Coal mining subsidence area administration method for loess hilly-gully region

A gully area, loess technology, applied in the fields of botanical equipment and methods, filling, soil protection, etc., can solve problems such as the restoration of unfavorable surface ecological environment, the threat of underground safety production, and the unsatisfactory treatment effect. Restoration and restoration of the original soil ecological environment, the effect of high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

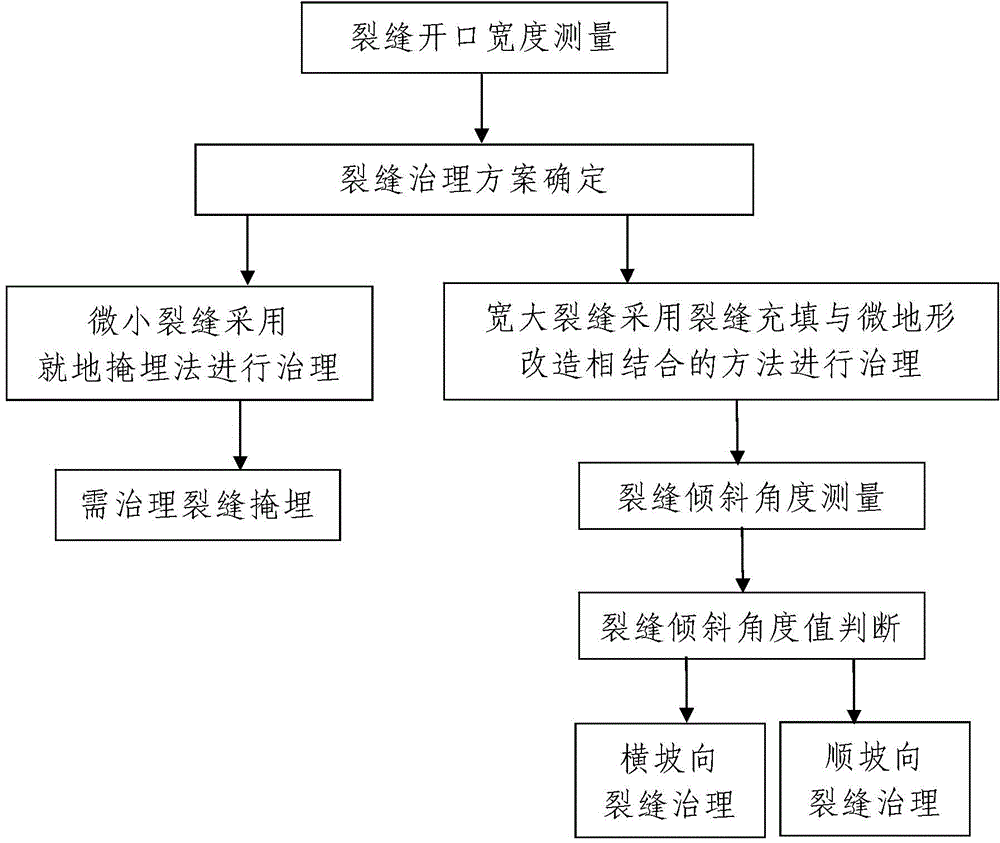

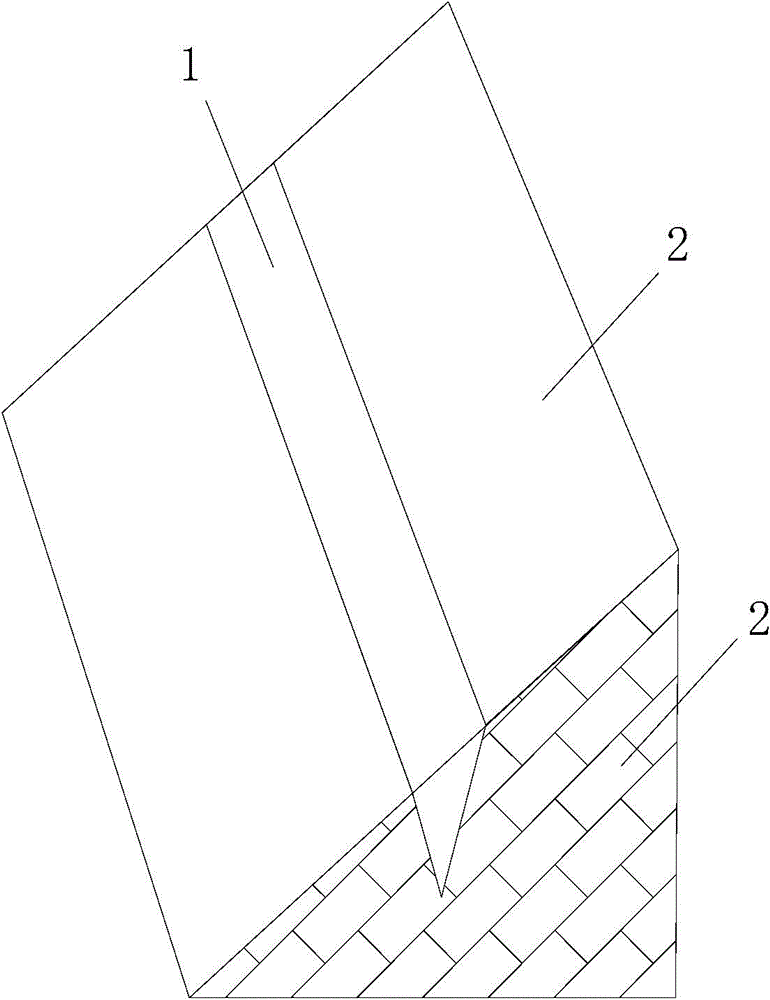

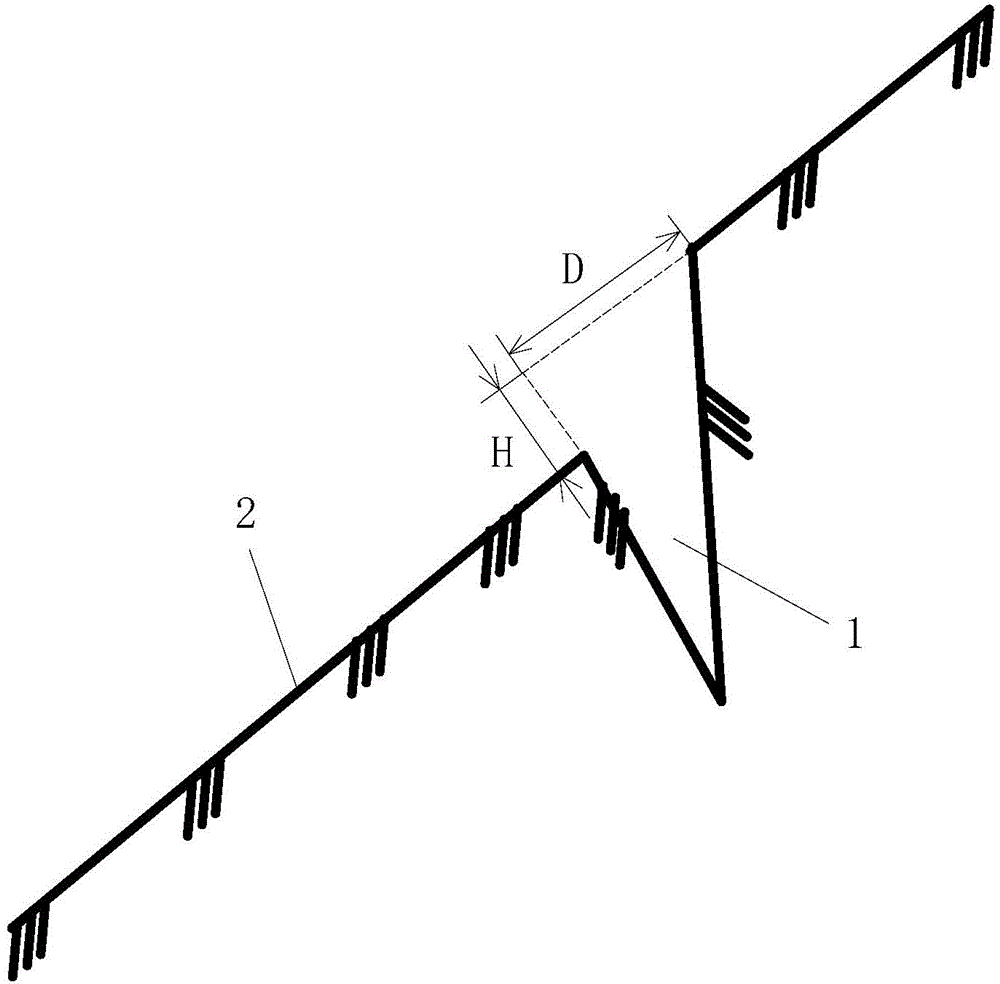

[0063] like figure 1 The method for treating coal mining subsidence in the loess hilly gully area shown is to control the collapse cracks 1 existing on the loess slope 2 of the controlled coal mining subsidence land respectively, and each collapse crack 1 on the loess slope 2 The treatment methods of 1 are the same; when any subsidence crack 1 is treated, the process is as follows:

[0064] Step 1. Measurement of crack opening width: measure the crack opening width D of the subsidence crack 1 currently being treated, and record the measurement results; the subsidence crack 1 currently being treated is a crack to be treated.

[0065] Step 2. Determination of the crack treatment plan: according to the crack opening width D of the crack to be treated measured in step 1, determine the treatment plan of the crack to be treated: when the crack opening width D≤10cm is obtained from the measurement , the fracture treatment scheme adopted is the in-situ burial method; when the measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com