Forging forming process of high barrel-shaped aluminum alloy forged piece

A forging forming and aluminum alloy technology, applied in the field of forging technology, can solve problems such as easy deformation of ring parts, local coarse grains, sensitivity to deformation temperature and deformation speed, etc., to prevent machining deformation, increase radial elongation, reduce anisotropic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of forging molding process of tall cylindrical aluminum alloy forging comprises the following steps:

[0035] The first step: blanking: use cast aluminum rod as the blank, the diameter of the blank is 680mm, and the height is 1400mm;

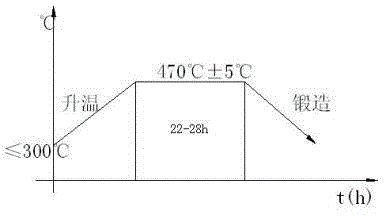

[0036] The second step: heating before forging: the first heating stage: place the billet in the heating furnace, and raise the temperature of the billet to 290°C; the second heating stage: continue to heat the The steel billet was heated to 465°C and held for 22 hours. The temperature curve of heating before forging is as follows: figure 1 shown.

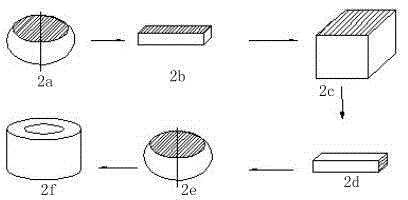

[0037] The third step: billet making: such as figure 2 As shown, the first stage: use the cross upsetting method to upset the heated billet to form a round cake; the specific upsetting method of the cross upsetting method is as follows: first, the billet is upset along the Z axis to form a disc, and the shape of the disc 1000mm in diameter and 650mm in height ( fig...

Embodiment 2

[0047] A kind of forging molding process of tall cylindrical aluminum alloy forging comprises the following steps:

[0048] The first step: blanking: use the cast aluminum rod as the blank, the diameter of the blank is 680mm, the height is 1500mm, and the weight is 1550kg.

[0049] The second step: heating before forging: the first heating stage: place the billet in the heating furnace, and raise the temperature of the billet to 300°C; the second heating stage: continue to heat the The steel billet was heated to 475°C and held for 28 hours. The temperature curve of heating before forging is as follows: figure 1 shown.

[0050] The third step: billet making: such as figure 2 As shown, the first stage: Upsetting the heated billet to form a round cake using the cross-upsetting method; the specific upsetting method of the cross-upsetting method is as follows: first, the billet is upset along the Z-axis to form a disc, and the diameter of the disc is is 1030mm a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com