Lightweight and porous construction materials containing rubber

a construction material and porous technology, applied in the field of cementitious construction materials, can solve the problems of affecting the construction efficiency of cementitious structures, the lightweight and granular nature of ground rubber crumbs, and the relatively high production cost of adhesive or latex compounds,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

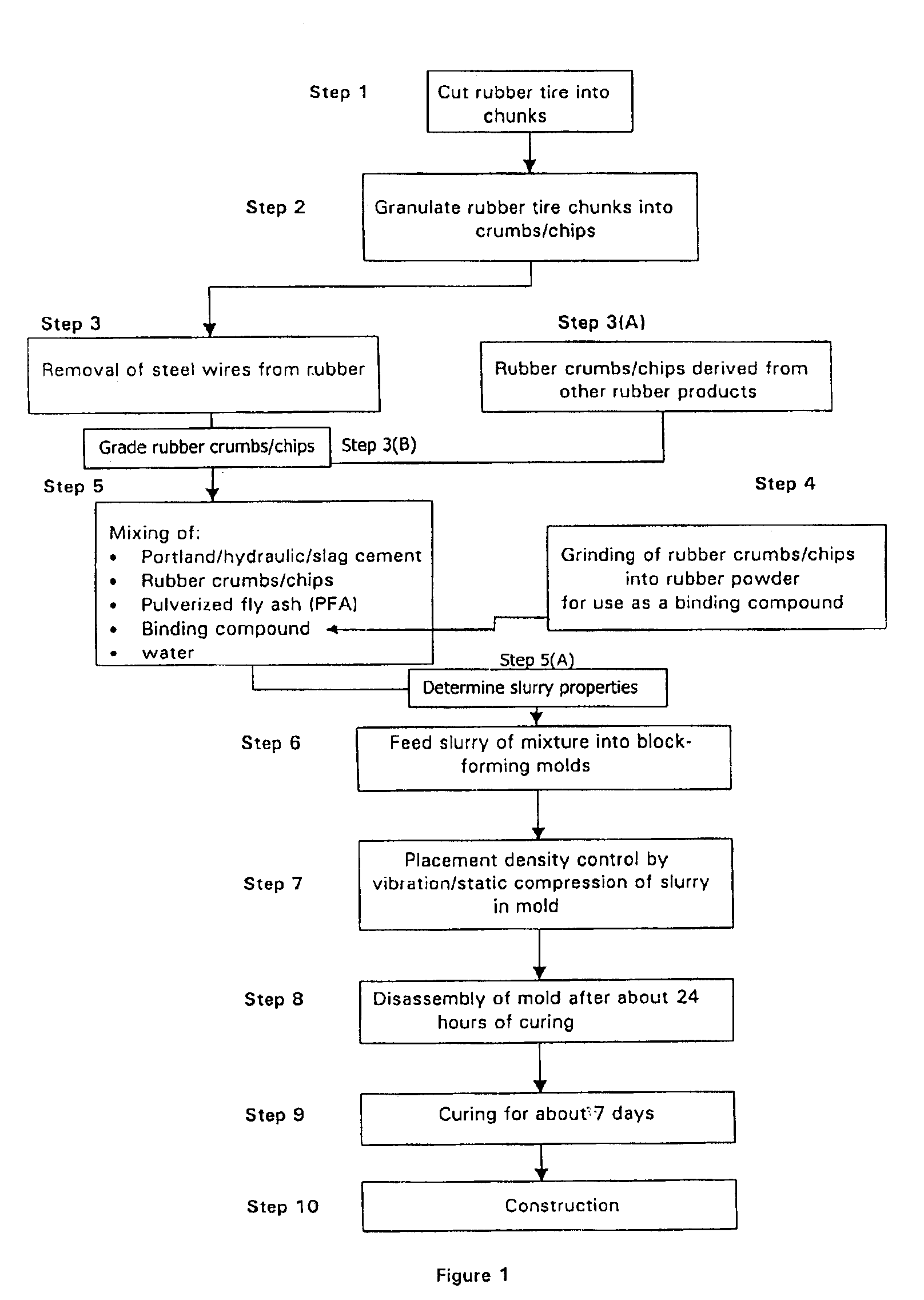

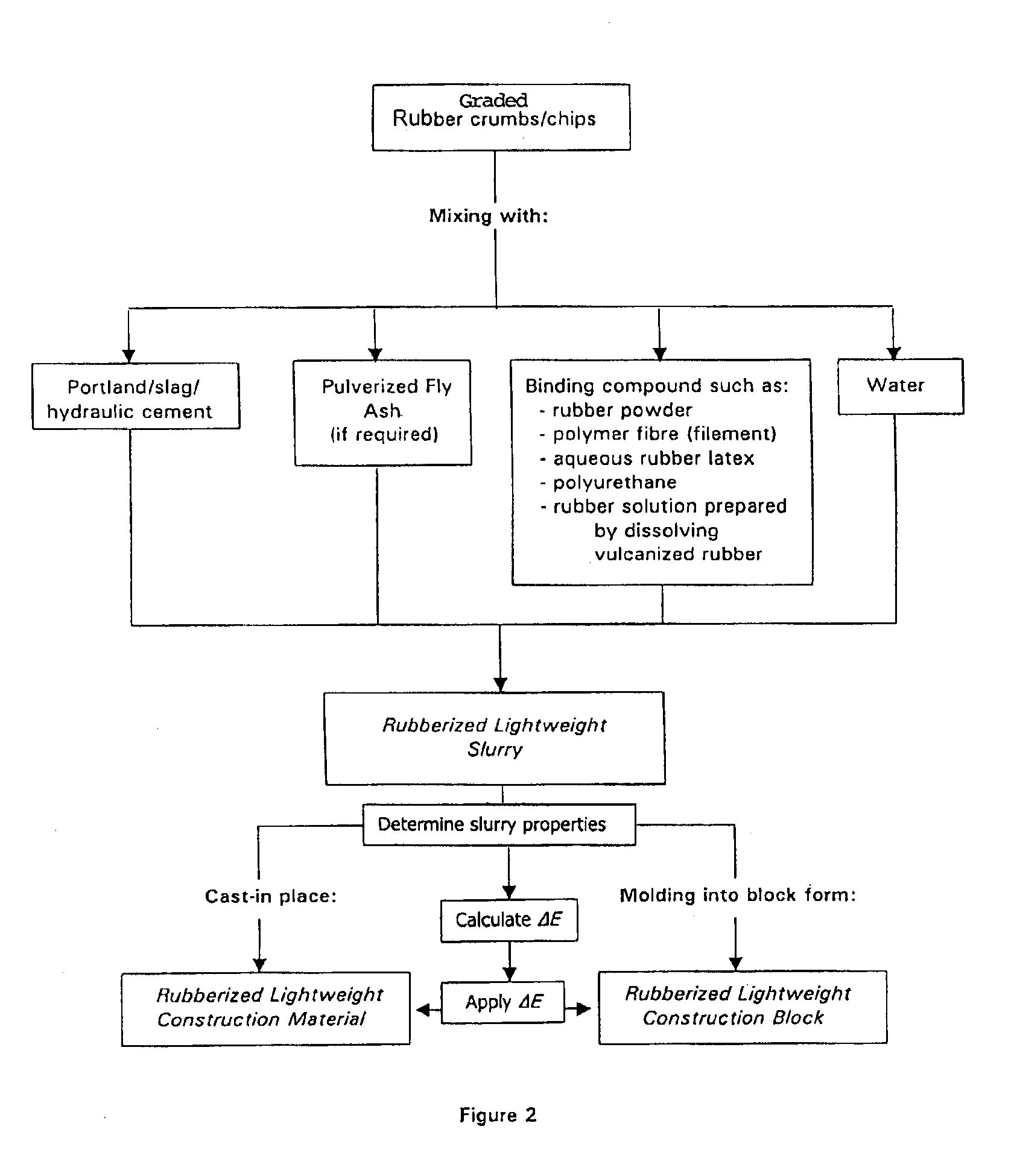

Method used

Image

Examples

Embodiment Construction

In broader terms, the present invention provides a process for manufacturing a construction material, comprising mixing a cementitious material, rubber bits and water and curing the mixture to form a porous matrix with interconnected pore spaces in which the rubber bits are bonded together by the cementitious material. In general, the bonding between the rubber bits is mainly achieved by the hardened cementitious material (cement gel). The resulting rubberized construction material has a lightweight and porous structure which has long-term chemically and mechanically stable constituents which allow it to be used for normal applications in civil and geotechnical works. The reduction in weight of the rubberized construction material over conventional materials has the advantage of greatly reducing the structural design loads and / or earth pressures where it is employed. The porous nature of the rubberized construction material is also advantageous as it allows free drainage of water an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| void ratio | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com