Model prediction tracking control method in batch chemical engineering

A chemical process and model prediction technology, applied in the field of automation, can solve problems such as low device efficiency, high product specifications and quality, and unsatisfactory control accuracy and stability, so as to improve accuracy, improve control stability, improve tracking performance and The effect of anti-interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Take the injection molding process as an example:

[0079] Here we take the pressure-holding control in the injection molding process as an example to describe, and the adjustment method is to control the valve opening of the proportional valve.

[0080] Step 1. Establish the input and output model of the pressure holding control, the specific method is:

[0081] 1.1 First collect the input and output data of the pressure-holding control process, and use the data to establish the model of the pressure-holding control process, in the form as follows:

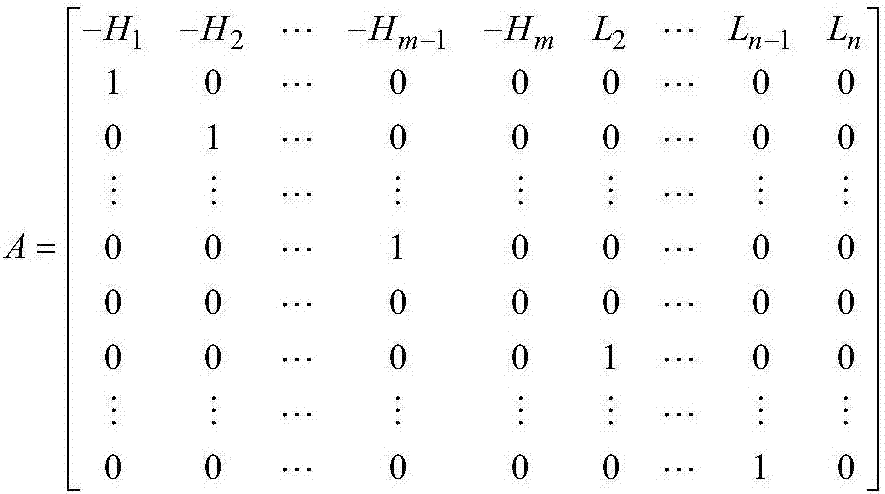

[0082] A(q t -1 )y(t,k)=B(q t -1 )u(t,k)

[0083] A(q t -1 )=1+H 1 q t -1 +H 2 q t -2 +…+H m q t -m

[0084] B(q t -1 ) = L 1 q t -1 +L 2 q t -2 +…+L n q t -n

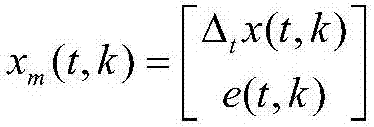

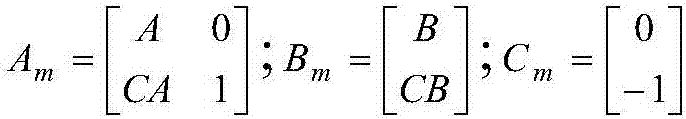

[0085] Where t and k are the discrete time and cycle index respectively, y(t,k) and u(t,k) are the holding pressure control pressure and valve opening at time t in the k cycle, q t -1 ...q t -m ,q t -1 ...q t -n They are operato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com