Bentonite-loaded sulfurized nanoscale zero-valent iron composite material and preparation method and application thereof

A technology of nano-zero-valent iron and composite materials, applied in chemical instruments and methods, alkali metal compounds, inorganic chemistry, etc., can solve the problems of easy aggregation of nano-zero-valent iron and low activity of nano-zero-valent iron, and achieve strong reactivity , increase the adsorption performance, the vulcanization process is simple and pollution-free

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1, preparation of bentonite-supported sulfide nano-zero-valent iron composite material

[0057] 80mL ethanol, 20mL water, 0.5g bentonite and 2.415g FeCl 3 ·6H 2 O was added to the four-necked flask, stirred at 300rpm and nitrogen flow rate of 500mL / min for 30min, weighed 1.0133g of sodium borohydride and 0.08g of sodium hydroxide dissolved in 40mL of oxygen-free deionized water, and used a constant pressure funnel to Add 2 drops / second to the four-necked flask, and at the same time add 0.5mL 1mol / L Na at 1-2 drops / second 2 S solution. After reacting for 30 minutes, it was centrifuged and washed with anaerobic deionized water and ethanol solution respectively to obtain a bentonite-loaded sulfurized nano-zero-valent iron composite material with a sulfur-iron molar ratio of 0.056:1. The composite material was added into 50 mL of oxygen-free deionized water and sonicated for 5 min to obtain a 20 g / L solution.

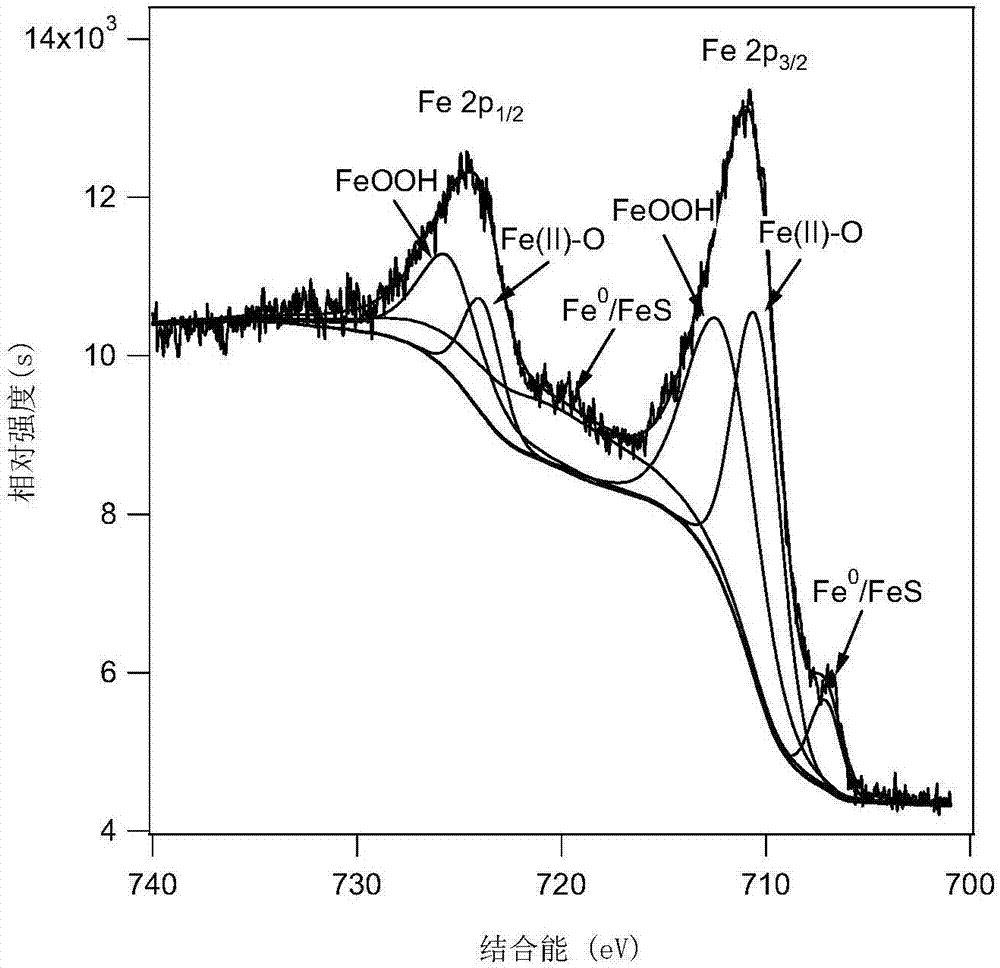

[0058] The X-ray photoelectron spectrum (XPS) of...

Embodiment 2

[0067] Embodiment 2, remove the application of 4-nitrophenol in waste water

[0068] The maximum ultraviolet absorption peak of 4-nitrophenol is 317nm (under acidic conditions).

[0069]According to a series of 4-nitrophenol solutions with known concentrations, measure the corresponding ultraviolet absorbance to obtain a standard curve of absorbance and concentration.

[0070] Utilize the composite material prepared in embodiment 1 and its comparative examples 1-3 to remove 4-nitrophenol in the pesticide wastewater, the concentration of 4-nitrophenol in the wastewater is 1.5mmol / L, the steps are as follows:

[0071] (1) Measure 1L of pesticide wastewater containing p-nitrophenol, place it in an open reactor, add 0.1420g of sodium sulfate (concentration 1mM), and adjust pH=6 with NaOH solution and HCl solution with a mass fraction of 20%;

[0072] (2) Add the composite materials prepared in Example 1 and Comparative Examples 1-3 respectively to the solution, so that the concen...

Embodiment 3

[0074] Embodiment 3, remove the application of orange yellow I in the waste water

[0075] The maximum ultraviolet absorption peak of Orange I is 476nm.

[0076] According to a series of orange I solutions with known concentrations, measure the corresponding ultraviolet absorbance to obtain a standard curve of absorbance and concentration.

[0077] Utilize the composite material prepared in Example 1 and Comparative Example 1 to remove orange I in printing and dyeing wastewater, the concentration of orange I in the wastewater is 100mg / L, the steps are as follows;

[0078] (1) Take 1L of orange yellow I simulated waste water and open reactor, add 0.1420g sodium sulfate (concentration 1mM), adjust pH=6.0 with NaOH and HCl solution with a mass fraction of 20%;

[0079] (2) Add the bentonite-loaded sulfide nano-zero-valent iron composite material prepared in Example 1 into the reactor, so that its concentration is 1.0g / L, the rotating speed is 400r / min, and the room temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com