Method for removing remelting layer in electric spark drilling for single crystal turbine blade

A turbine blade and electric spark technology is applied in the field of remelting layer removal of single crystal turbine blade electric spark hole making, which can solve the problems of low efficiency, influence of blade cavity, unfeasible heat treatment method, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

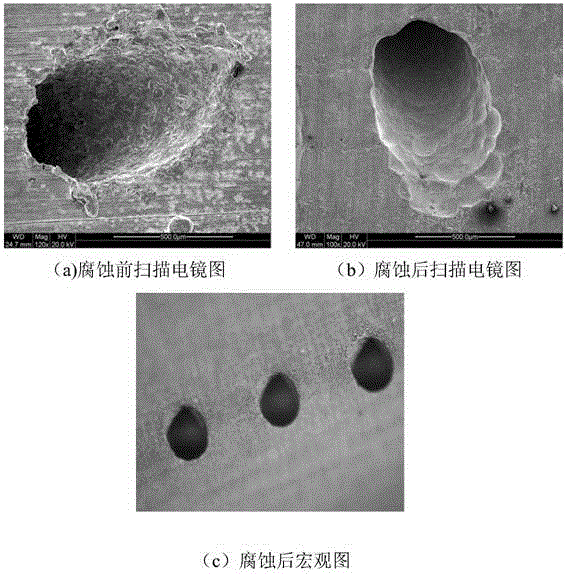

[0022] The specific process of a method for removing the remelted layer of single crystal turbine blades by EDM is: mixing hydrochloric acid, water, and hydrogen peroxide in a volume ratio of 100:44:25 to obtain corrosive liquid, and pass DD6 single crystal blades through EDM After the hole, put it into a container filled with corrosive liquid, and then place it in an ultrasonic wave with a power of 2400W to vibrate, and the vibration time is 30min. After that, under observation under a metallographic microscope, the remelted layer in the air film holes on the single crystal blade was completely removed, and the effect was obvious. figure 1 , figure 1 (a) is the scanning electron micrograph before corrosion, figure 1 (b) is the scanning electron micrograph after corrosion, figure 1 (c) is a macroscopic view after corrosion, from which it can be seen that the remelted layer has been completely removed.

Embodiment 2

[0024] The specific process of a method for removing the remelted layer of single crystal turbine blades by EDM is: mixing hydrochloric acid, water, and hydrogen peroxide in a volume ratio of 91:43:22 to obtain a corrosive liquid, and pass the DD6 single crystal blade through the EDM process After the hole, put it into a container filled with corrosive liquid, and then place it in an ultrasonic wave with a power of 2400W and vibrate for 20min. After that, under a metallurgical microscope, the remelted layer in the air film holes on the single crystal blade was completely removed.

Embodiment 3

[0026] The specific process of a method for removing the remelted layer of single crystal turbine blades by EDM is: mixing hydrochloric acid, water, and hydrogen peroxide in a volume ratio of 93:41:20 to obtain corrosive liquid, and pass the DD6 single crystal blade through the EDM process After the hole, put it into a container with corrosive liquid, and then place it in an ultrasonic wave with a power of 2400W to vibrate, and the vibration time is 40min. After that, under a metallurgical microscope, the remelted layer in the air film holes on the single crystal blade was completely removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com