Composite yarn formation method of built-in powder materials

A powder material and powder technology, applied in the textile field, can solve the problems of high frequency of woven warp yarn breakage, poor product quality and inability to clean, and achieve the effect of omitting spun yarn drafting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

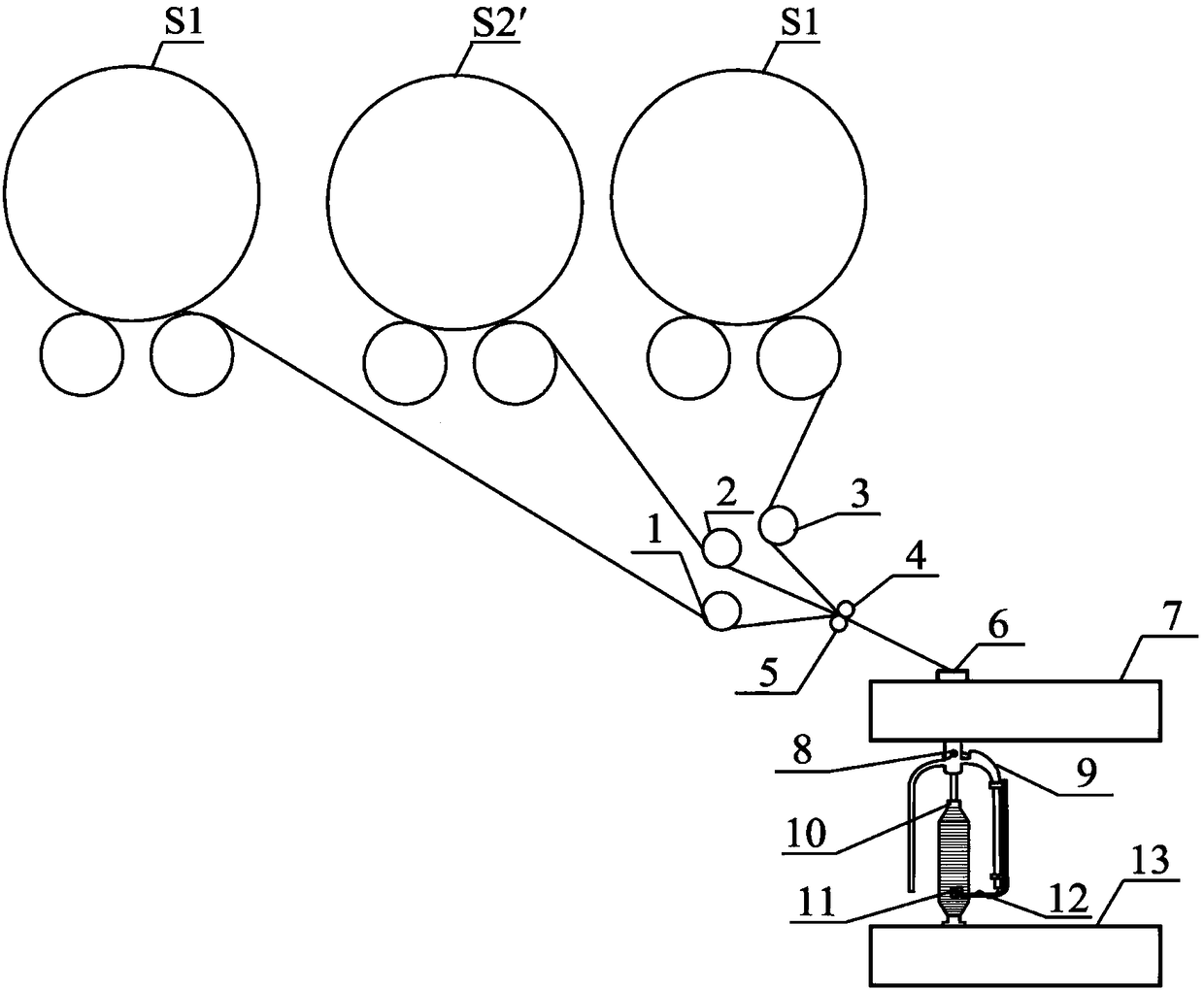

[0020] A. Preparation of fiber strips

[0021] The non-woven flexible surface material roll with an area density of 2-100 g / m2 is installed on a cutting machine, and the non-woven surface material is cut into fiber strips S 1 and threads with a linear density of 10-800 g / km The fiber strip S2 with a density of 4-200 g / km, the fiber strip S1 and the fiber strip S2 are respectively wound on the bobbin. The characteristics of the flexible surface material, the non-woven flexible surface material is directly and accurately and evenly cut into fiber strips, in essence, a flexible prepolymer of strip-shaped fibers is quickly made, which is used for the subsequent padding processing and compounding of the fiber strips. Fully prepared for twisting and forming yarns, breaking the technical bottleneck of traditional carding and collecting of textile fibers into slivers, eliminating the need for multiple drafting and drawing in pre-spinning of traditional spinning, drawing and twisting o...

Embodiment 1

[0027] Example 1. Yarn forming with built-in graphene fragment powder

[0028] The selected powder is graphene fragment powder, and the particle size distribution of graphene fragment powder is 10-100 nanometers, which is a solid particle material in an intermediate state between atoms, molecules and macroscopic objects. Graphene has excellent electrical properties and light absorption properties, and can be used to develop products such as sensors, high-density magnetic recording, and wave-absorbing stealth components, and is widely used in medical testing, military stealth, and other fields; , the traditional coating and built-in packing method are used to directly compound with textiles, which cannot guarantee the uniform dispersion and arrangement of graphene fragment powder and the combination of stability and durability, resulting in a decrease in the efficiency of sensing, electrical conductivity, and wave absorption, and it is easy to fall off. It can be cut and proces...

Embodiment 2

[0035] Embodiment 2. Composite yarn forming with built-in activated carbon powder

[0036] The selected activated carbon powder has a particle size of 800-1000 microns. The activated carbon powder is rich in nano-microporous structure and is widely used in air filtration, formaldehyde adsorption, water filtration and other fields. However, it is difficult for activated carbon powder to be compounded into yarn. Coating, built-in packing and textile compounding cannot guarantee the uniform dispersion and stable combination of activated carbon powder, resulting in a decrease in the efficiency of adsorption and filtration functions, and it is easy to fall off and difficult to be cut and processed arbitrarily. In order to solve this technical problem, adopt the present invention to carry out the composite yarn forming method of built-in activated carbon powder, concrete steps are:

[0037] A. Preparation of fiber strips

[0038] The polypropylene non-woven flexible surface materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com