Dry heaping and wet discharging combined tailing heaping and discharging method

A dry tailings, combined technology, applied in separation methods, chemical instruments and methods, filling and other directions, can solve the problems of fine tailings dam difficulty and other problems, and achieve the effect of solving the problem of tailings stacking and discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

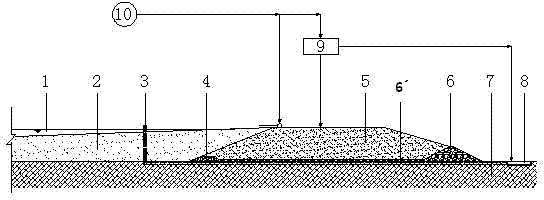

[0020] In order to further describe the present invention, a tailings stacking method of the present invention combining dry stacking and wet stacking will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0021] When choosing a dump site, the site selection principles are basically the same as those for tailings ponds. Select a reasonable dry tailings dam site according to the terrain and geological conditions of the dumping site, and lay out the dam foundation 7, flood drainage system 3, tailings slurry conveying system, and water return facilities. The concentration of the tailings discharged from the concentrator 10 is generally 20-30%. Part of the tailings enters the filter press dehydration workshop 9 to separate the tailings water from the dry tailings, and the dry tailings are transported to the top surface of the dry tailings dam body 5 for layered rolling and filling. The remaining wet tailings 2 are transported to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com