Electro-catalyst Pt/amTiO2/rGO and preparation method

An electrocatalyst and fossil technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve current density errors, accelerate rGO corrosion, and unsatisfactory catalytic effects And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Prepare graphene oxide (GO) hydrosol with a concentration of 16.4 mg / mL.

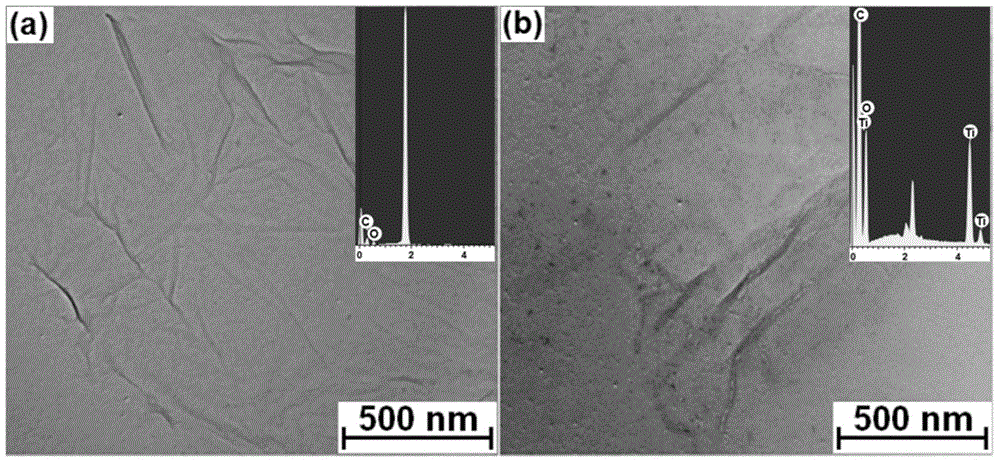

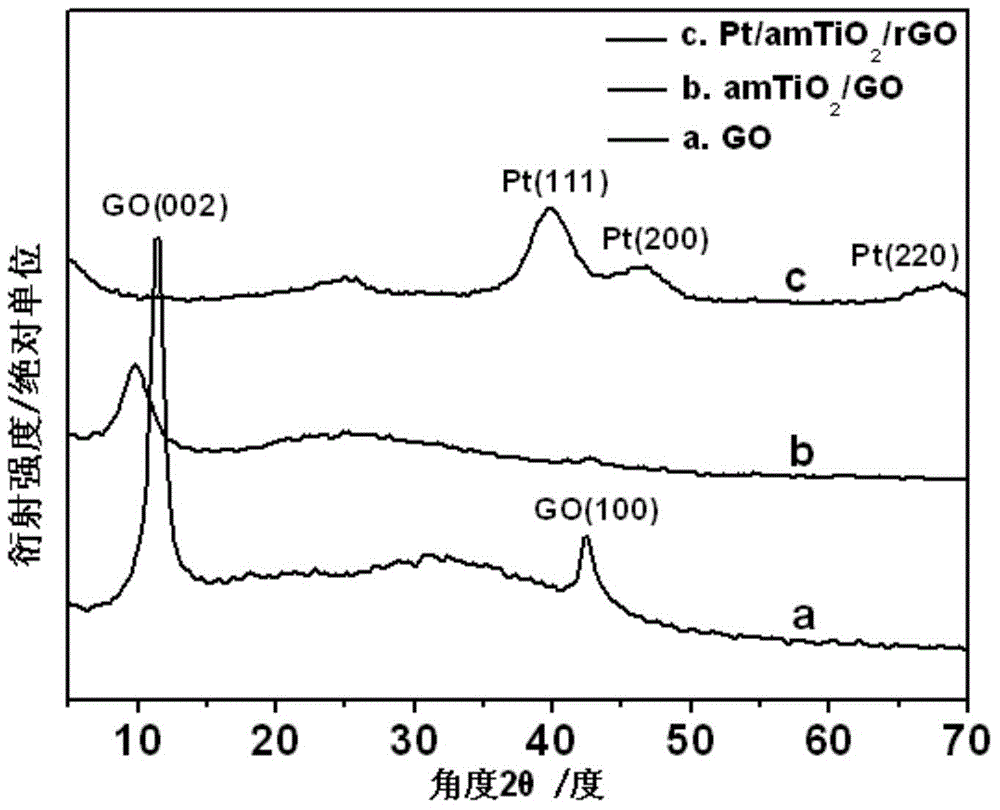

[0026] Step 2: Preparation of amTiO by sol-gel method 2 / GO, sonicate the mixture of 40mL absolute ethanol, 7.8mL deionized water, 360μL glacial acetic acid and 12.2mL GO hydrosol (see step 1) at room temperature for 4h to disperse the mixture evenly; The mixture of water ethanol and 186 μL isopropyl titanate was sonicated at room temperature for 0.5 h; under the condition of magnetic stirring at 25 °C, drop B liquid into A liquid drop by drop, and continue to stir for 1 h to obtain TiO 2 -GO sol; the TiO 2 -GO sol was aged in a water bath at 25°C for 168 hours to obtain amTiO 2 / GO, grind to powder, collect for later use. where amTiO 2 at amTiO 2 Theoretical mass fraction in / GO is 20 wt%.

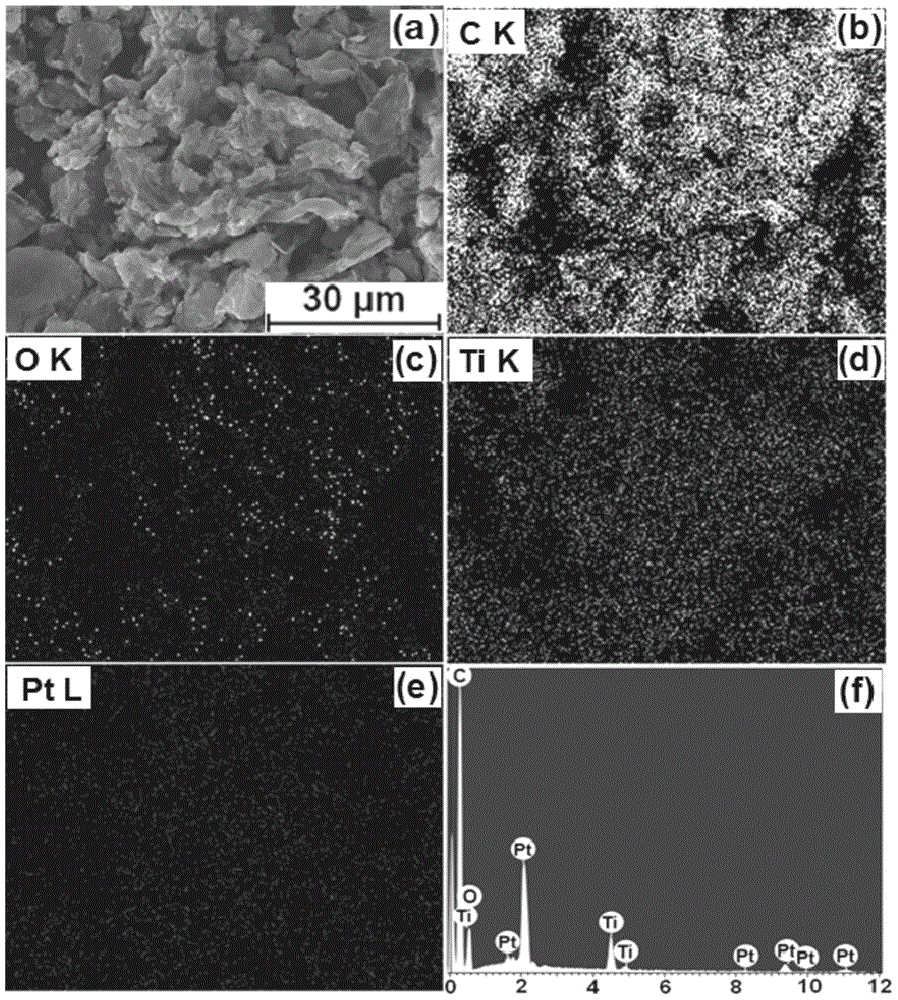

[0027] Step 3: Preparation of Pt / amTiO by impregnation reduction method 2 / rGO electrocatalyst, 40mg amTiO 2 / GO (see step 2) was added to 40mL ethylene glycol, 7.90mL deionized water and 2.1...

Embodiment 2

[0029] The present embodiment is with embodiment 1 except following feature:

[0030] 40mg amTiO 2 / GO was added to 40mL ethylene glycol, 7.35mL deionized water and 2.65mL 0.019MH 2 PtCl 6 In the mixed liquid of aqueous solution, ultrasonic 0.5h was obtained to obtain the suspension; the obtained suspension was put into an oil bath at 120°C, and magnetically stirred for 24 hours under the condition of condensation and reflux to obtain a black suspension; the black suspension was filtered and washed several times for separation A black solid was obtained, and then the black solid was vacuum-dried at 40°C for 24 hours, ground to a powder and collected, recorded as Pt / amTiO 2 / rGO. Wherein the theoretical mass fraction of noble metal Pt in the catalyst is 20.0wt%.

Embodiment 3

[0032] This example is the same as Example 2 except for the following features: the suspension was reacted in an oil bath at 120° C. for 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com