Method for preparing high strength and high plasticity aluminum-magnesium alloy of mixcrystal structure

A magnesium alloy and mixed crystal technology is applied in the field of preparation of high-strength plastic mixed-crystal structure aluminum-magnesium alloys, which can solve the problems of low plasticity of high-strength aluminum-magnesium alloys and limit industrial applications, and achieves improved strength, improved work hardening and Plastic deformation ability, the effect that is beneficial to recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

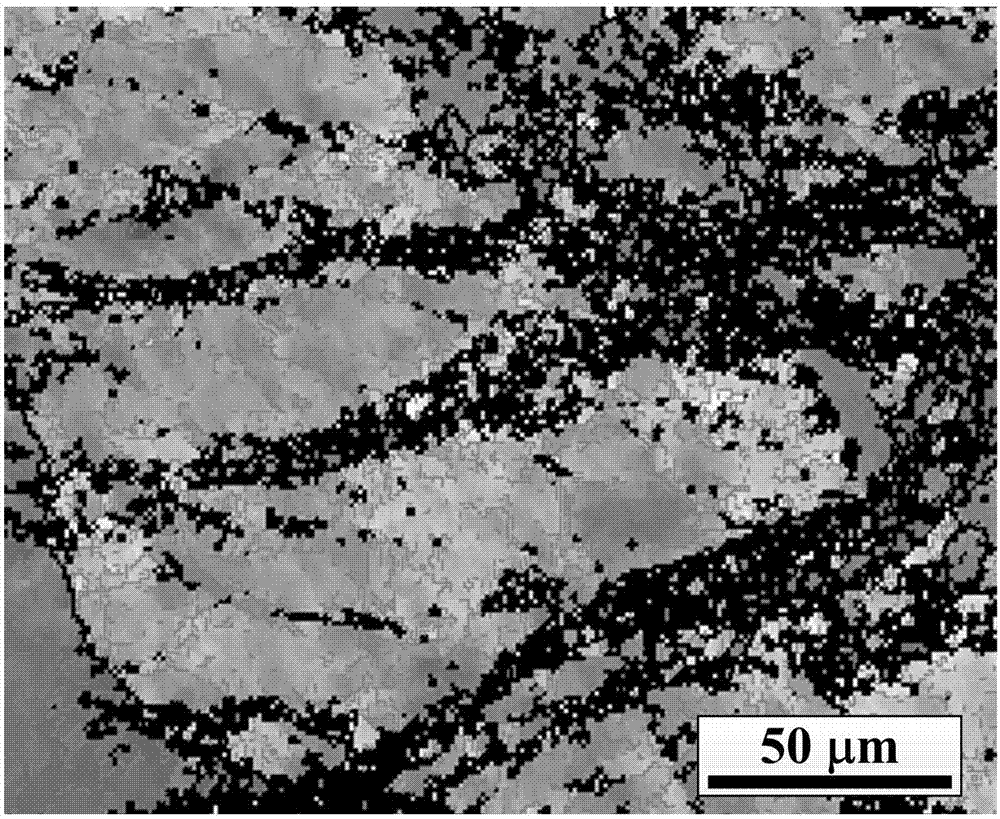

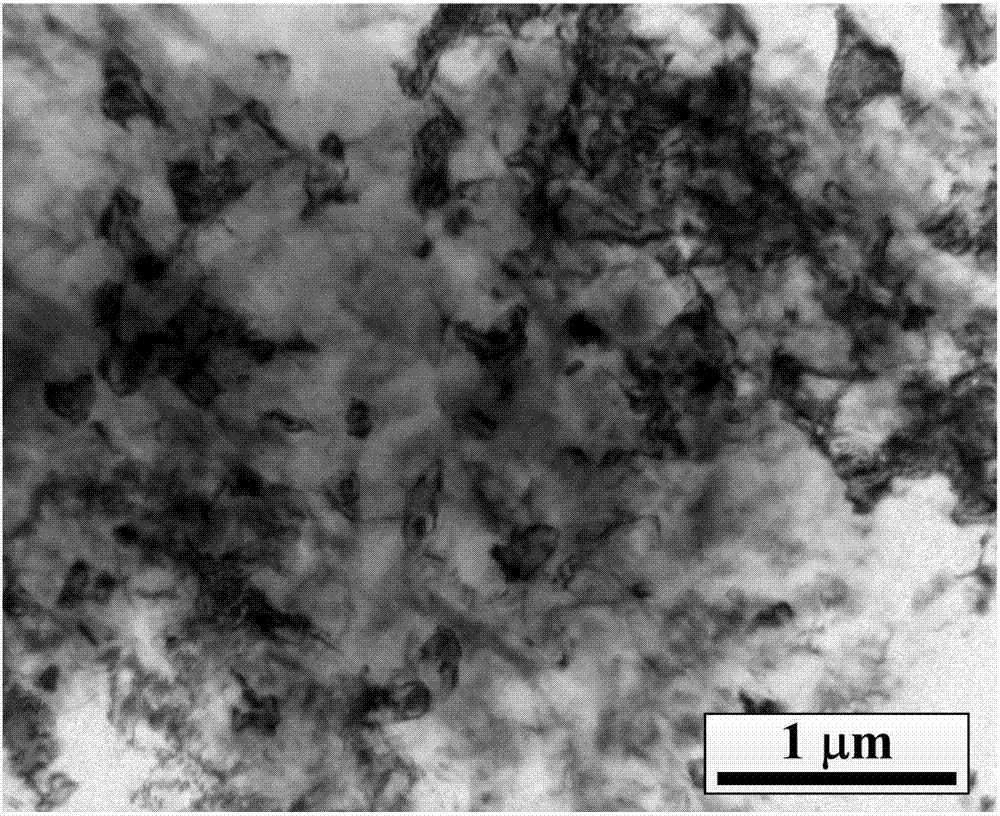

Image

Examples

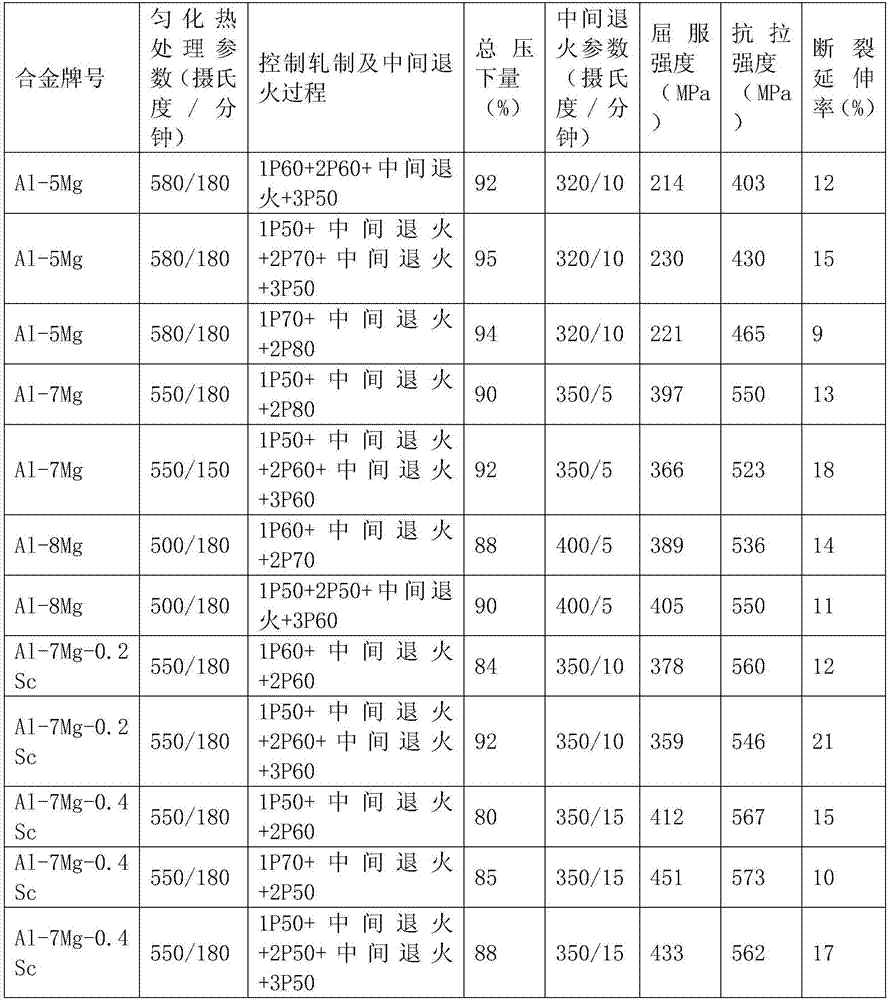

Embodiment 1

[0020] (1) High-temperature homogenization treatment: The cast Al-5Mg alloy is subjected to a homogenization heat treatment at 580 degrees Celsius for 180 minutes to eliminate macro-segregation of elements in the as-cast structure and achieve high solid solution of alloying elements;

[0021] (2) Intermediate annealing assisted large-reduction controlled rolling: process the Al-5Mg alloy after homogeneous heat treatment into a sample of a certain size, and then carry out rolling deformation with a single-pass reduction of 60%. No microcracks occur; place the deformed sample in an air heating furnace or a salt bath furnace, and keep it warm at 320 degrees Celsius for 10 minutes to eliminate internal stress and form a recovered or recrystallized structure, and then put the sample in cold water to cool down to room temperature; The annealed sample was subjected to rolling deformation with a reduction of 70% at room temperature, that is, the total reduction reached 88%, and no obvi...

Embodiment 2

[0024] (1) High-temperature homogenization treatment: The cast Al-7Mg alloy is subjected to a homogenization heat treatment at 550 degrees Celsius for 180 minutes to eliminate macro-segregation of elements in the as-cast structure and achieve high solid solution of alloying elements;

[0025] (2) Intermediate annealing assisted large-reduction controlled rolling: process the Al-7Mg alloy after homogeneous heat treatment into a sample of a certain size, and then carry out rolling deformation with a single-pass reduction of 70%. No micro-cracks are produced; place the deformed sample in an air heating furnace or a salt bath furnace, and keep it warm at 350 degrees Celsius for 5 minutes to eliminate internal stress and form a recovered or recrystallized structure, and then put the sample in cold water and cool it down to room temperature; The annealed sample was subjected to rolling deformation with a reduction of 70% at room temperature, that is, the total reduction reached 91%, ...

Embodiment 3

[0028] (1) High-temperature homogenization treatment: The cast Al-7Mg-0.2Sc alloy ingot is subjected to a homogenization heat treatment at 550 degrees Celsius for 180 minutes to eliminate macro-segregation of elements in the as-cast structure and achieve high solid solution of alloying elements;

[0029] (2) Intermediate annealing assisted large-reduction controlled rolling: the Al-7Mg-0.2Sc alloy after homogeneous heat treatment was processed into a rolling sample of a certain size, and then rolled and deformed in two passes. The lower weight is 50%, and no microcracks are produced on the sample surface; the rolled sample is placed in an air heating furnace or a salt bath furnace, and is kept at 350 degrees Celsius for 10 minutes to eliminate internal stress, and then the sample is put into cold water to Room temperature; the sample after intermediate annealing is subjected to rolling deformation at room temperature with a reduction of 60% in a single pass, that is, the total ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com