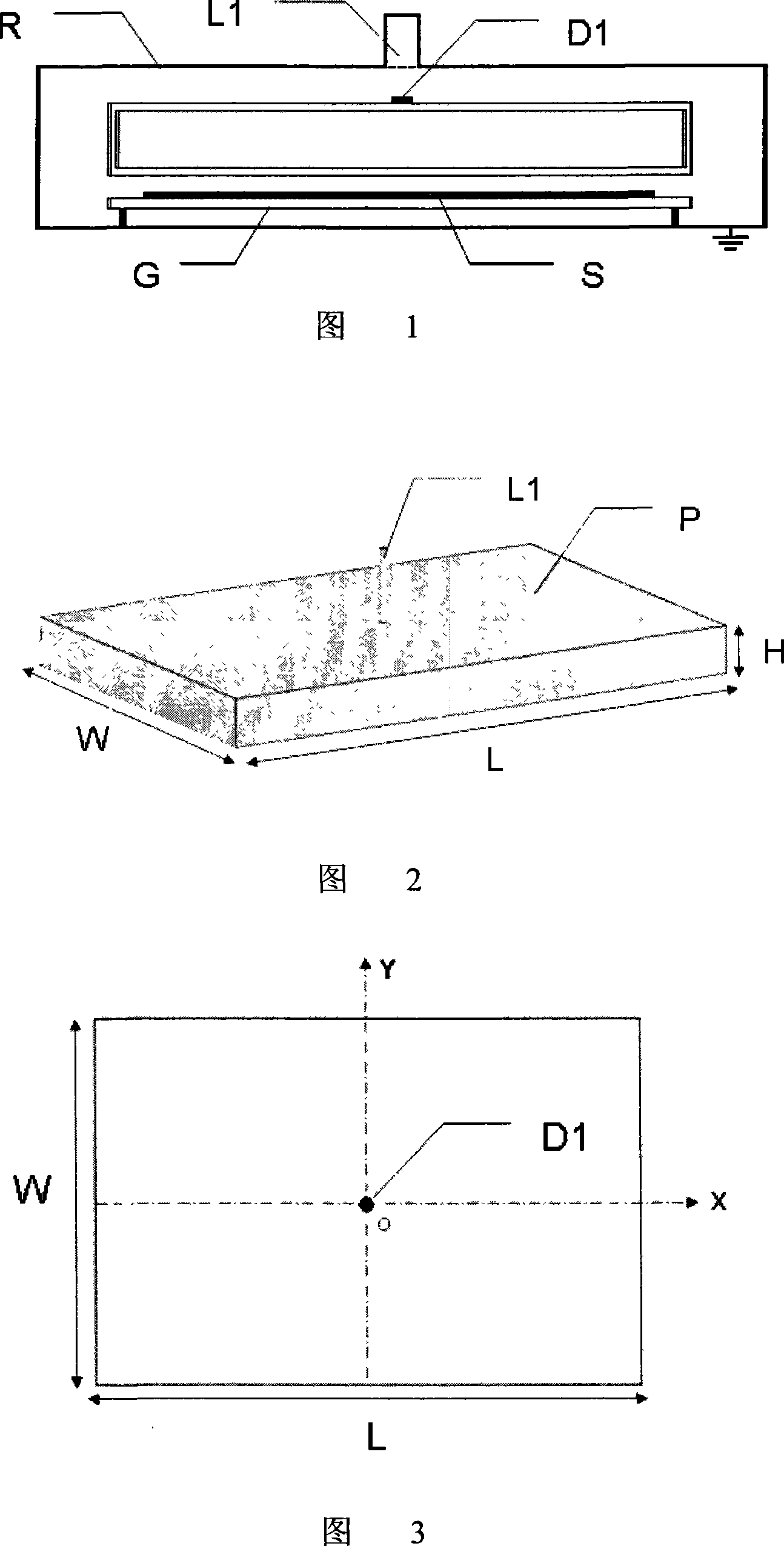

[0042] Back-fed parallel plate electrode single-point central power feed structure (as shown in Figure 2)

[0043] In this example, the rectangular parallel plate electrode has a length L=120cm, a width W=80cm, and a height H=10cm. The rear-side single-point feeding is adopted, and the electrode structure is shown in FIG. 1 of the embodiment. The position of the power feed-in point is shown in Figure 3, and the feed-in point D1 is located in the center of the x-y plane. The PECVD reaction chamber with the back-fed parallel plate electrode structure designed in this example is applied with a 40.68MHz excitation frequency power supply. The theoretical calculation results of the electric field distribution between the electrodes are shown in Figure 4, and the electric field non-uniformity is within ±4%. .

Embodiment 2

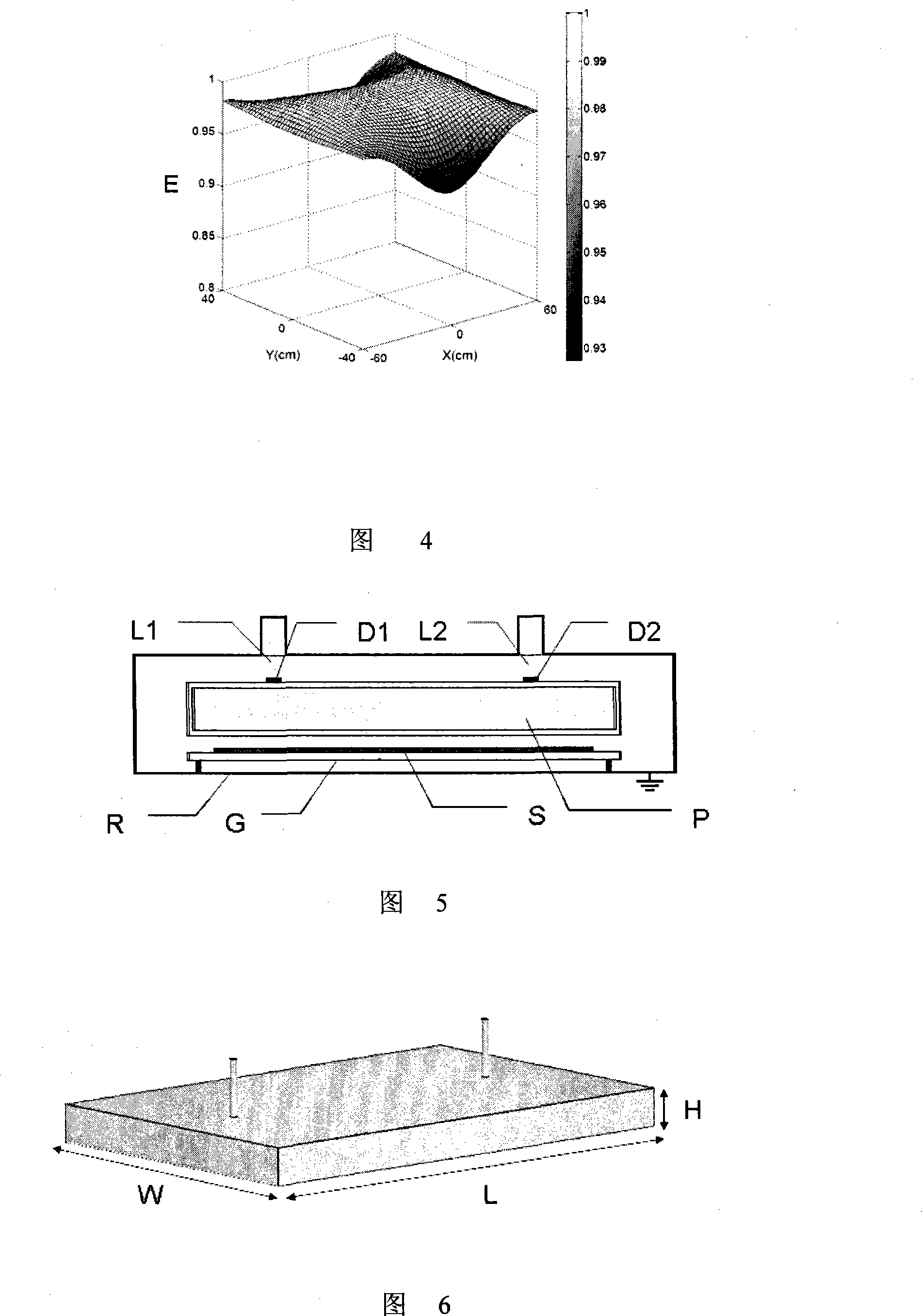

[0045] Two-point Power Feed-in (I) Structure of Back-fed Parallel Plate Electrodes

[0046] In this example, the rectangular parallel plate electrode has a length L=120cm, a width W=80cm, and a height H=10cm. The rear-side two-point feeding is adopted. The electrode structure is shown in Figure 6. The position of the power feed-in point is shown in Figure 7, and the x-y plane Cartesian coordinates of the feed-in points D1 and D2 are (40cm, 0) and (-40cm, 0) respectively. The PECVD reaction chamber with the back-fed parallel plate electrode structure designed in this example is applied with a 40.68MHz excitation frequency power supply, and the two ends are fed in with equal phase and equal amplitude power. The theoretical calculation results of the electric field distribution between the electrodes are shown in Figure 8. , the electric field non-uniformity is within ±5%.

Embodiment 3

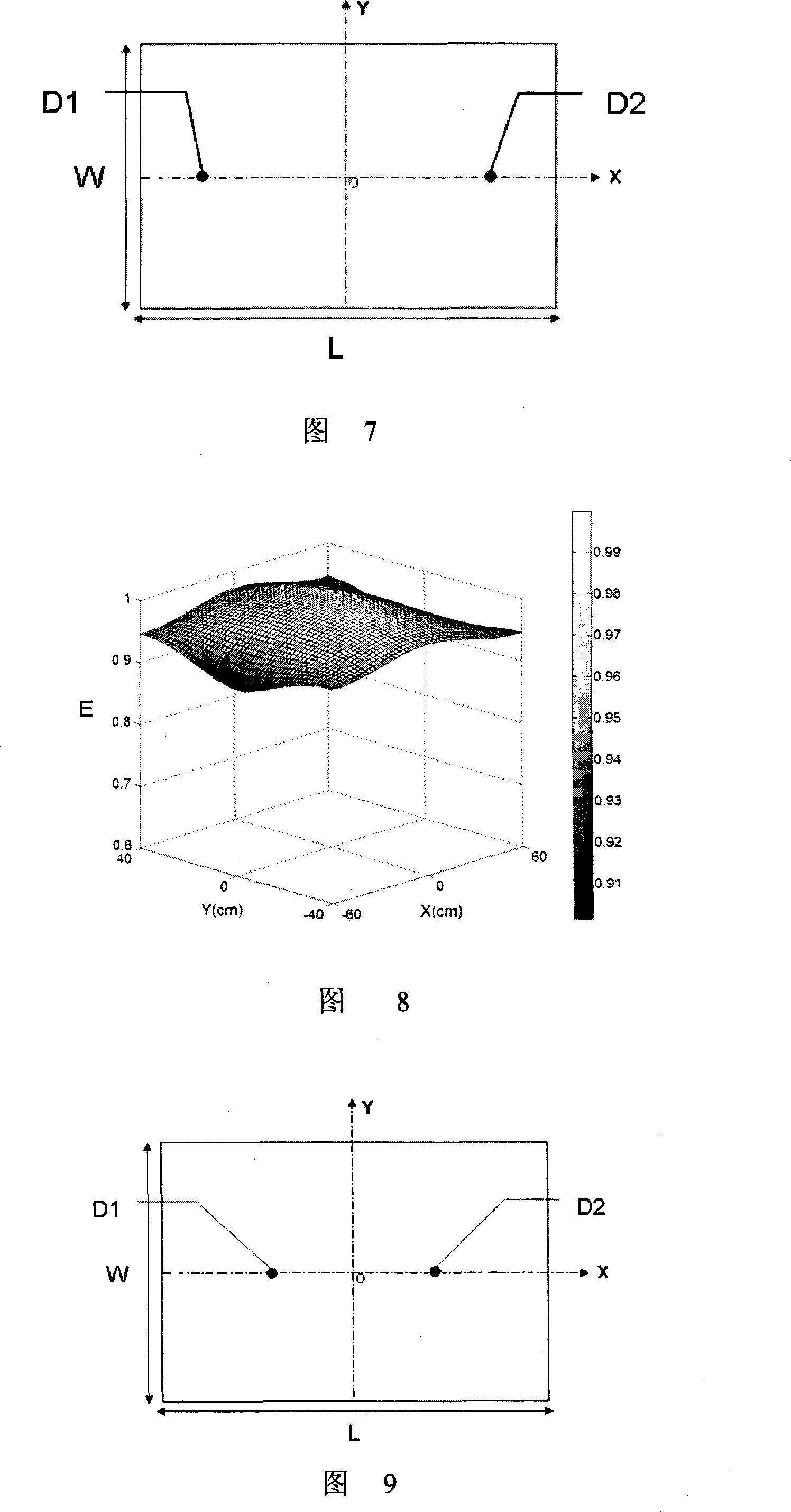

[0048] Back-feed parallel plate electrode two-point power feed (II) structure

[0049] In this example, the rectangular parallel plate electrode has a length L=120cm, a width W=80cm, and a height H=10cm. The rear-side two-point feeding is adopted. The electrode structure is shown in Figure 6. The position of the power feeding point is shown in Figure 9, and the x-y plane Cartesian coordinates of the feeding points D1 and D2 are (25cm, 0) and (-25cm, 0) respectively. The PECVD reaction chamber with the back-fed parallel plate electrode structure designed in this example is applied with excitation frequency power supplies of 40.68MHz and 54.24MHz respectively, and the two ends are fed in with equal phase and equal amplitude power. The theoretical calculation results of the electric field distribution between the electrodes are as follows: As shown in Figures 10 and 11, the electric field non-uniformity is within ±2.5% and ±4.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com