Method for refining grains of heavy forging steel of nuclear reactor evaporator

A technology of grain refinement and nuclear reactor, which is applied in furnace types, furnaces, electric furnaces, etc., can solve the problems that large forgings are difficult to meet performance requirements, and achieve the effects of high strength, grain refinement, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

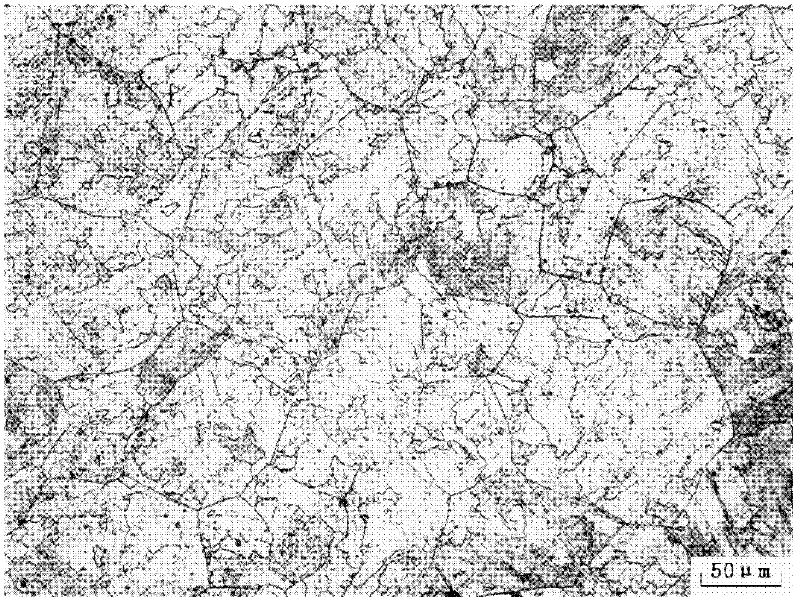

[0029] The improved vacuum carbon deoxidation process is used to smelt test steel. The molten steel is treated with aluminum after vacuum treatment and before pouring. The mass fraction of aluminum element is controlled to be 0.02-0.04%, and the mass fraction of nitrogen element is 0.005-0.015%. Because vacuum carbon deoxidation is used, Therefore, the mass fraction of silicon element is figure 2 . The same batch of samples were subjected to quenching and tempering treatment and simulated post-weld stress relief heat treatment, and processed into tensile and impact samples conforming to national standards for mechanical performance tests. The test results are shown in Table 4. Experimental results show that the present invention obtains a fine grain size (<20 μm), and at the same time, obtains good comprehensive mechanical properties, especially impact toughness. In the heat treatment furnace of the heat treatment process of the present invention, the temperature control accu...

Embodiment example 2

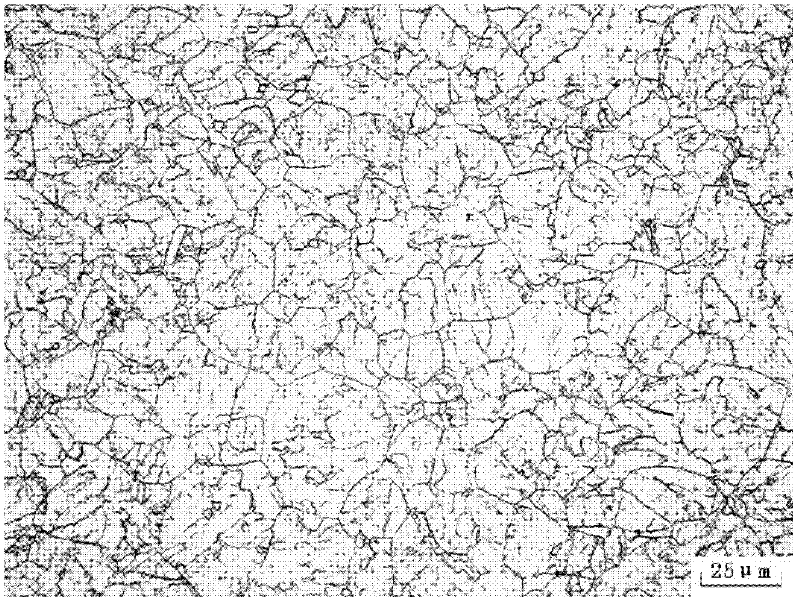

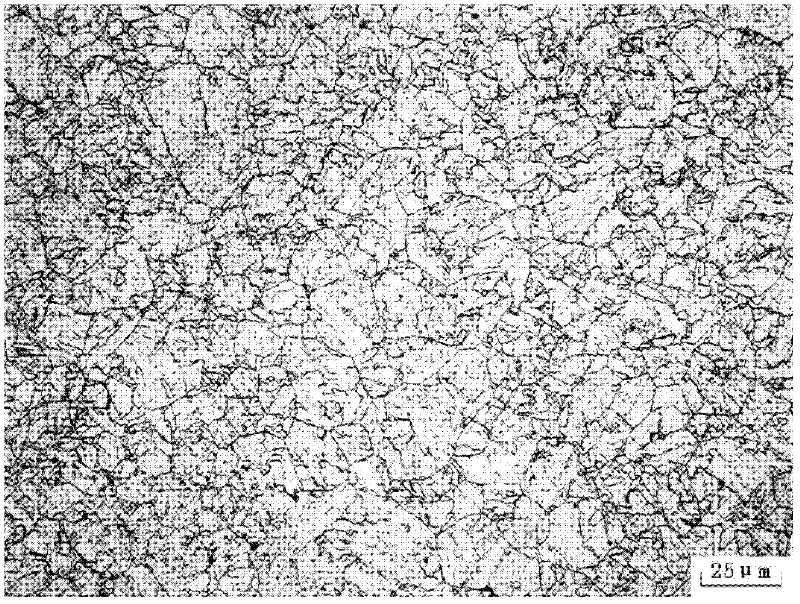

[0031] The test steel was smelted by silicon-killed deoxidation. During vacuum treatment, silicon deoxidation is added, aluminum is added to the molten steel after vacuum treatment and before pouring, the mass fraction of aluminum element is controlled to be 0.02-0.04%, the mass fraction of nitrogen element is 0.005-0.015%, and the mass fraction of silicon element is 0.1-0.3 %, the specific chemical composition is shown in Table 3. After the test steel was forged and opened at 1150°C, two normalizing heat treatment processes were adopted: furnace was charged at 400°C and heated at 150°C / h to 900°C for 5 hours, then air-cooled to room temperature, followed by 640°C for 8 hours, air-cooled to room temperature. Cut samples for metallographic analysis, metallographic structure and grain size see image 3 . The same batch of samples were subjected to quenching and tempering treatment and simulated post-weld stress relief heat treatment, and processed into tensile and impact samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com