Method for testing thermo-oxidative ageing degree of polyethylene material

A detection method and a technology of thermal oxidative aging, which are used in the analysis of materials, material analysis through resonance, and measurement devices, etc., which can solve the problems of large sample size, complex sample preparation process, and large accidental factors in test results, and achieve high performance. Evaluate the effect of accuracy, reliable information, and convenient and fast detection process

Inactive Publication Date: 2010-08-25

ZHEJIANG UNIV

View PDF3 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The chance factor of the test results of this method is very large, and it requires a relatively complicated sample preparation process, and the required sample volume is large.

It can be seen that the above three methods are not universally applicable.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

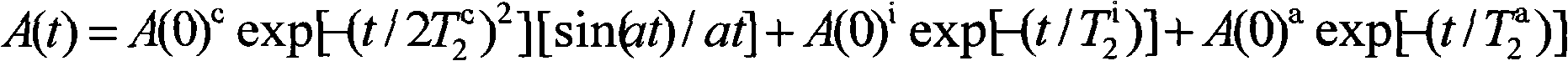

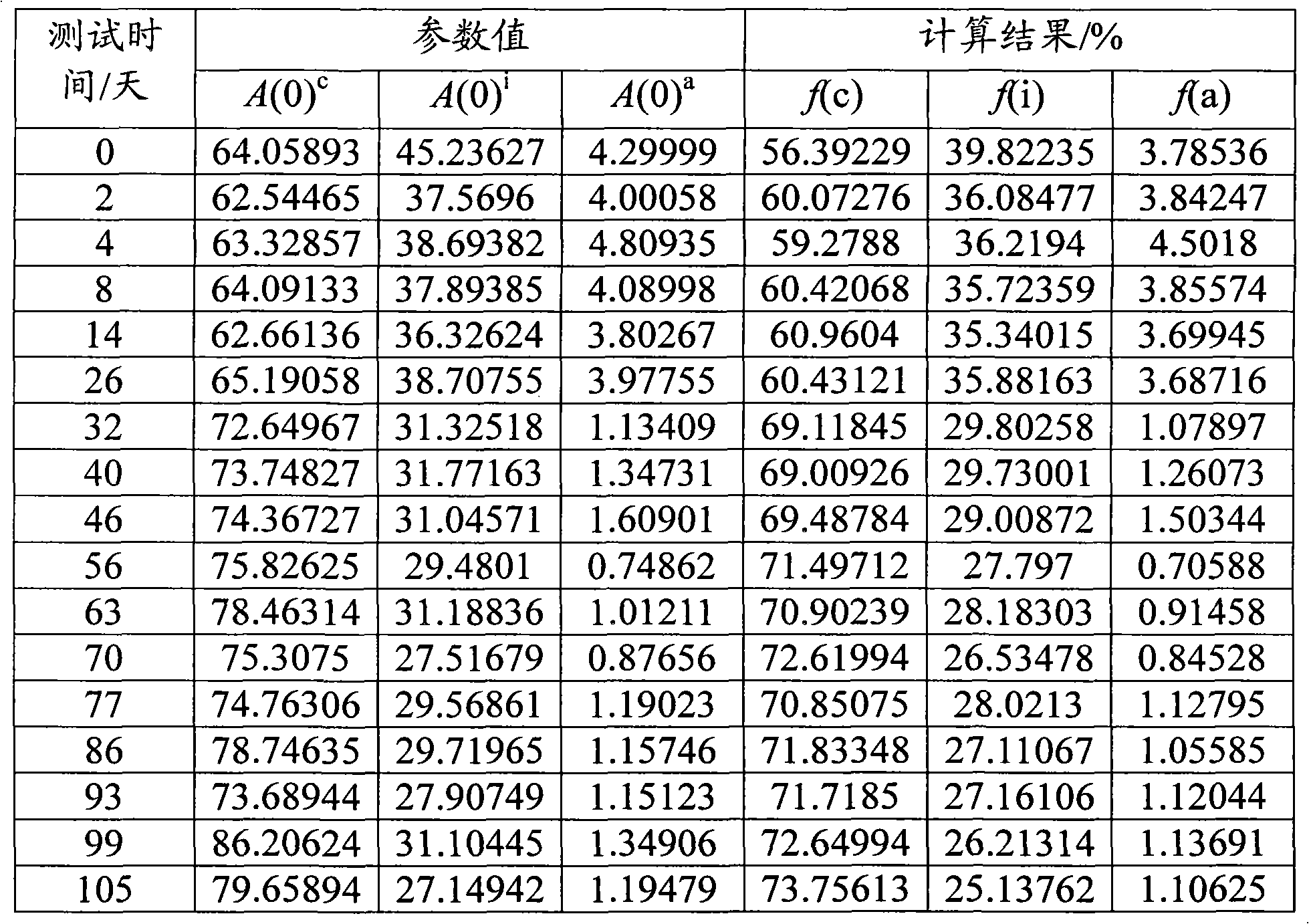

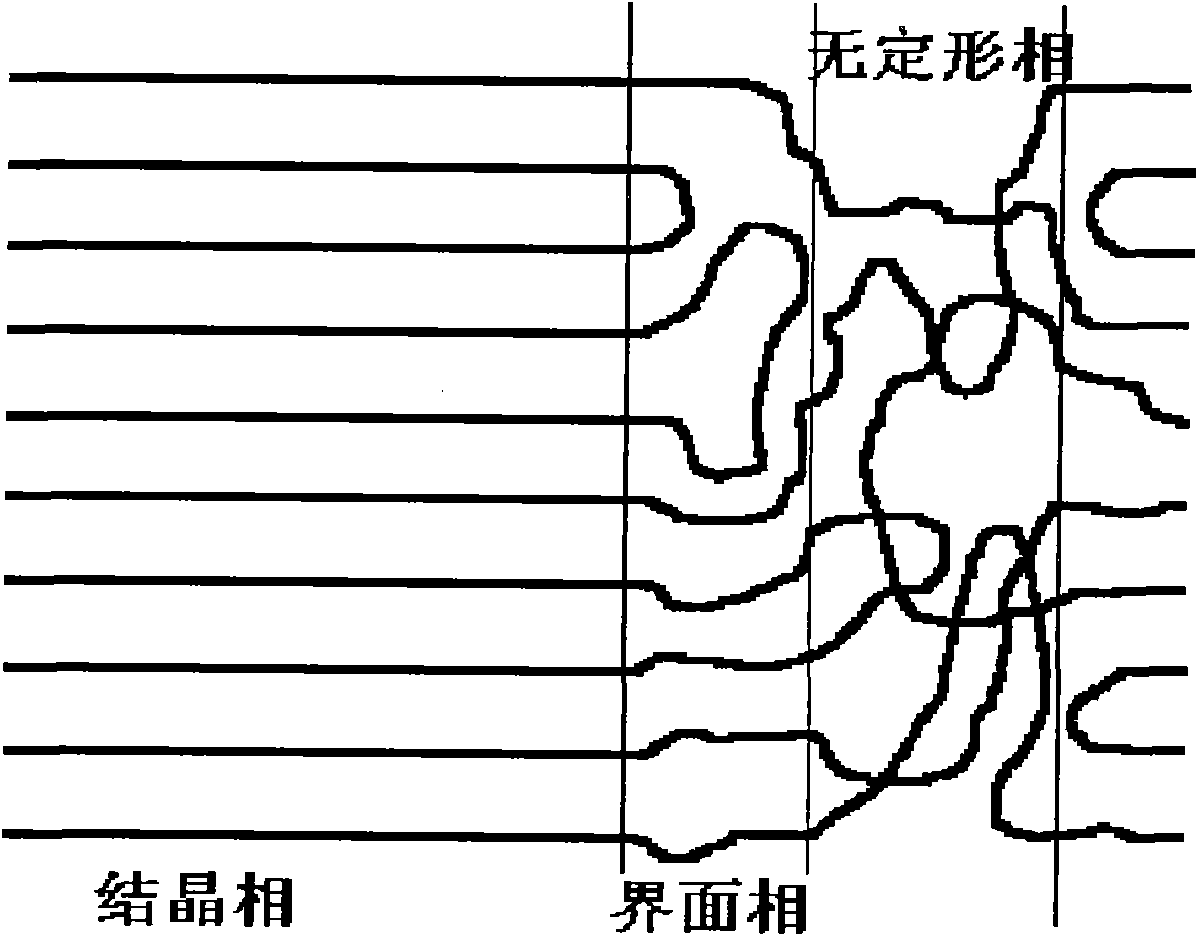

The invention discloses a method for testing the thermo-oxidative ageing degree of a polyethylene material, which comprises: (1) testing the molecular motion performance and condensed-state structure distribution of the polyethylene material; (2) calculating an aging factor, crystal phase mass percent content, interface mass percent content and amorphous phase mass percent content according to the result of test of the step (1) ; and (3) determining the aging degree of the polyethylene material according to the result of the calculation of the step (2). Compared with the traditional test method, the method of the invention has the advantages of convenience, quickness, high accuracy, small sample number, no damages to materials in use and wide application range.

Description

technical field The invention belongs to the field of performance detection of polymer materials, in particular to a detection method for thermal oxygen aging degree of polyethylene materials. Background technique Polyethylene is one of the general-purpose plastic products with the largest output and consumption in the world today. It is odorless, non-toxic, has excellent low temperature resistance (the lowest operating temperature can reach -70 ~ -100 ° C), good chemical stability, can withstand the erosion of most acids and alkalis, is insoluble in common solvents at room temperature, and has low water absorption. , excellent electrical insulation performance, very wide range of uses, mainly used to manufacture films, containers, pipes, monofilaments, wires and cables, daily necessities, etc., and can be used as high-frequency insulation materials for TVs, radars, etc. However, polyethylene is very sensitive to the environment, especially poor heat aging resistance. Comm...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N24/00

Inventor 阳永荣施小妹王靖岱蒋斌波范丽娜历伟杜丽君

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com