Method for producing bamboo dissolving pulp by pre-extracting hemicellulose and product thereof

A technology of hemicellulose and dissolving pulp, applied in the directions of spinning solution preparation, pulping with inorganic alkali, fiber raw material treatment, etc. Improve the reaction performance and its uniformity, considerable economic benefits, and strong targeted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

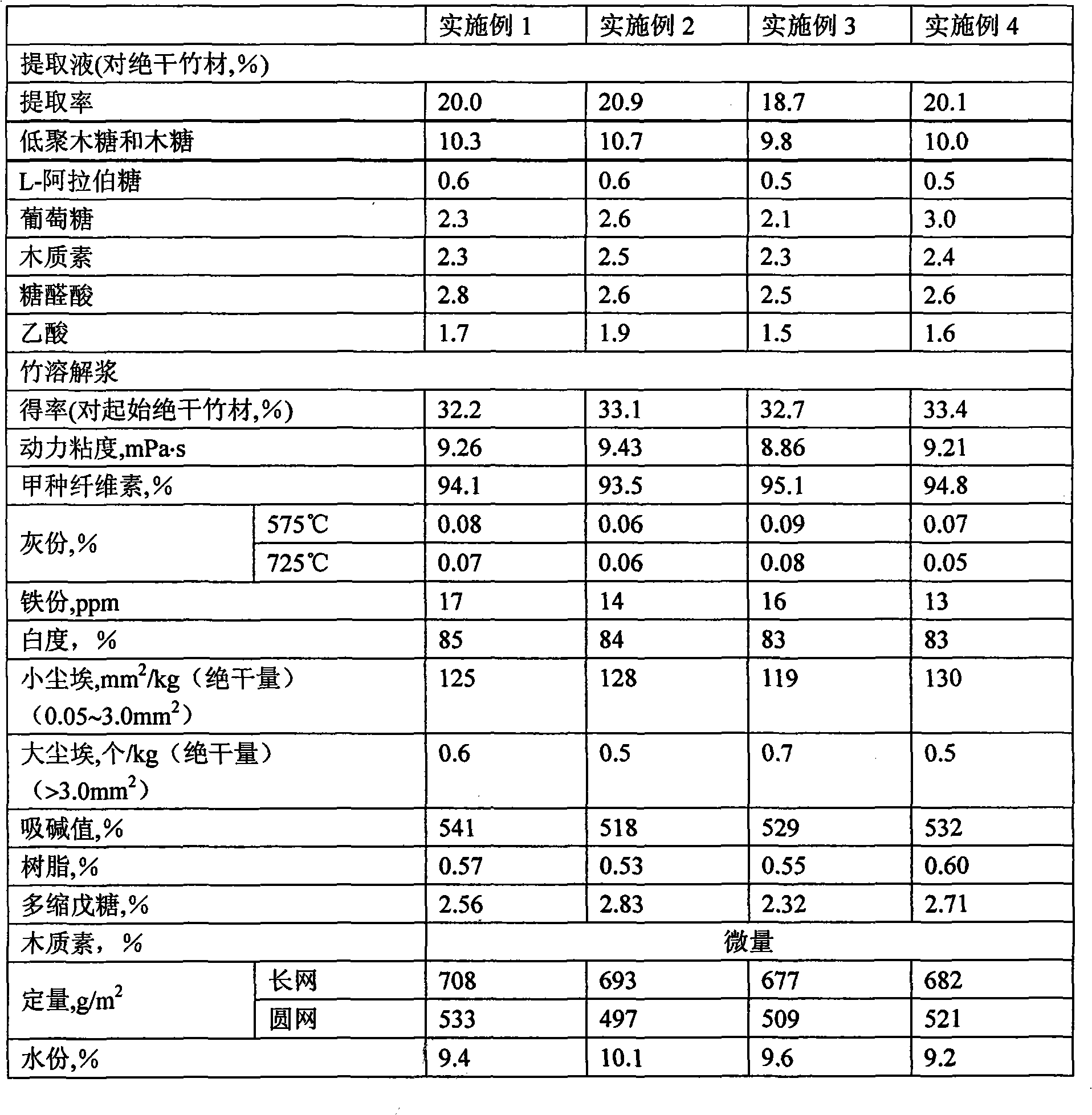

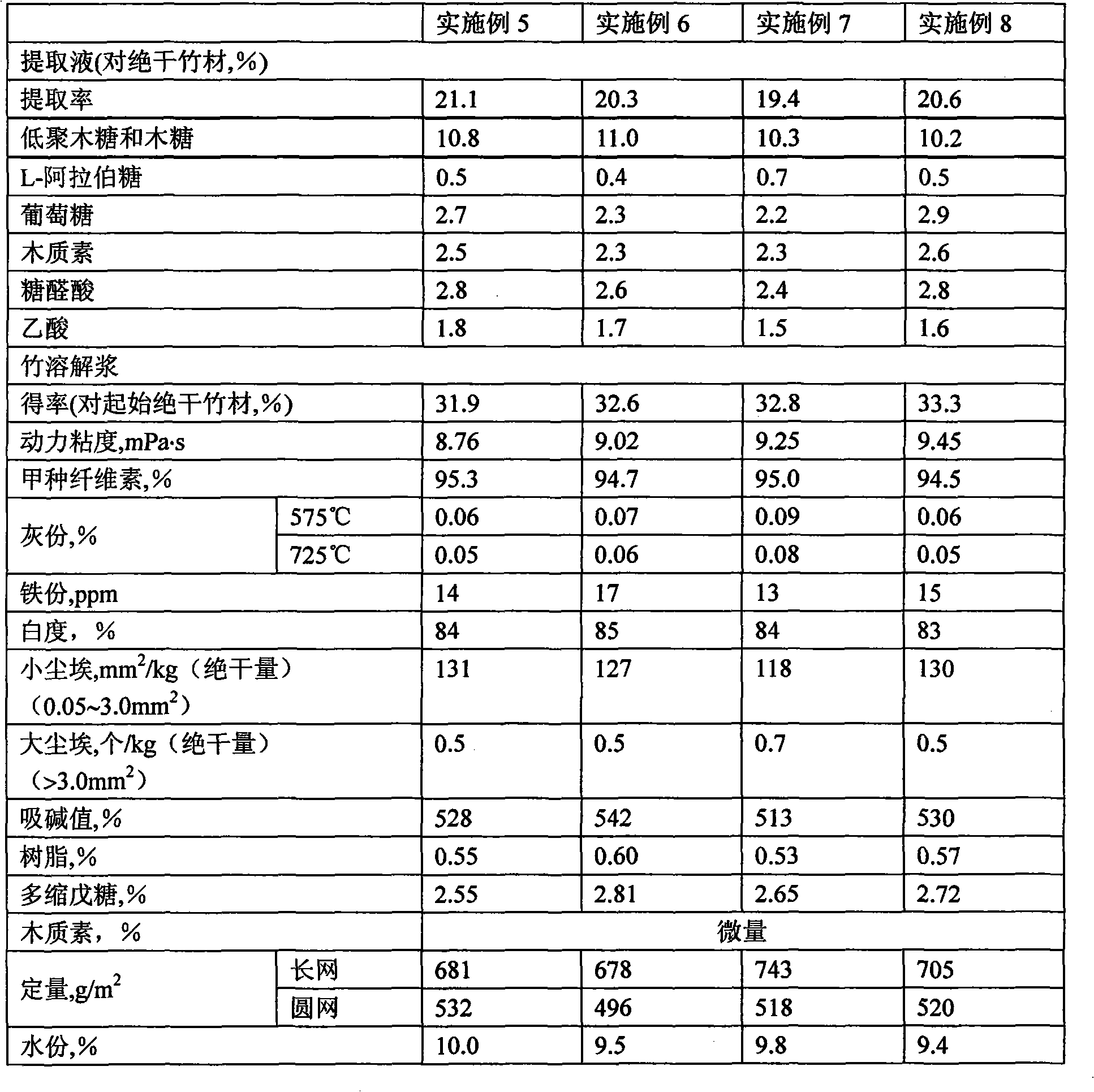

Examples

Embodiment 1

[0051] A kind of bamboo dissolving pulp pulping method of pre-extracting hemicellulose, comprises the steps:

[0052] (1) Bamboo material preparation: cut two to three-year-old bamboo into bamboo chips with a length of 15-30mm, a width of 10-20mm, and a thickness of 3-8mm through a slicer, screen through a high-frequency vibrating screen, and spray and wash with high-pressure water , remove impurities and dust;

[0053] (2) Pre-hydrolysis: carried out in a steaming ball, the process conditions are: the solid-liquid ratio is 1:3, the temperature is 150°C, the hydrolysis time is 220 minutes, and the pH value of the hydrolysis end point is 3-4;

[0054] (3) Liquid-solid separation and washing, collecting filtrate to obtain extract: use three-stage diafiltration to carry out liquid-solid separation and countercurrent washing on the hydrolyzate, first-stage direct diafiltration or washing and diafiltration with the last batch of second-stage filtrate , the second stage is washed a...

Embodiment 2

[0071] A kind of bamboo dissolving pulp pulping method of pre-extracting hemicellulose, comprises the steps:

[0072] (1) Bamboo material is prepared: with embodiment 1;

[0073] (2) Pre-hydrolysis: carried out in a vertical cooking pot, the process conditions are: the solid-liquid ratio is 1:3, the temperature is 170 ° C, the hydrolysis time is 110 minutes, and the pH value of the hydrolysis end point is 3 to 4;

[0074] (3) Liquid-solid separation and washing, collecting the filtrate to obtain the extract: same as in Example 1;

[0075] (4) The preparation of dissolving pulp by the residue alkali method comprises the following steps in sequence:

[0076] A. Cooking: Carry out in a vertical cooking pot, the process conditions are: the amount of alkali used is 18 to 26% (NaOH, to the initial dry bamboo), the solid-to-liquid ratio is 1: 2.0 to 3.7, and the total heating time is 150 ~240 minutes, the number of small steam releases is ≥2, the first holding temperature is 130~14...

Embodiment 3

[0079] A kind of bamboo dissolving pulp pulping method of pre-extracting hemicellulose, comprises the steps:

[0080] (1) Bamboo material is prepared: with embodiment 1;

[0081] (2) Pre-hydrolysis: carried out in a steaming ball, the process conditions are: the solid-liquid ratio is 1:5, the temperature is 150°C, the hydrolysis time is 240 minutes, and the pH value of the hydrolysis end point is 3-4;

[0082] (3) Liquid-solid separation and washing, collecting the filtrate to obtain the extract: same as in Example 1;

[0083] (4) Preparation of dissolving pulp by residual alkali method: same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com