Sacrificial anode for deep sea environment and manufacturing method thereof

A sacrificial anode, deep-sea environment technology, applied in the field of sacrificial anode materials, can solve the problems of increased alloy manufacturing cost, marine environmental pollution, particle shedding, etc., and achieve the effect of reducing anode cost and high current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

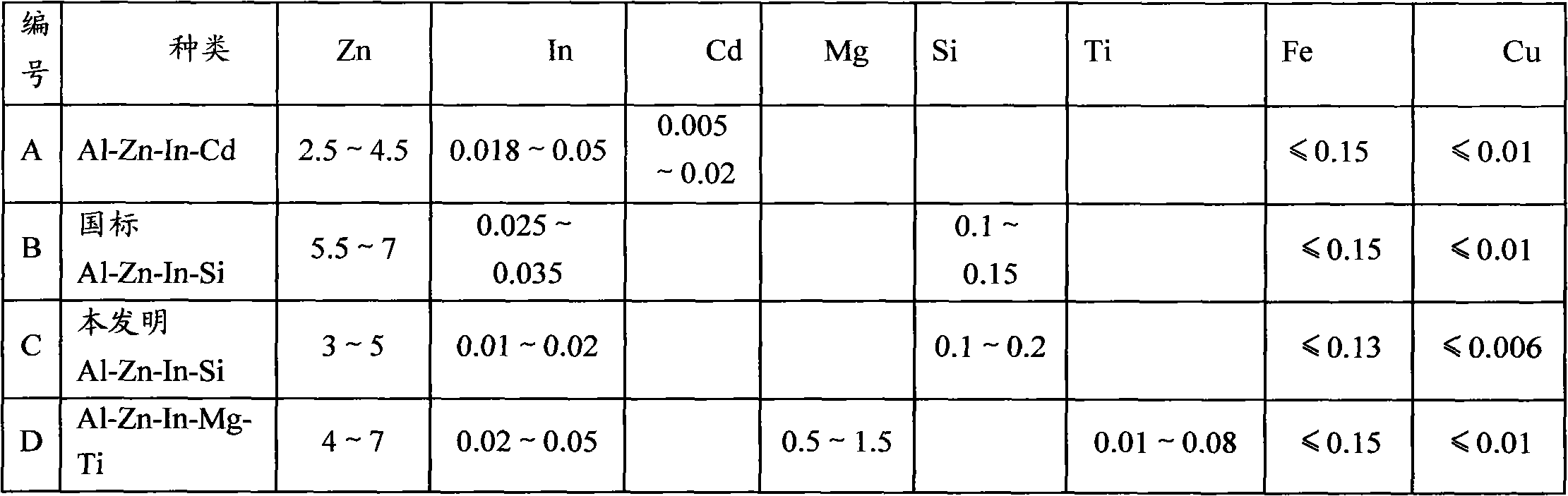

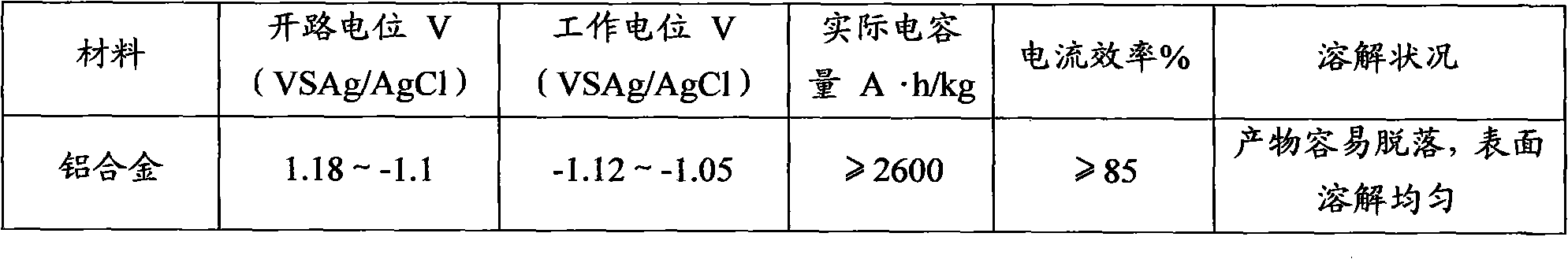

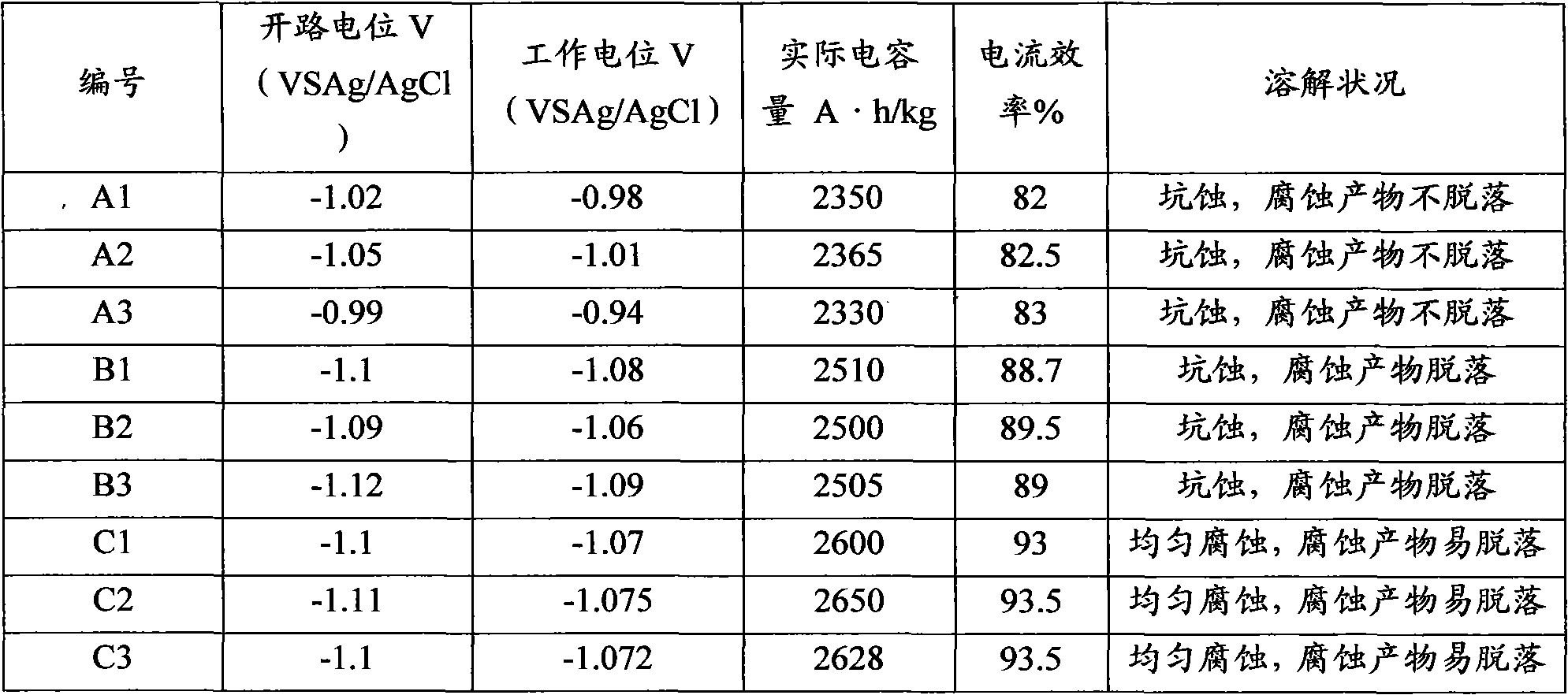

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: The label is sample C1.

[0032] Aluminum is used as raw material, and elements zinc, indium, and silicon are added, and the weight percentage of each component is as follows: zinc 3.5%, indium 0.015%, silicon 0.15%; total amount of impurities ≤ 0.16%, among which, impurity iron ≤ 0.12%, Impurity copper ≤ 0.005%; the balance is aluminum. First, weigh aluminum ingots, zinc ingots, elemental indium and elemental silicon according to the mass percentage, and the total amount of impurities in the selected aluminum ingots is ≤0.16%; then wrap the indium and silicon with aluminum foil, and melt the aluminum ingots in a resistance furnace crucible at 750-800°C, then add zinc ingots, press the alloy element package into molten aluminum after melting, degassing, and slag removal, stir evenly after melting, remove slag, cast in a cast iron mold, let it cool naturally, and get Cast rod; process the cast rod into a φ16mm×48mm electrochemical performance test sample a...

Embodiment 2

[0033] Embodiment two: label is sample C2

[0034] Aluminum is used as raw material, and elements zinc, indium, and silicon are added, and the weight percentage of each component is as follows: zinc 4.0%, indium 0.01%, silicon 0.10%; total amount of impurities ≤ 0.16%, among which, impurity iron ≤ 0.13%, Impurity copper ≤ 0.004%; the balance is aluminum. First, weigh aluminum ingots, zinc ingots, elemental indium and elemental silicon according to the mass percentage, and the total amount of impurities in the selected aluminum ingots is ≤0.16%; then wrap the indium and silicon with aluminum foil, and melt the aluminum ingots in a resistance furnace crucible at 750-800°C, then add zinc ingots, press the alloy element package into molten aluminum after melting, degassing, and slag removal, stir evenly after melting, remove slag, cast in a cast iron mold, let it cool naturally, and get Cast rod; process the cast rod into a φ16mm×48mm electrochemical performance test sample and a...

Embodiment 3

[0035] Embodiment three: label is sample C3

[0036] Aluminum is used as raw material, and elements zinc, indium, and silicon are added, and the weight percentage of each component is as follows: zinc 4.5%, indium 0.02%, silicon 0.20%; total amount of impurities ≤ 0.16%, among which, impurity iron ≤ 0.13%, Impurity copper ≤ 0.006%; the balance is aluminum. First, weigh aluminum ingots, zinc ingots, elemental indium and elemental silicon according to the mass percentage, and the total amount of impurities in the selected aluminum ingots is ≤0.16%; then wrap the indium and silicon with aluminum foil, and melt the aluminum ingots in a resistance furnace crucible at 750~800℃, then add zinc ingots, after melting, degassing, and slag removal, press the alloy element package into the molten aluminum, stir evenly after melting, remove slag, cast in a cast iron mold, let it cool naturally, and get Cast rod; process the cast rod into a φ16mm×48mm electrochemical performance test sample a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com