Construction method of retaining wall by a prefabricated module panel geogrid reinforcement tailing sand

A technology of geogrid reinforcement and geogrid, applied in soil protection, filling, artificial islands, etc., can solve the problems of tailing sand that has not been retrieved, and there is no tailing sand, so as to reduce the damage of retaining wall and reduce the Hidden dangers of diseases and the effect of saving soil borrowing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

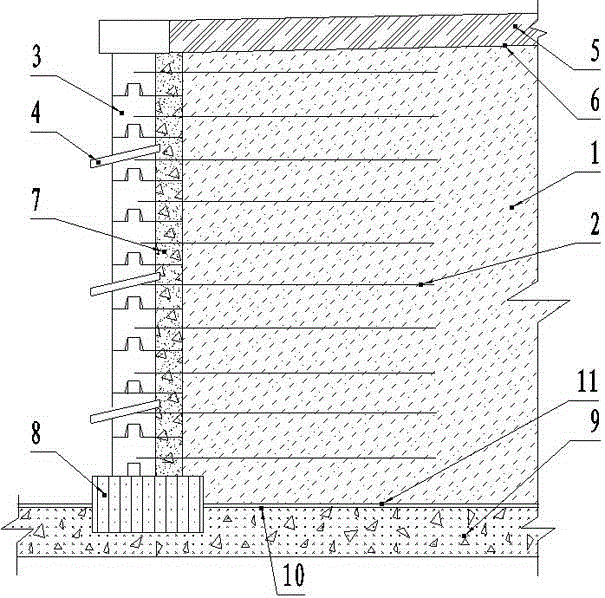

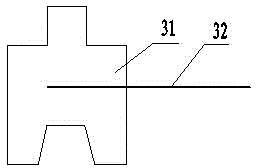

[0036] Such as figure 1 , 2A prefabricated modular panel geogrid-reinforced tailings sand retaining wall is shown, the bottom of which is a sand and gravel cushion 9, and the tailings sand filler 1 is laid on the top of the sand and gravel cushion 9, and in the sand and gravel cushion 9 on the outside of the retaining wall Reinforced concrete foundation 8 is poured on the upper part, sand and gravel cushion layer 9 extends to the outside of foundation 8, prefabricated concrete modular panels 3 are built on foundation 8, and first one-way geogrid 2 is set at intervals in tailings sand filler 1 as reinforcement materials, the first one-way geogrid 2 is connected with the second one-way geogrid 32 pre-buried in the prefabricated concrete module 31 through connecting rods, and the gravel filter layer 7 is laid between the panel 3 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com