Rapid metallographic determination method for grain size of GCr15 steel bearing assembly

A technology of bearing components and measurement methods, which is applied in the field of rapid metallographic determination of grain size of GCr15 bearing components, can solve the problem of the difficulty in clearly displaying the grain boundary outline of GCr15 bearing components, the inability to measure the grain size of GCr15 bearing components, and the time consumption of the corrosion process Long and other problems, to achieve the effect of efficient and accurate determination of grain size, clear outline of grain boundary, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

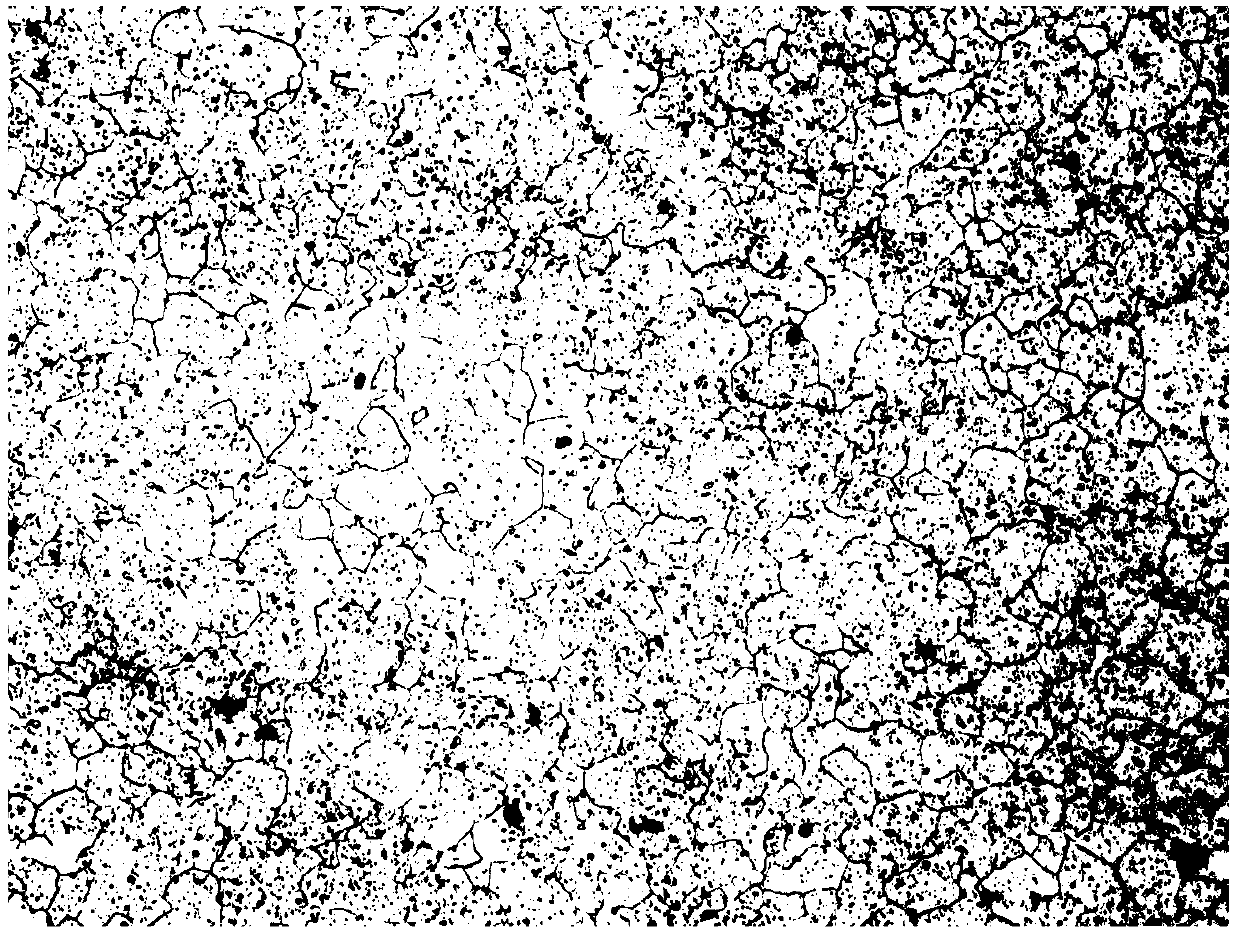

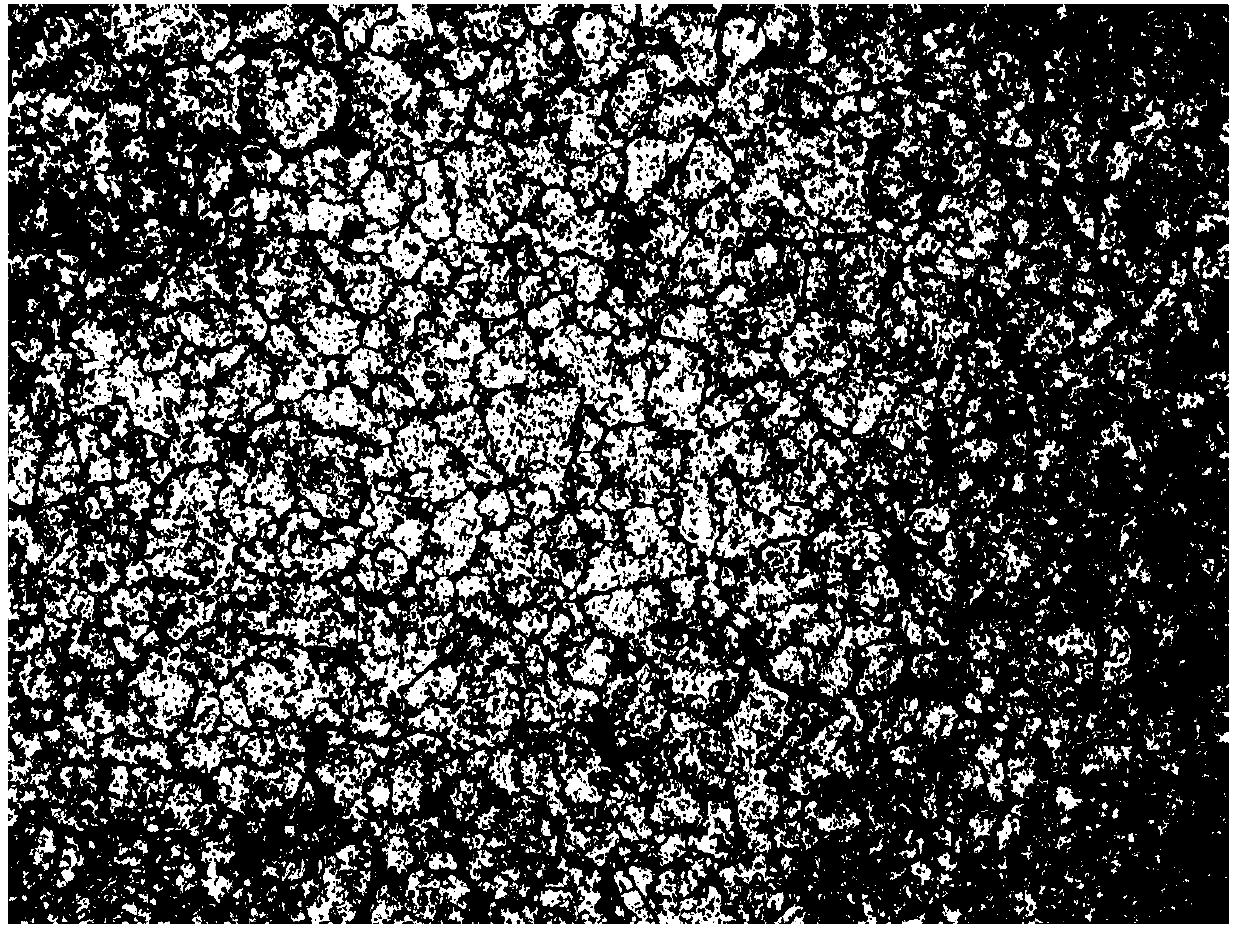

[0020] Cut a GCr15 bearing ring into a sample of 8mm×10mm10×4mm, after inlaying, carry out rough grinding, fine grinding and polishing, and clean and dry. Its grain size metallographic determination is realized according to the following steps:

[0021] 1) Preparation of corrosion solution:

[0022] ①. Take 80ml of distilled water, heat at a heating rate of 8°C / min, add 3.5g of picric acid evenly during the heating process, and keep stirring;

[0023] ②. When the picric acid solution is heated to a boiling state and is supersaturated, add 0.2 g of sodium dodecylbenzenesulfonate and stir evenly;

[0024] ③. Control the temperature of the solution at 90±5°C to keep the solution in a slight boiling state to obtain a corrosion solution;

[0025] 2) Corrosion of bearing assembly samples:

[0026] ①. Immerse the GCr15 bearing ring sample that has been roughly ground, finely ground, polished, cleaned and dried in the corrosion solution, keep the corroded surface in full and unifor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com