Polyamide6-graphene quantum dot/carbon nanotube anti-static fiber and preparation

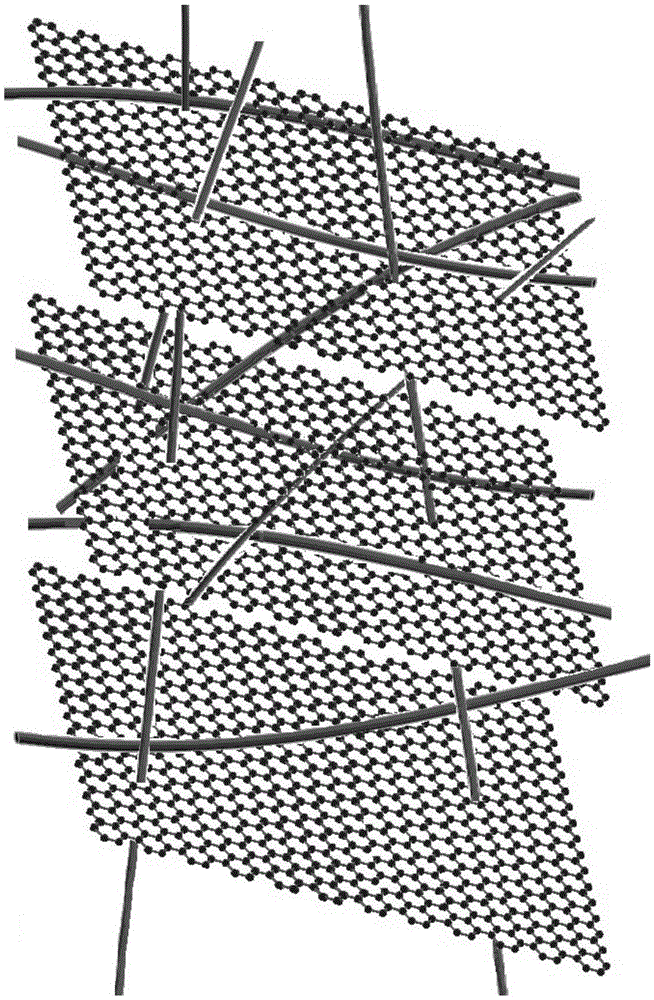

A technology of graphene quantum dots and anti-static fibers, which is applied in the manufacture of conductive/anti-static filaments and single-component polyamide artificial filaments. It can solve the problems of insufficient transparency of carbon nanomaterial dispersed fibers and reach the edge The effect of rich structure, excellent electrical conductivity, and small radial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of polyamide 6-graphene quantum dot / carbon nanotube antistatic fiber, comprising the following steps:

[0027] 1. Preparation of graphene quantum dots / carbon nanotubes (GQD / CNT) composites

[0028] (1) Take 8g of graphene quantum dots and 4g of nonylphenol polyoxyethylene ether (OP-10), dissolve them in 488g of deionized water, and disperse them by ultrasonic (using an ultrasonic cell disruptor with a power of 2000W) to obtain uniform dispersion Graphene quantum dot aqueous solution;

[0029] (2) Add 4g of carbon nanotubes, 4g of nonylphenol polyoxyethylene ether (OP-10), and 492g of deionized water to (1), and then filter through ultrasonic dispersion with an ultrasonic cell disruptor (power 2000W) and centrifugation at 1000g , to obtain a uniformly dispersed GQD / CNT mixture. The graphite sheets of the graphene quantum dots used in this step are 1 to 3 layers, with a size of 10 to 100 nm, and the carbon nanotubes are single-walled carbon nanotube...

Embodiment 2

[0039] A preparation method of polyamide 6-graphene quantum dot / carbon nanotube antistatic fiber, comprising the following steps:

[0040] 1. Preparation of graphene quantum dots / carbon nanotubes (GQD / CNT) composites

[0041] (1) Get graphene quantum dot 10g, sodium lauryl sulfate 10g, be dissolved in the deionized water of 480g, through homogeneous dispersion (using super high pressure homogenizer JN-10HC, its power 2500W), obtain the evenly dispersed Graphene quantum dot aqueous solution;

[0042] (2) Add 2g of carbon nanotubes, 4g of sodium lauryl sulfate, and 494g of deionized water to (1), ultrasonically disperse with an ultrasonic cell disruptor (power 1000W), and filter after centrifugal force at 1000g to obtain evenly dispersed GQD / CNT mixed solution. The graphite sheets of the graphene quantum dots used in this step are 1 to 3 layers, with a size of 10 to 100 nm, and the carbon nanotubes are single-walled carbon nanotubes with a diameter of 2 to 10 nm and a length ...

Embodiment 3

[0052] A preparation method of polyamide 6-graphene quantum dot / carbon nanotube antistatic fiber, comprising the following steps:

[0053] 1. Preparation of graphene quantum dots / carbon nanotubes (GQD / CNT) composites

[0054] (1) Get graphene quantum dot 6g, alkylphenol polyoxyethylene ether 6g, be dissolved in the deionized water of 488g, through ultrasonic dispersion (using ultrasonic cell breaker, its power 4000W), obtain the graphene quantum dot of uniform dispersion aqueous solution;

[0055] (2) Add 10g of carbon nanotubes, 10g of alkylphenol polyoxyethylene ether, and 480g of deionized water to (1), and ultrasonically disperse them with an ultrasonic cell disruptor (power 2000W), filter them after centrifugal force at 1000g, and obtain evenly dispersed GQD / CNT mixed solution. The graphite sheets of the graphene quantum dots used in this step are 1 to 3 layers, with a size of 10 to 100 nm, and the carbon nanotubes are single-walled carbon nanotubes with a diameter of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com