Loess high fill in hill removing and gully filling projects and construction method of loess high fill

A loess high filling and engineering technology, applied in filling, foundation structure engineering, soil protection and other directions, can solve problems such as uneven settlement of foundations, slope deformation and damage, improve physical and mechanical properties, enhance earthquake resistance and vibration resistance Performance, the effect of solving poor drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

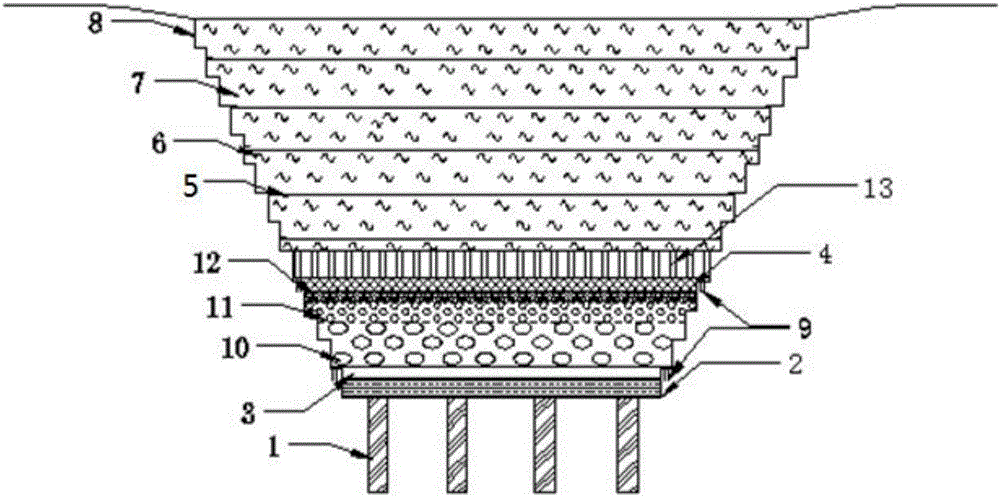

[0036]Embodiment 1 of the present invention provides a kind of loess high fill in the project of moving mountains and ditch filling. The high fill is composed of lime pile composite base, crushed stone drainage layer and loess layer from bottom to top; the lime pile composite base includes lime piles 1 and the lime soil cushion 2 above the lime pile 1; the gravel drainage layer is composed of composite geomembrane 3, gravel layer and three-dimensional composite drainage network 4 from bottom to top; the loess layer is composed of compacted loess layer 13 and reinforced loess The layer 7 is composed of layers from bottom to top. The reinforced loess layer 7 is evenly doped with glass fiber 6, and the reinforced loess layer 7 is laid with multi-layer bidirectional geogrids 5. Specifically, the diameter of the lime pile 1, the distance between the piles and The depth should be determined according to the pre-calculation of the load of the upper composite filling body and the beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com