Ti6242 titanium alloy and preparation method of small-size bar thereof

A titanium alloy, small-scale technology, applied in the field of non-ferrous metal processing, can solve the problems of poor uniformity of the bar structure, achieve the effect of good flaw detection, high uniformity of the structure, and overcome the technical bottleneck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

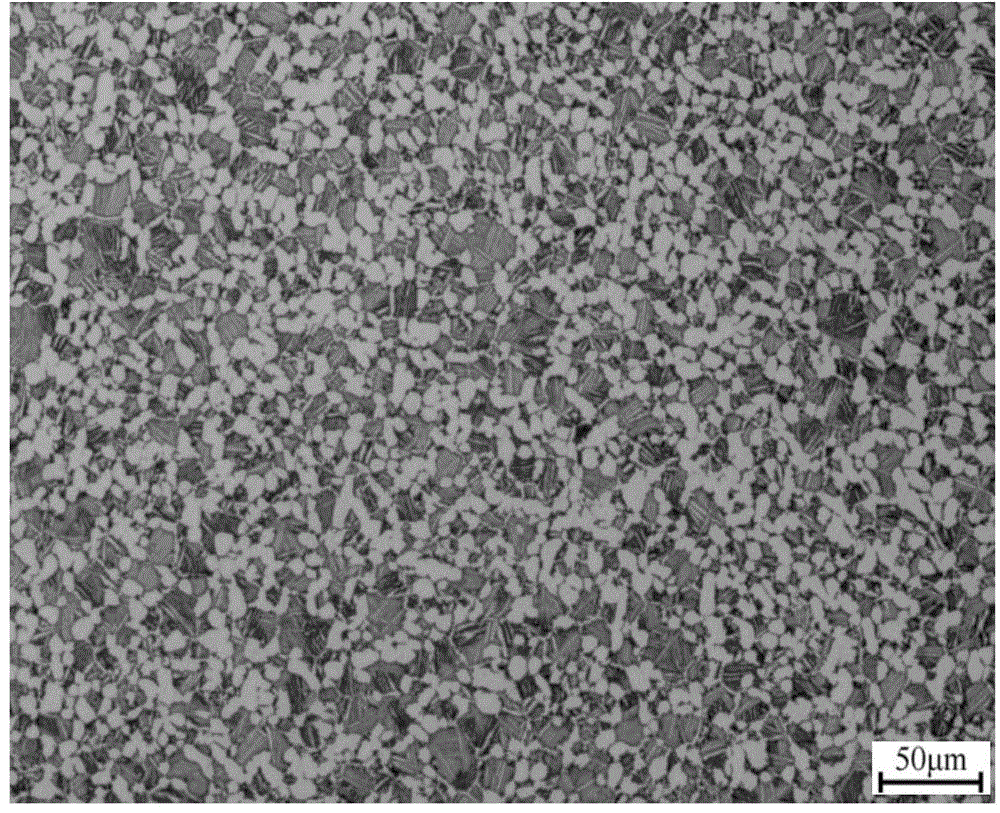

[0031] The preparation method of the above-mentioned Ti6242 titanium alloy small-size bar material specifically comprises the following steps:

[0032] Step 1: Blank Forging

[0033] The Ti6242 titanium alloy ingot is heated at 150°C-200°C above the phase transition point, the holding time is 240-480min, the forging ratio is controlled between 1.2-1.6 during forging, and the billet with the as-cast structure is initially broken; the Ti6242 titanium alloy ingot It is a 3-5 ton Ti6242 titanium alloy ingot produced by a vacuum consumable electric arc furnace. It is composed of the following components according to the mass percentage: Al 5.50%-6.50%, Sn 1.80%-2.20%, Zr 3.60%-4.40% , Mo 1.80%~2.20%, Si 0.06%~0.1%, Fe≤0.10%, O≤0.15%, C≤0.05%, N≤0.05%, the rest are titanium and unavoidable impurity elements;

[0034] Step 2: Intermediate billet forging

[0035] 7-fire forging the pre-broken as-cast structure blank obtained after billet forging in step 1, heating at 40°C below the ...

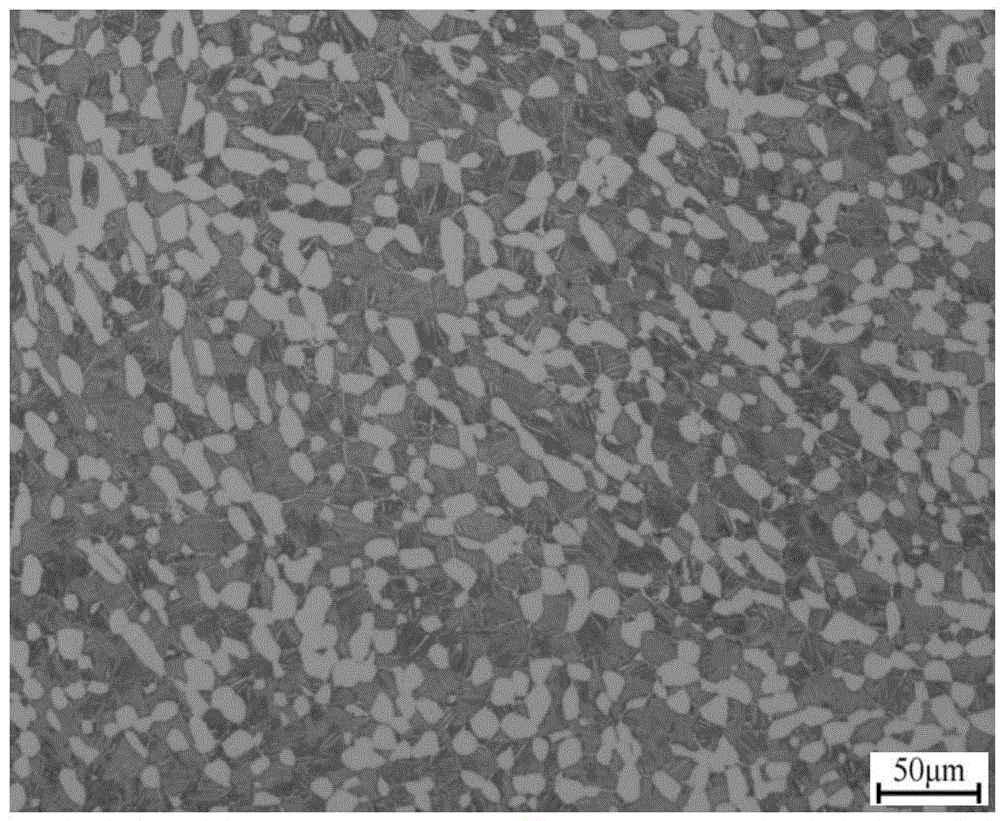

Embodiment 1

[0042] Open billet forging: Heating 3 tons of Ti6242 titanium alloy ingot at 1190°C, holding it for 240 minutes, performing one upsetting and one drawing, the forging ratio is controlled at about 1.4, and the final forging temperature is controlled above 950°C to avoid surface and core The temperature difference is large, resulting in uneven structure, and a billet with a preliminary broken structure in the as-cast state is obtained; among them, the Ti6242 titanium alloy ingot is composed of the following components according to the mass percentage: Al 5.50%, Sn 2.20%, Zr 4.0%, Mo 2.20%, Si 0.08%, Fe≤0.10%, O≤0.15%, C≤0.05%, N≤0.05%, the rest is titanium and unavoidable impurity elements;

[0043] Intermediate billet forging: 7-fire forging is carried out on the billet obtained with the preliminary broken cast structure. The heating temperature of 1 fire is 1100 ℃, after 3.5 hours of heat preservation, carry out two upsetting and two drawing; Upsetting and two pulls; 4 heatin...

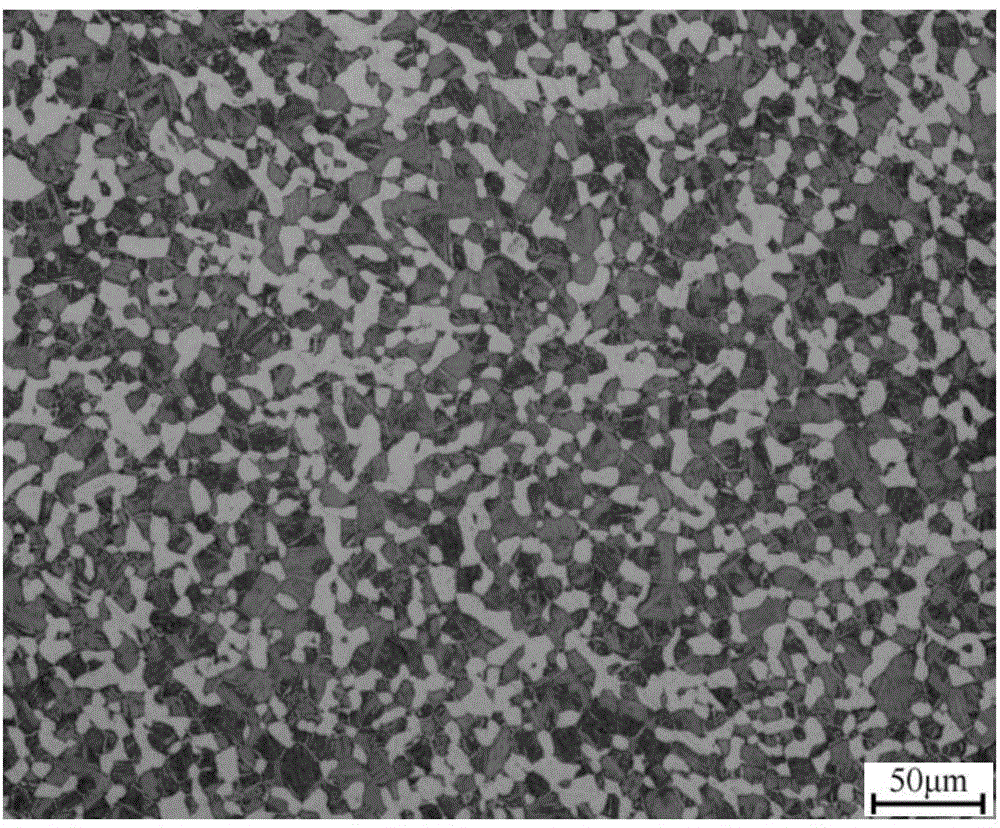

Embodiment 2

[0052] Blank forging: Heating the 4-ton Ti6242 titanium alloy ingot at 1170°C, holding it for 360 minutes, then performing one upsetting and one pulling, and the forging ratio is controlled at about 1.2. The final forging temperature is controlled above 950°C to avoid the large temperature difference between the surface and the core, resulting in uneven structure, and to obtain a billet with a preliminary broken structure in the as-cast state; among them, the Ti6242 titanium alloy ingot is composed of the following components according to the mass percentage: Al 6.50%, Sn 2.0%, Zr 3.60%, Mo 2.0%, Si 0.1%, Fe≤0.10%, O≤0.15%, C≤0.05%, N≤0.05%, the rest is titanium and unavoidable impurity elements;

[0053] Intermediate billet forging: 7-fire forging is carried out on the billet obtained with the preliminary broken cast structure. The heating temperature of the 1 fire is 1100 ℃, and two upsetting and two pulling are performed after the heat preservation for 7 hours; Upsetting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com