Preparation method of biological function composite auxetic hydrogel with shell core structure

A hydrogel and biological technology, applied in medical science, prosthesis, etc., can solve the problems of research reports, lack of clear understanding of auxetic properties and mechanism, and achieve the effect of enhancing cross-linking effect and controllable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] Step 1: Mix hyaluronic acid (HA) solid particles with deionized water to make a HA water-based suspension with a mass fraction of HA of 20%, put it into a pressure steam container and heat to dissolve, and the pressure in the container is maintained at 0.10 MPa , the temperature is 120°C, and the heating time is 1.5 hours. Then take out the homogeneously dissolved HA polymer sol, and let it stand for cooling.

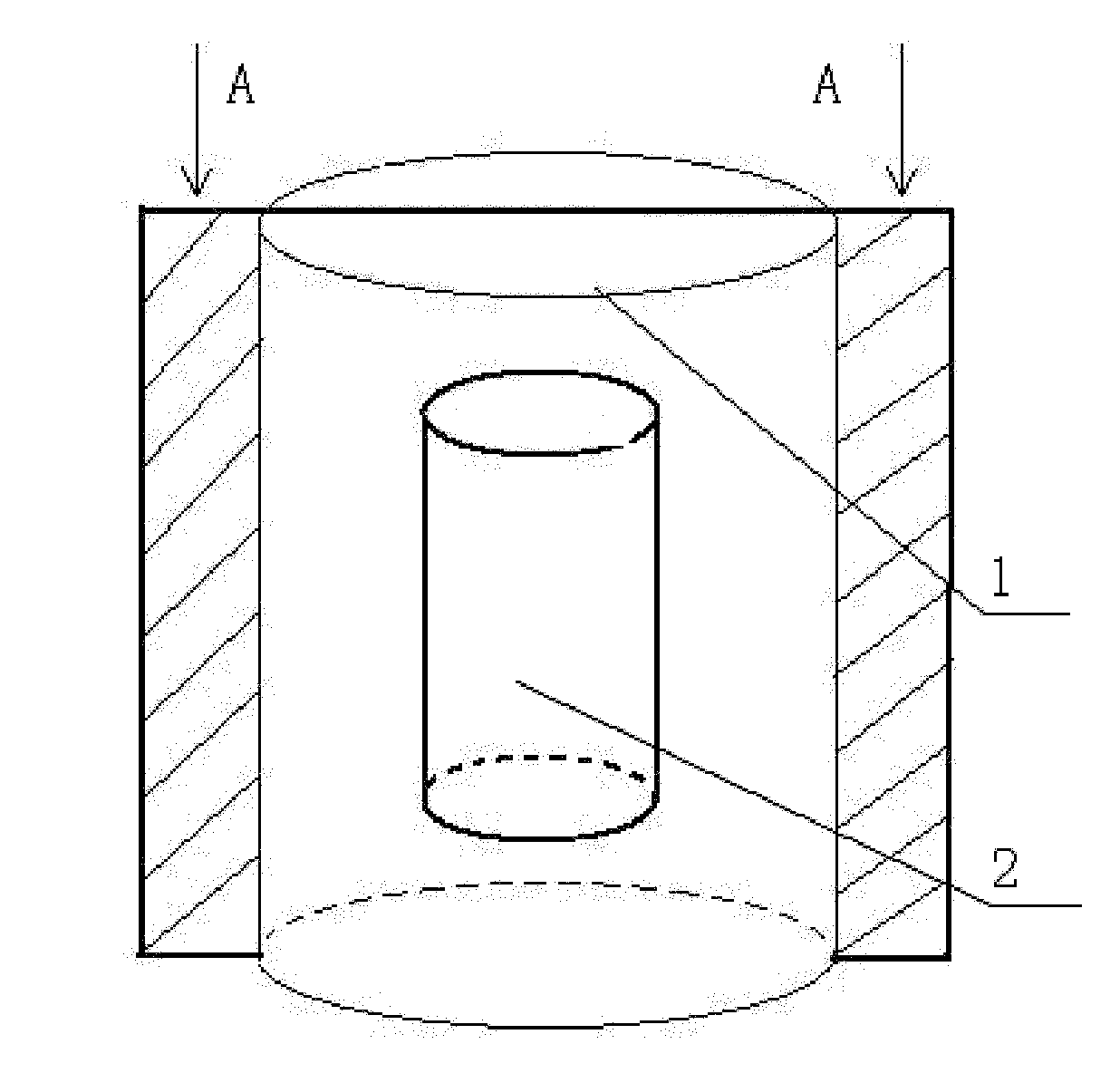

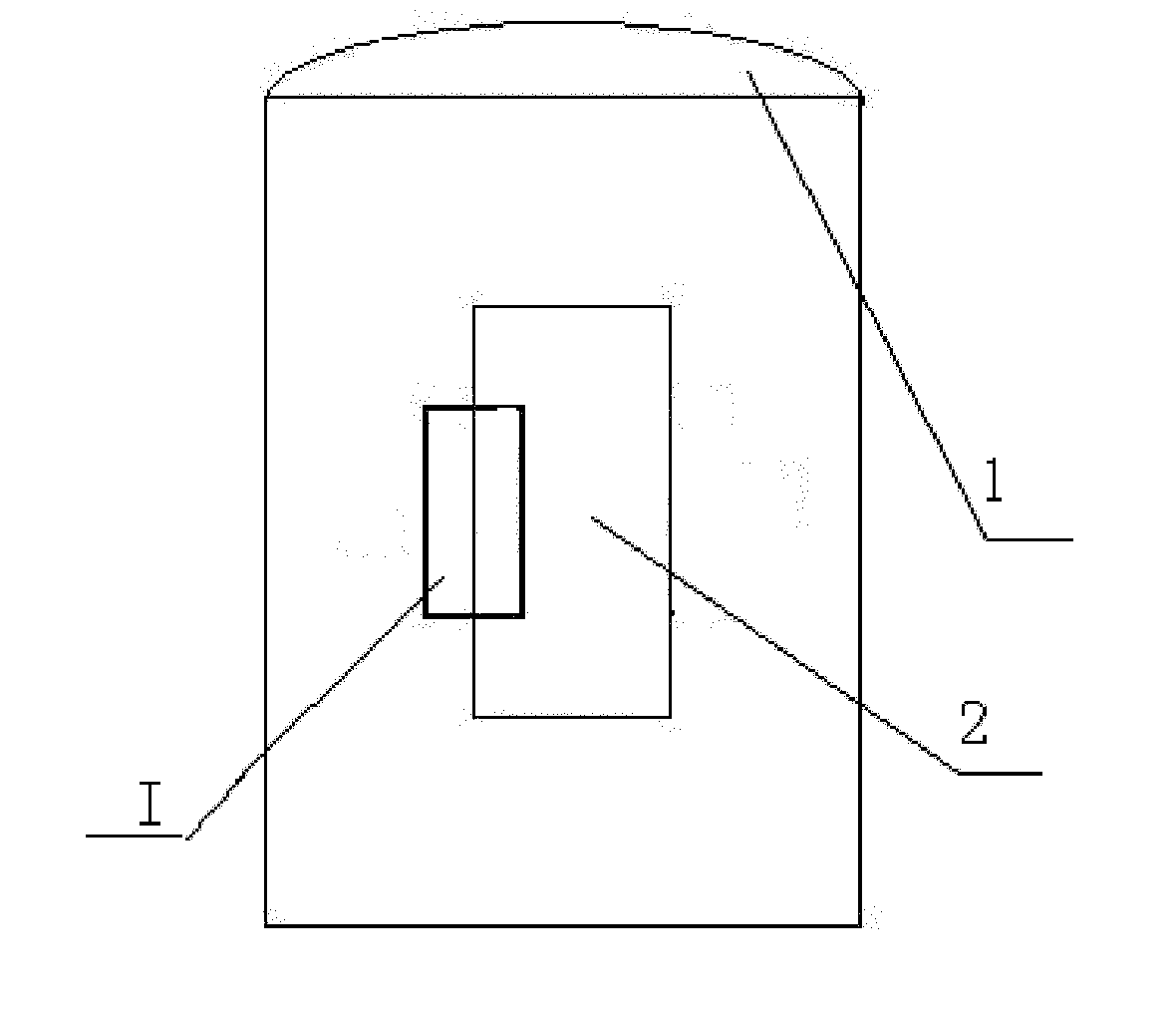

[0030] Step 2: Inject the above sol into a stainless steel cylindrical mold with an inner diameter of 10.00mm, and perform a freeze-thaw cycle treatment: freeze temperature -30°C, freeze time for 8 hours, and then thaw at room temperature for 8 hours, so freeze-thaw cycle 6 times, The core structure was cut into a cylinder with a height of 20.00 mm as the core, thereby obtaining the core structure of the biofunctional composite auxetic hydrogel with a shell-core structure.

[0031] Step 3: Weigh a certain amount of PVA solid particles and add them to deionized w...

example 2

[0034] Step 1: Add analytically pure polyvinylpyrrolidone (PVP) particles into deionized water to prepare a water-based suspension with a mass percentage of PVP of 25%, stir evenly in a constant temperature water bath at 60°C until the PVP dissolves, and let stand to cool. Obtain PVP polymer sol.

[0035] Step 2: inject the above-mentioned sol into a stainless steel cylinder mold with an inner diameter of 20.00 mm, and place it in a gamma ray radiation field for radiation treatment with a dose of 20 kGy to obtain a green body, which is cut into a cylinder with a height of 20.00 mm as core body, thereby obtaining the core body structure of the biofunctional composite auxetic hydrogel having a shell-core structure.

[0036] Step 3: Weigh a certain amount of PVP solid particles and add them to deionized water to prepare a water-based suspension with a mass fraction of 15%. After stirring to make it fully mixed, stir in a constant temperature water bath at 90°C until the PVP solid p...

example 3

[0039] Step 1: Mix polyvinyl alcohol (PVA) solid particles with deionized water to make a PVA water-based suspension with a PVA mass fraction of 35%, put it into a pressure steam container and heat to dissolve, and the pressure in the container is maintained at 0.15 MPa , the temperature was 110°C, and the heating time was 2 hours. Then the homogeneously dissolved PVA polymer sol is taken out and allowed to stand for cooling.

[0040] Step 2: Inject the above-mentioned sol into a stainless steel cylinder mold with an inner diameter of 20.00mm, and perform freeze-thaw cycle treatment: freeze temperature -20°C, freeze time for 10 hours, and then thaw at room temperature for 10 hours, so freeze-thaw cycle 8 times, The core structure was cut into a cylinder with a height of 25.00 mm as the core, thereby obtaining the core structure of the biofunctional composite auxetic hydrogel with a shell-core structure.

[0041] Step 3: Weigh a certain amount of PVA solid particles and add th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com